Brake outer circle runout detection mechanism

A detection mechanism and jump detection technology, which is applied in the direction of mechanical roughness/irregularity measurement, can solve the problems of inaccurate detection data and low operation efficiency, achieve high detection accuracy, eliminate errors, and improve detection accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

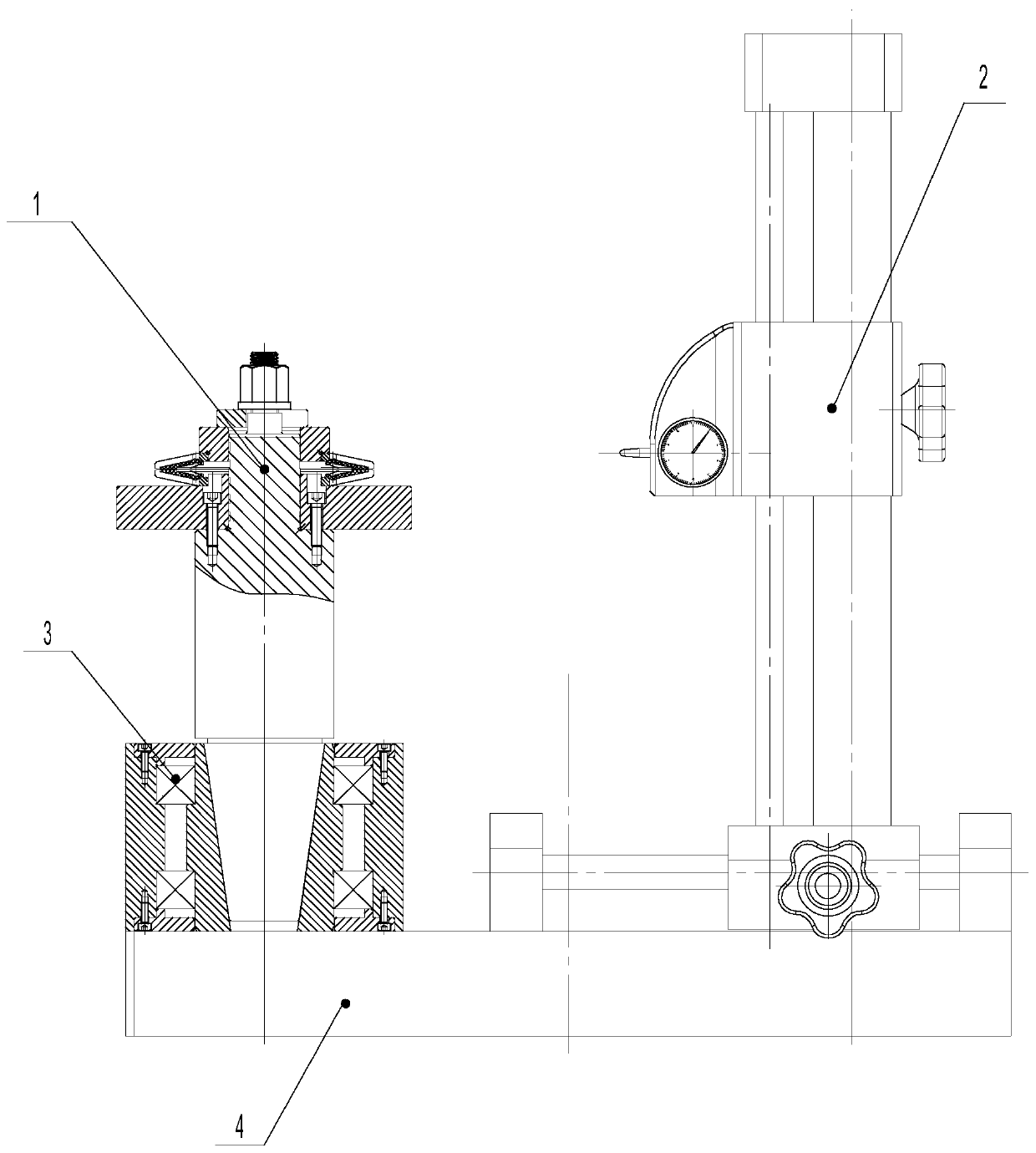

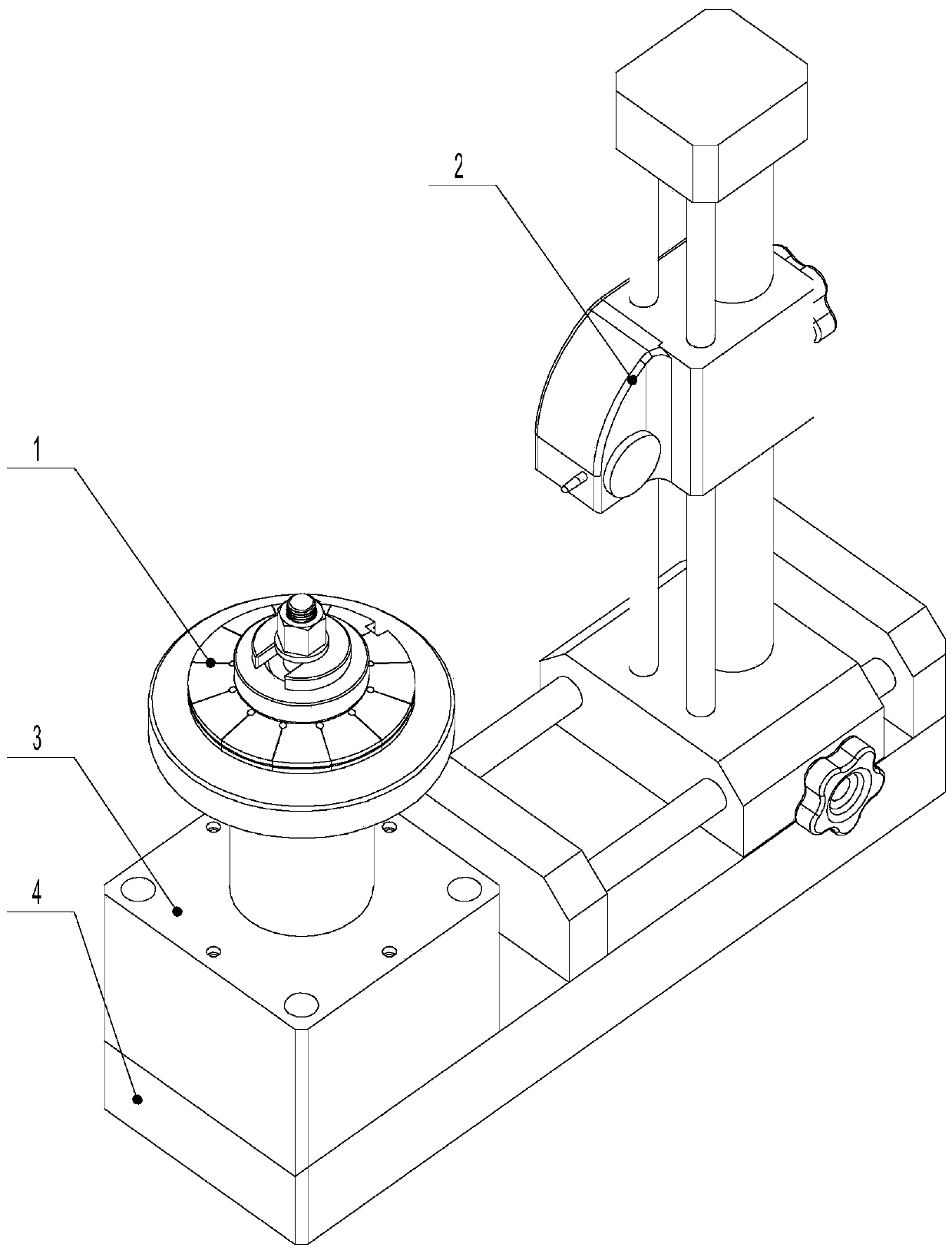

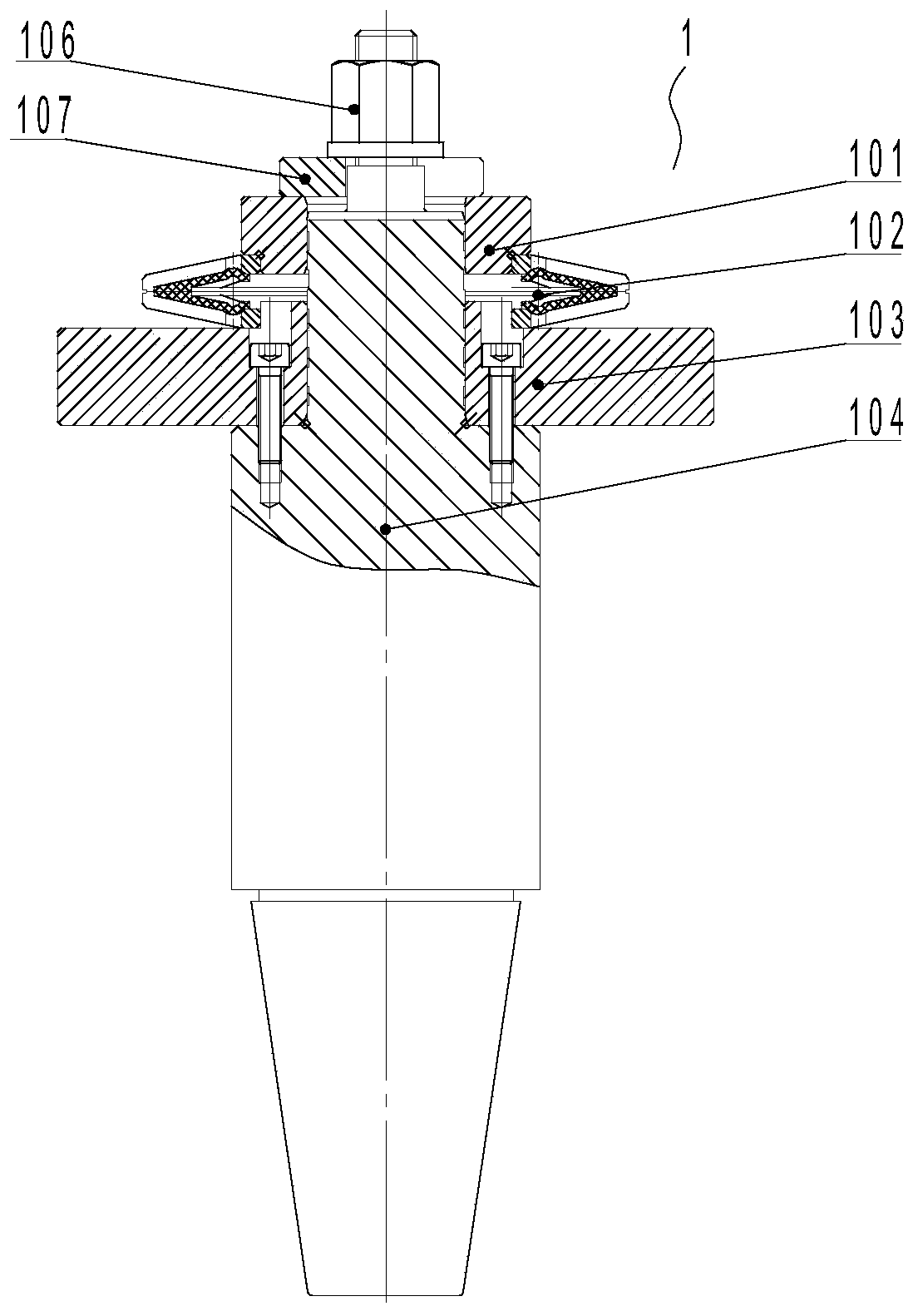

[0053] A brake outer circle runout detection mechanism, including a core expansion positioning mechanism 1, a runout detection mechanism 2, a taper sleeve swivel seat 3, and a base 4, wherein:

[0054] The core expansion positioning mechanism 1 includes a core fixing platen 101, a spring expansion plate 102, a positioning base plate 103, and a mandrel 104; It is also tightly connected with the mandrel 104 by fastener bolts, and the upper end surface of the positioning base plate 103 is in contact with the end of the inner hole of the workpiece 5; Spring rises sheet 102, and spring rises sheet 102 and the endoporus aperture of workpiece 5 and cooperates, and this spring rises sheet 102 and is also provided with limit groove, and described positioning base plate 103 is installed limit pin 105, and this limit pin 105 Cooperate with the limit groove to ensure that the spring riser 102 cannot slip and turn. The upper end of the mandrel 104 is pressed and fixed on the centering pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com