Coupling adhesion device

A coupling and bonding technology, used in mechanical equipment, connecting components, material gluing, etc., can solve the problems of complex operation, low processing efficiency, low bonding accuracy, etc., to achieve simple operation, improve processing efficiency, and uniform thickness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0033] It should be noted that the embodiments in this application and the features in the embodiments can be combined with each other if there is no conflict. Hereinafter, the present invention will be described in detail with reference to the drawings and in conjunction with the embodiments.

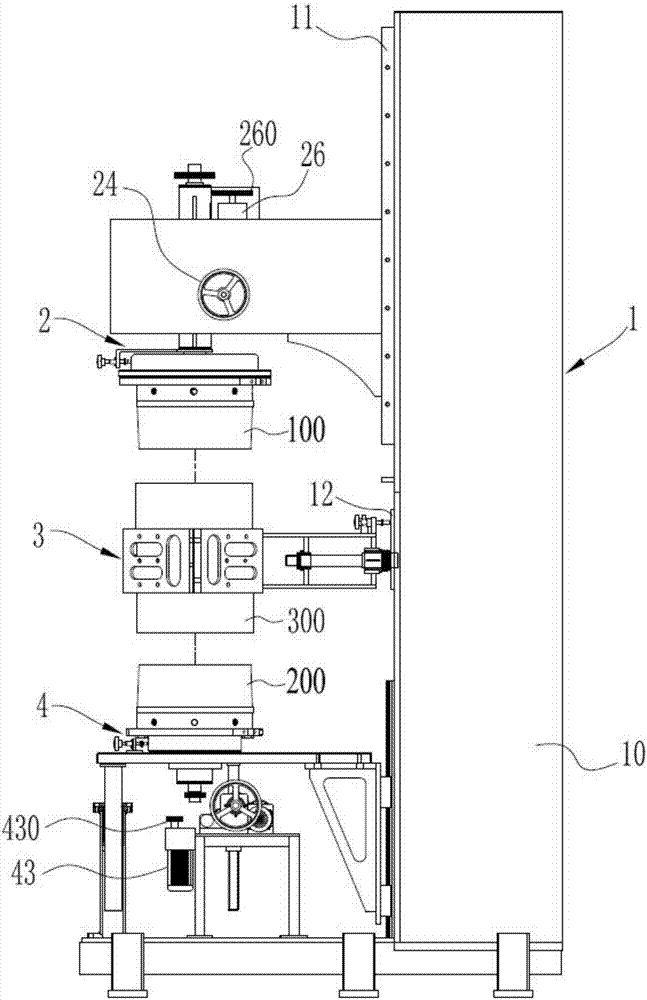

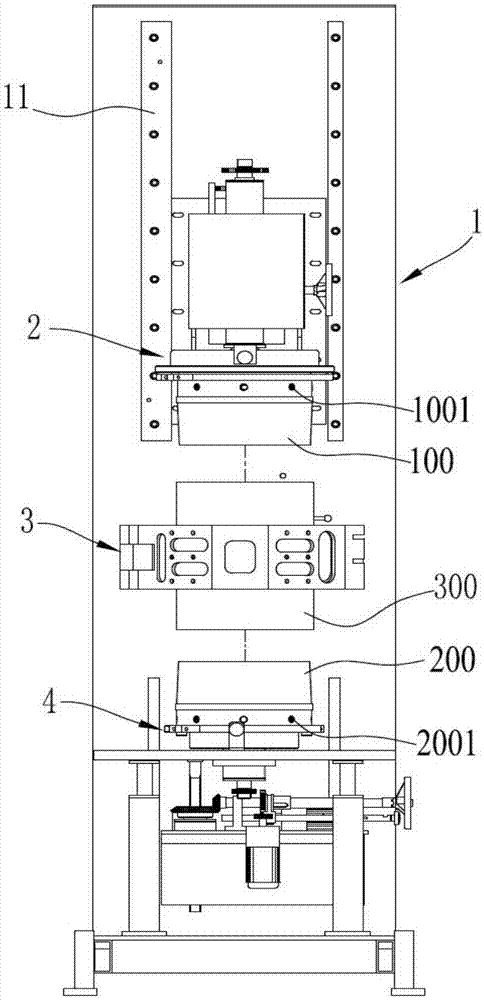

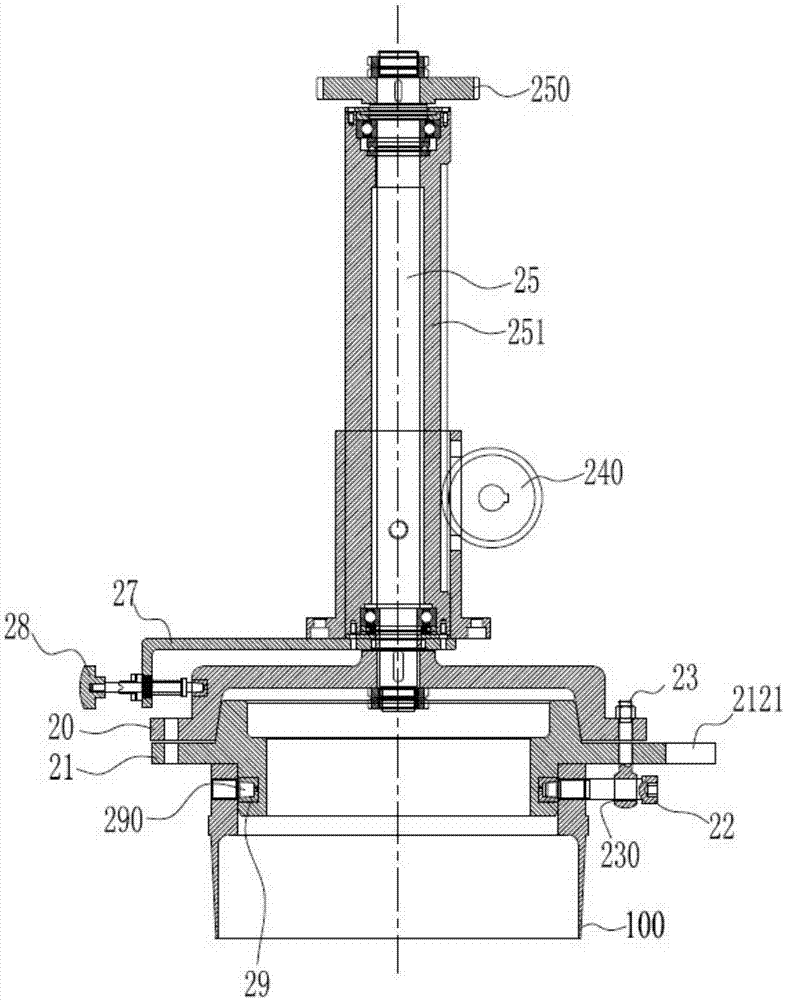

[0034] Reference figure 1 with figure 2 , The preferred embodiment of the present invention provides a coupling bonding device for bonding the upper flange 100, the lower flange 200 of the coupling and the middle plexiglass cylinder 300 together, including the machine tool 1, The machine tool 1 is provided with an upper lifting rotating member 2, a middle movable clamp 3 and a lower lifting rotating member 4. Among them, the upper lifting rotating member 2 is used to install the upper flange 100, driving the upper flange 100 to rotate along its own axis, and driving the upper flange 100 to move up and down to be assembled on the plexiglass cylinder 300; the lower lifting rotating member ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap