Semi-automatic solar module border remover

A technology for solar modules and dismantling machines, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of high work intensity of employees and damage to battery sheets, so as to reduce labor costs, improve work efficiency, and protect solar cells board effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

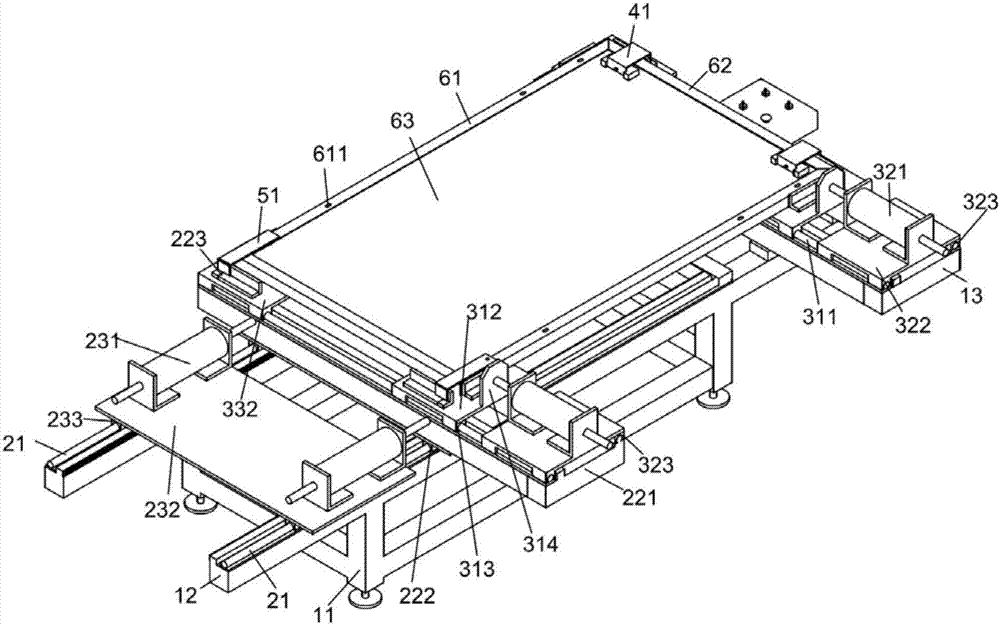

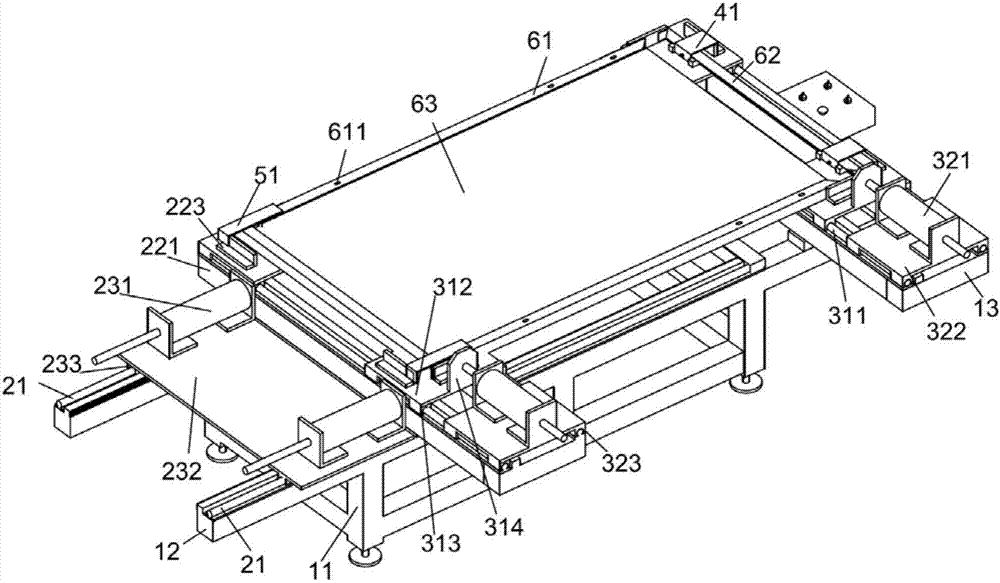

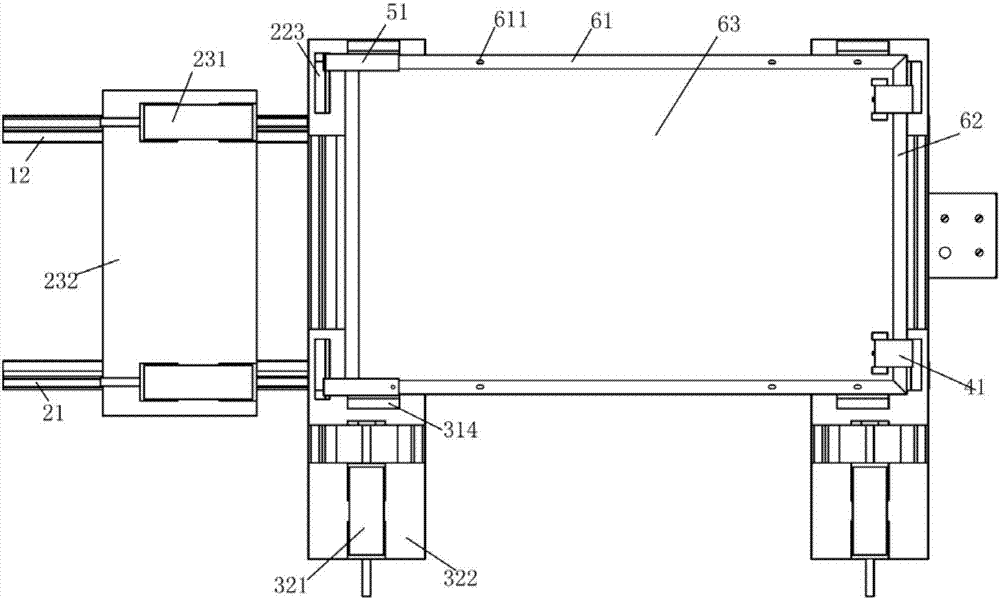

[0031] A semi-automatic solar module frame removal machine, such as Figure 1~5 As shown, it includes two fixing frames 12, and the two fixing frames 12 are sequentially provided with a fixing plate 13, a component placement platform and a longitudinal sliding device, and a solar module is placed on the module placement platform, and the solar module includes solar energy The battery panel 63 and the short frame 62 and the long frame 61 that cover the four sides of the solar cell panel 63, the fixing plate 13 is provided with a clamp 41 that can be clamped at the corner of the short frame 62 and a longitudinal baffle 223 that can position the solar module ;

[0032] The longitudinal sliding device includes a longitudinal sliding bar 21 arranged above the fixed frame 12, and the longitudinal sliding bar 21 is provided with a longitudinal sliding mechanism capable of longitudinally sliding, and the longitudinal sliding mechanism includes a vertical sliding mechanism arranged on ...

specific Embodiment approach

[0038] The first step: place the solar module on the module placement table;

[0039] Step 2: Clamp the fixture 41 on the short frame 62 of the solar module, and at the same time clamp the fixture 41 on the longitudinal baffle 223 to make it stable, as figure 1 or figure 2 shown;

[0040] The third step: embed the puller tool 51 on the long frame 61 of the solar module, and at the same time, the puller tool 51 also clamps the longitudinal baffle 223 to make it stable, such as figure 1 or figure 2 shown;

[0041] Step 3: activate the longitudinal cylinder 231, slide the longitudinal cylinder 231 outward, remove a short frame 62, and return the cylinder to its original position;

[0042] Step 4: Reverse the solar module, and repeat the installation of clamp 41 and puller 51;

[0043] Step 5: start the longitudinal cylinder 231, slide the longitudinal cylinder 231 outside, remove the other short frame 62, and return the cylinder to its original position;

[0044] Step 6: ...

Embodiment 2

[0047] This embodiment is further optimized on the basis of the above embodiments, such as Figure 1~5 As shown, the longitudinal sliding plate 221 and the fixed plate 13 are provided with a horizontal baffle 314 capable of positioning solar modules; the bottom of the longitudinal sliding plate 221 is provided with a longitudinal sliding groove a222 matching the longitudinal sliding bar 21; The longitudinal transmission mechanism also includes a longitudinal installation plate 232 for installing the longitudinal cylinder 231 , and the bottom of the longitudinal installation plate 232 is provided with a longitudinal sliding groove b233 capable of matching with the longitudinal sliding rod 21 .

[0048] The specific implementation mode of increasing the above-mentioned technical features: in order to make the lateral positioning of the device more accurate during the dismantling process, a lateral baffle 314 is adopted, and the fixed plate 13 and the longitudinal sliding plate 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com