Method for estimating ultimate bearing capacity of pile-tip-grouted over-length pile

An ultimate bearing capacity and post-grouting technology, applied in the field of geotechnical engineering, can solve the problems of large discreteness of bearing capacity, difficult to estimate accurately, and change of load transfer mechanism of super-long piles, so as to achieve accurate estimation results and simple estimation methods. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0045] [Example 2] On the basis of Example 1, this example combines a specific engineering case (S22 super-long pile of a project in Hongqiao, Shanghai) to estimate the ultimate bearing capacity of the post-grouting super-long pile at the pile end. Specific instructions:

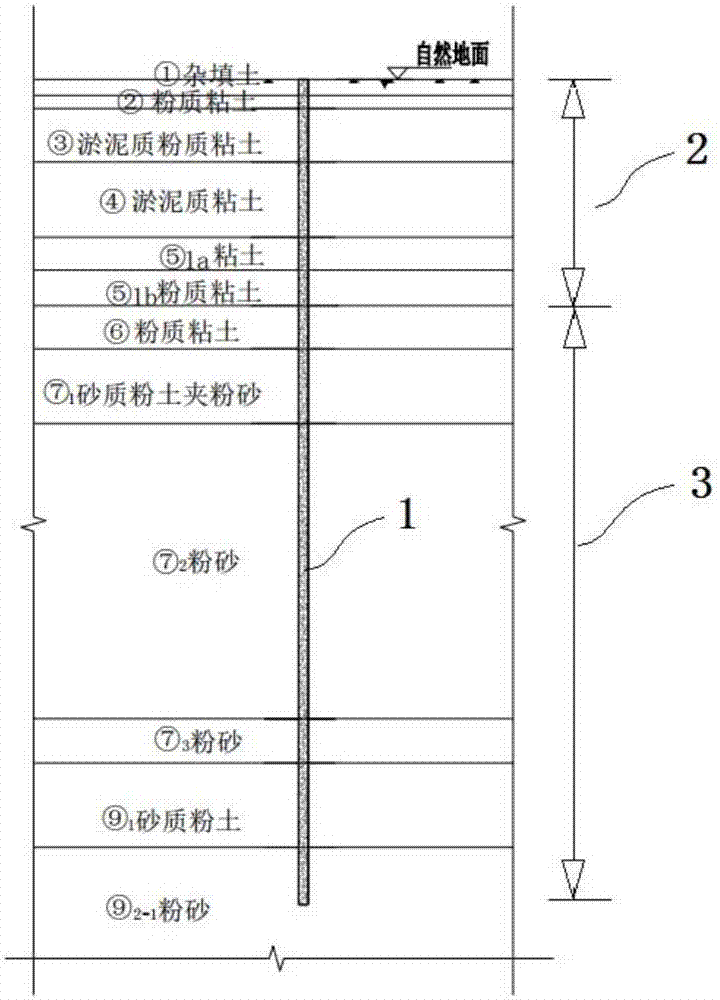

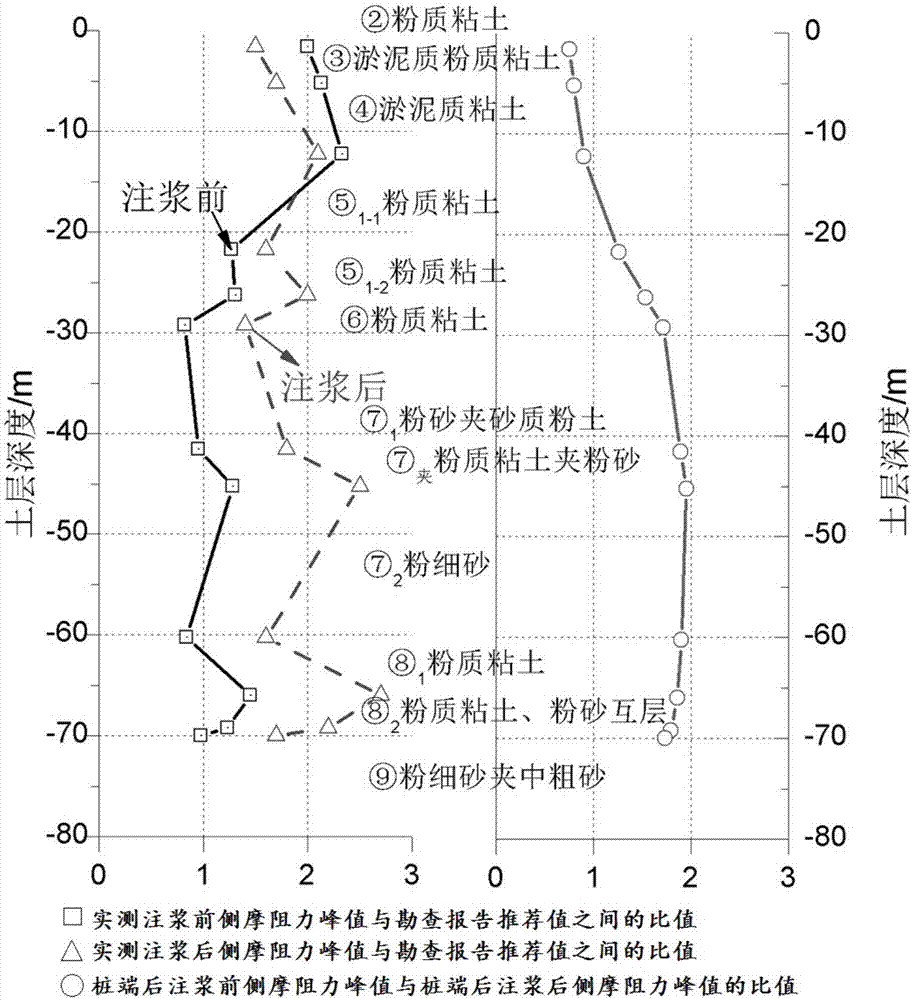

[0046] Such as figure 1 As shown, the total length of the ultra-long pile 1 of a project in Shanghai Hongqiao is 70m, the effective pile length is calculated from the ground, the effective length L=70m, the pile diameter D=0.85m, and the bearing layer at the pile end is the ninth layer of fine sand Coarse sand in the middle, the comparison of bearing capacity before and after grouting at the pile tip image 3 and shown in Table 1 below.

[0047] Table 1: Comparison of pile tip resistance before and after post grouting of ultra-long piles in Example 2

[0048]

[0049] From image 3 And Table 1 shows:

[0050] (1) Non-direct reinforcement section 2 without grout upward return: the scope is the silty c...

Embodiment 3

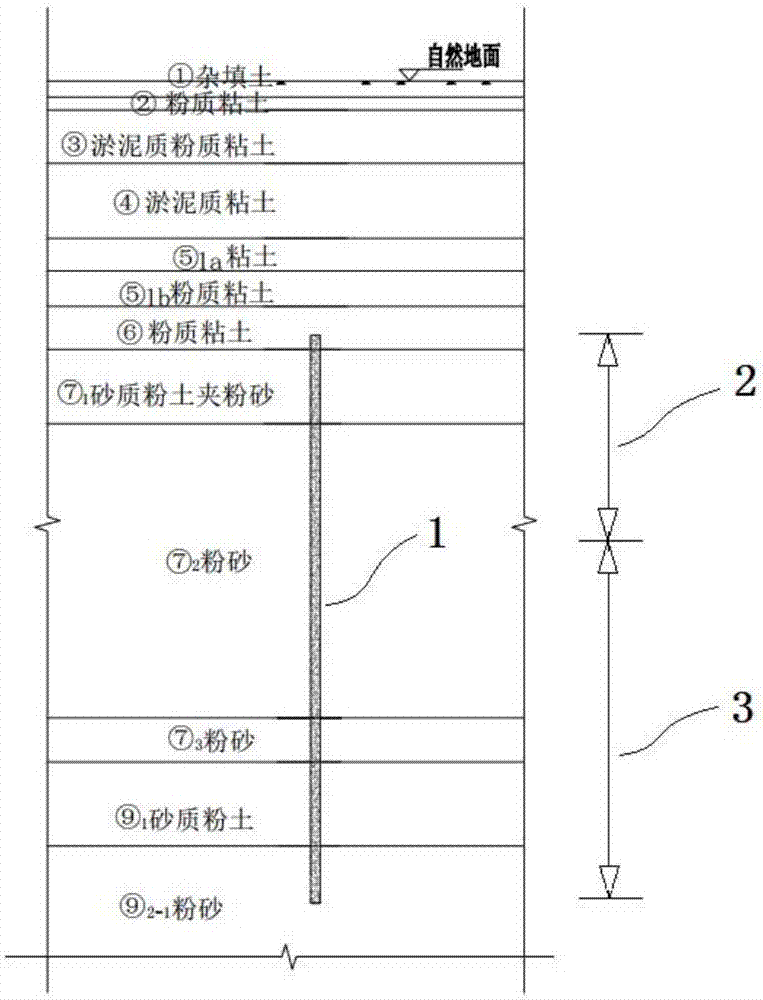

[0054] [Example 3] On the basis of Example 1, this example combines a specific engineering case (the C1882 super-long pile of a certain project in Shanghai Hongqiao) to estimate the ultimate bearing capacity of the post-grouting super-long pile at the pile end. Specific instructions:

[0055] The pile length of the C1882 ultra-long pile in a project in Shanghai Hongqiao is 50m. The effective pile length is calculated from the ground. Comparison of bearing capacity before and after slurry Figure 4 And as shown in Table 2 below.

[0056] Table 2: Comparison of pile tip resistance before and after post grouting of ultra-long piles in Example 3

[0057]

[0058] From Figure 4 And Table 2 shows:

[0059] (1) Non-direct reinforcement section 2 without grout upward return: the scope is the silty clay layer of ⑤1b and above with a buried depth of more than 22m, mainly silty clay and silty clay, and the length is about 2 / 5L. After grouting, the side friction resistance increa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com