Auxiliary platform for small-size transformer of urban distribution network

A technology for auxiliary platforms and transformers, applied in hoisting devices, electrical components, switchgear, etc., can solve the problems of transformer heat dissipation system or bushing damage, low work efficiency, and large limitations, and achieve flexible and changeable construction methods. The effect of convenient hanging of parts and convenient inspection and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

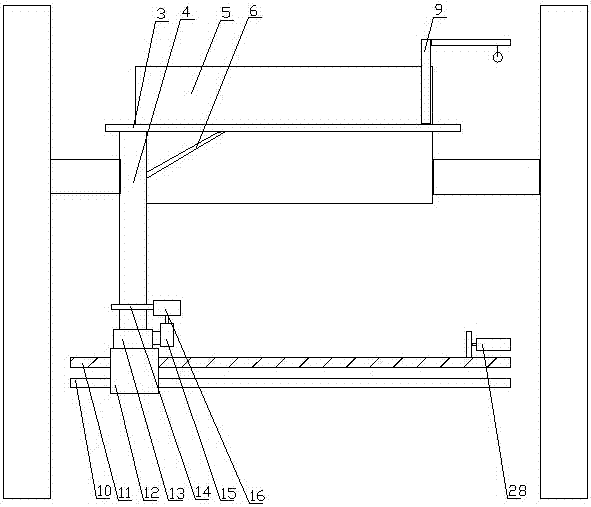

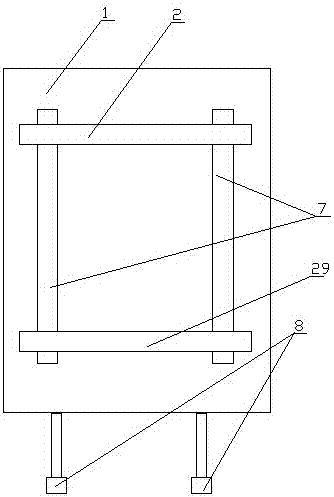

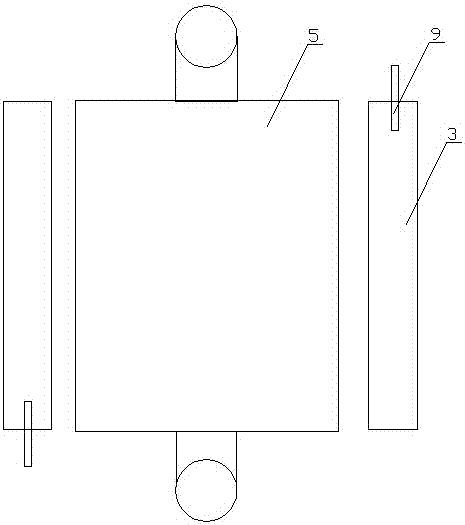

[0033] like Figure 1 to Figure 5As shown: this embodiment provides a small transformer auxiliary platform for urban distribution network, including a car body 1, a sliding track 7 set on the car body 1, and a first translation mechanism 2 parallel to each other is set on the sliding track 7 and the second translation mechanism 29, the first translation mechanism 2 and the second translation mechanism 29 are provided with a lifting mechanism, the top of the lifting mechanism is provided with an inspection platform 3, and the front end of the inspection platform 3 is movable to set an L-shaped hanger 9, The rear end of the vehicle body 1 is provided with an L-shaped bracket 8 .

[0034] The inspection platform is rotated and set on the top of the lifting mechanism, and the inspection platform is telescopically set, so that when inspecting any part of any side of the transformer, by rotating the direction of the inspection platform and adjusting the translation mechanism, the L-...

Embodiment 2

[0038] like Image 6 Shown: its difference with embodiment one is:

[0039] The L-shaped hanger 9 is movably arranged on the front end of the second bottom plate 17, and the front end of the second cross arm 18 is movably provided with a docking mechanism; Pipes 23, a third bottom plate 22 is arranged between the fixed pipes 23; a rotating base 26 is arranged at the front end of the second bottom plate 17, and a fixed socket 27 is arranged on the rotating base 26 corresponding to the L-shaped hanger 9 .

[0040] The maintenance platform is set on the two sides corresponding to the transformer through the first translation mechanism and the second translation mechanism, and the docking mechanism is movable at the front end of the second cross arm, so that the height of the maintenance platform is higher than that of the transformer, and the front ends of the two maintenance platforms can be rotated after rotation. Butt together, so as to build a hanging and maintenance platfo...

Embodiment 3

[0042] like figure 1 Shown: its difference with embodiment one is:

[0043] The lifting mechanism includes a hydraulic lifting column 4 and a supporting base 13 that is rotatably connected to the lower end of the hydraulic lifting column 4. A drive motor 15 is arranged on the supporting base 13, and an annular rack 14 is arranged at the bottom of the hydraulic lifting column 4. The driving motor 15 is connected to the ring rack 14 through a reduction box 16 in transmission.

[0044] The translation mechanism includes a lead screw 11, a translation motor 28 for driving the lead screw 11 and a fixed rod 10 matched with the lead screw 11, and a slider 12 is sleeved on the lead screw 11 and the fixed rod 10, so that The support base 13 is provided on the slider 12; the outer surface of the screw 11 and the fixed rod 10 is provided with a graphite lubricating layer.

[0045] The lifting mechanism adopts a hydraulic lifting column, which has stronger lifting strength and better st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com