Stamping auxiliary device capable of machining high-precision protrusion part

A high-precision, auxiliary technology, applied in the field of sheet metal parts processing, can solve problems such as inability to ensure high precision, and achieve the effect of not being easily deformed and ensuring stamping accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

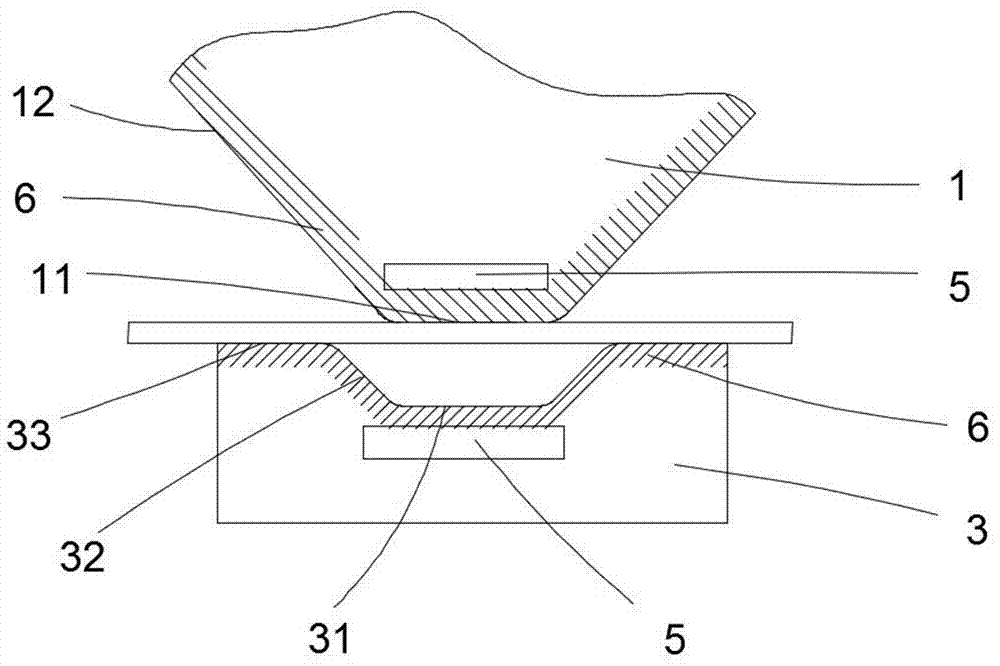

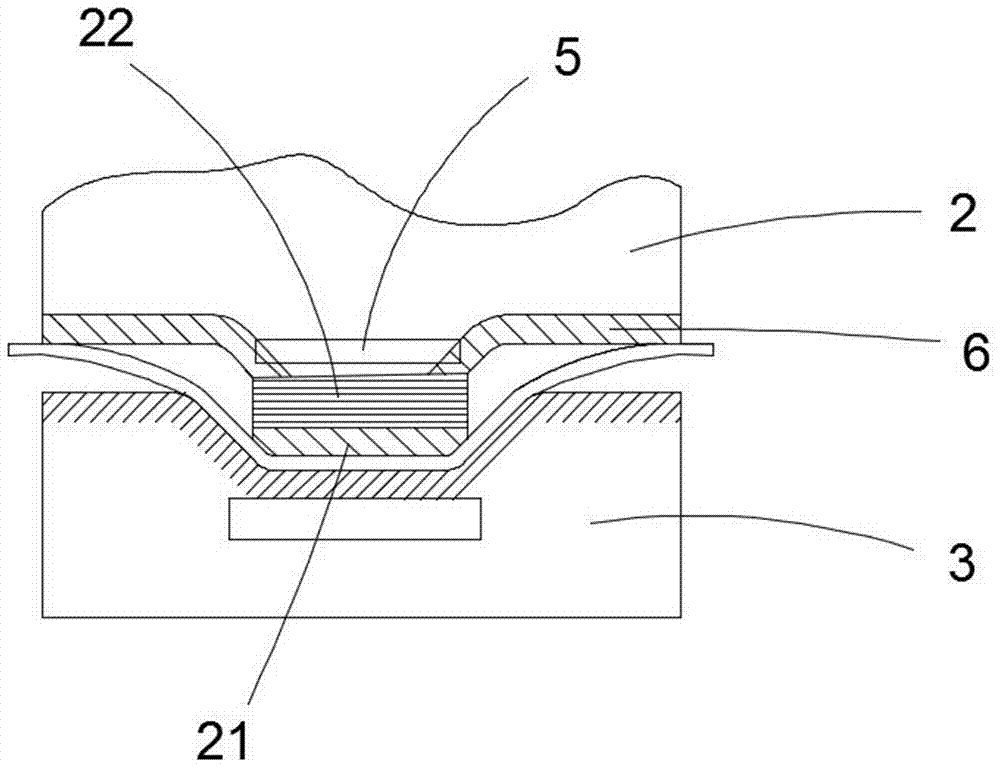

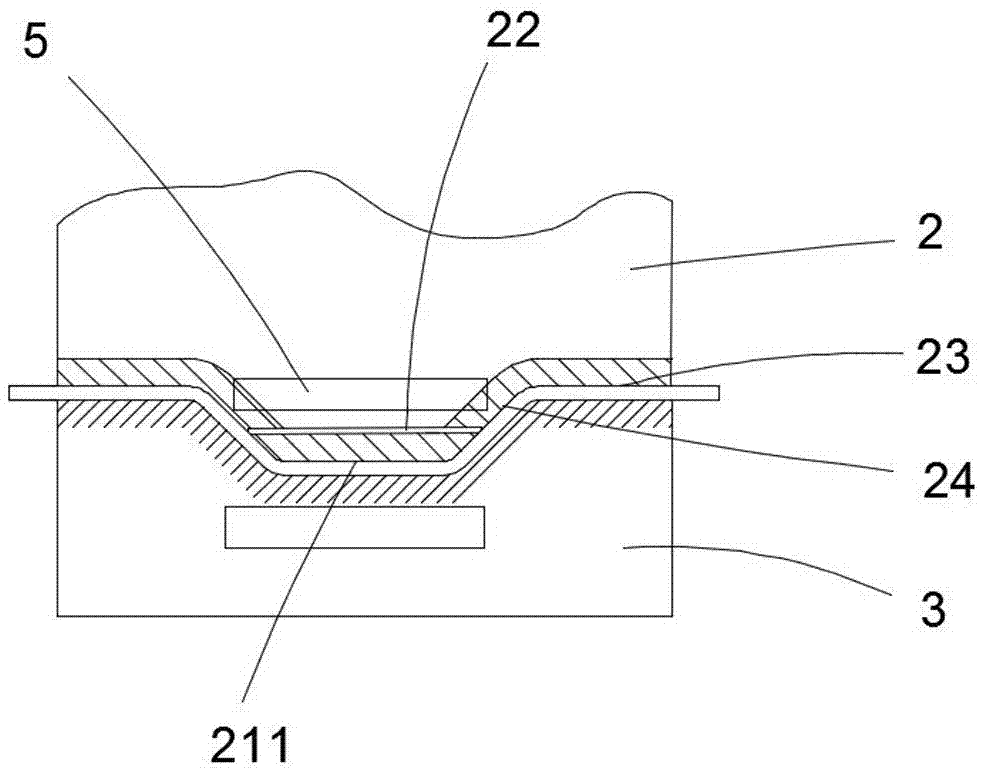

[0023] The invention discloses a stamping auxiliary tool for processing high-precision convex parts, such as Figure 1 to Figure 4 As shown, it includes a first stamping die 1, a second stamping die 2 and an auxiliary tool 3. The auxiliary tool 3 is provided with a concave part adapted to the shape of the workpiece convex part 4, and the end of the first stamping die 1 is in contact with the workpiece convex part. The shape of the end of the second stamping die 2 is adapted to the shape of the end, and the end of the second stamping die 2 is provided with a retractable briquetting block 21. After the briquetting block 21 is shortened, the overall shape of the second stamping die 2 is adapted to the shape of the convex part 4 of the workpiece; The first stamping die 1 , the second stamping die 2 and the auxiliary tool 3 are all provided with a heating device 5 .

[0024] In this embodiment, the recessed portion includes a bottom surface 31, a slope 32 and a surface 33; a rounde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com