Novel two-freedom-degree parallel-connection robot imitating elbow joint of human being

An elbow joint and degree of freedom technology, which is applied in the field of new two-degree-of-freedom parallel robots, can solve problems such as difficulties in the popularization and application of parallel robots, high cost of parts processing, and complexity of motion control, etc., to achieve favorable promotion, low cost, and easy promotion popular effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

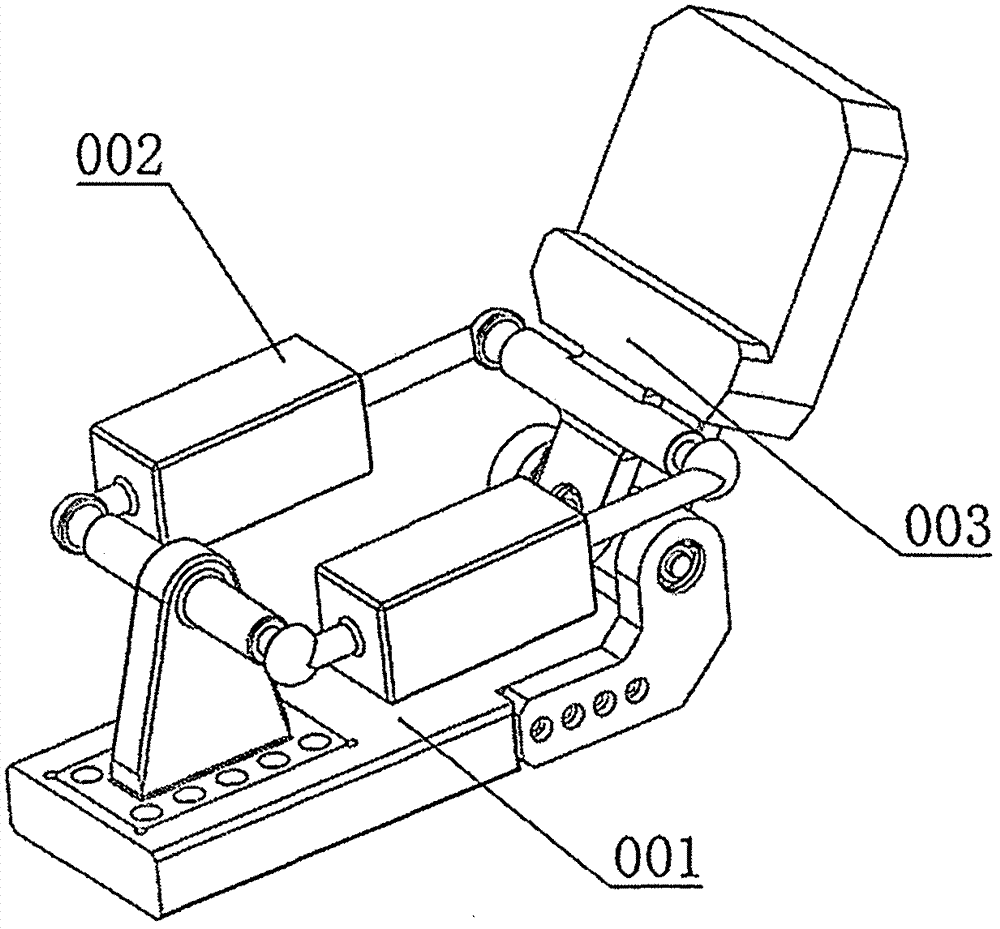

[0015] Such as figure 1 As shown, a new two-degree-of-freedom parallel robot that mimics the human elbow joint includes: a base 001, an electric push rod assembly 002, and a working platform 003. It is characterized in that: the base 001 is used for the installation of various mechanisms, and the two sets of electric push rod assemblies 002 connect the base 001 and the working platform 003 in parallel through ball hinges at both ends.

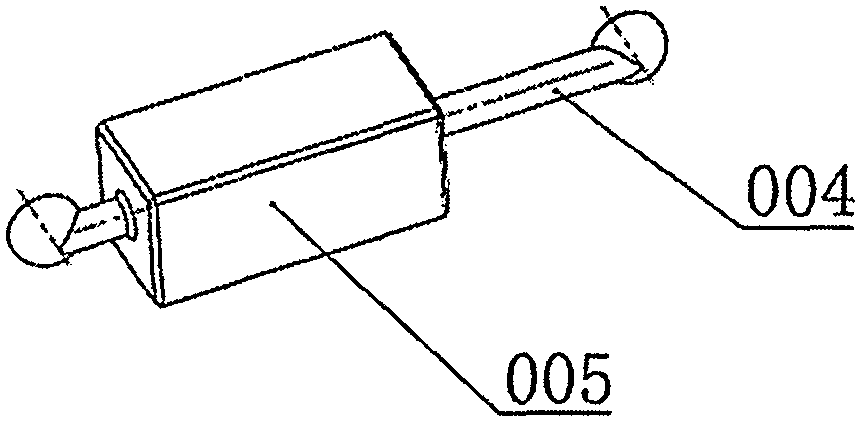

[0016] Such as figure 2 As shown in the electric push rod assembly, the motor 005 is connected to the push rod 004. Through the control of the motor 005, the push rod 004 can be pushed to perform telescopic movement. The spherical hinges at the ends of the motor 005 and the push rod 004 are respectively connected to the base 001 Connect with working platform 003.

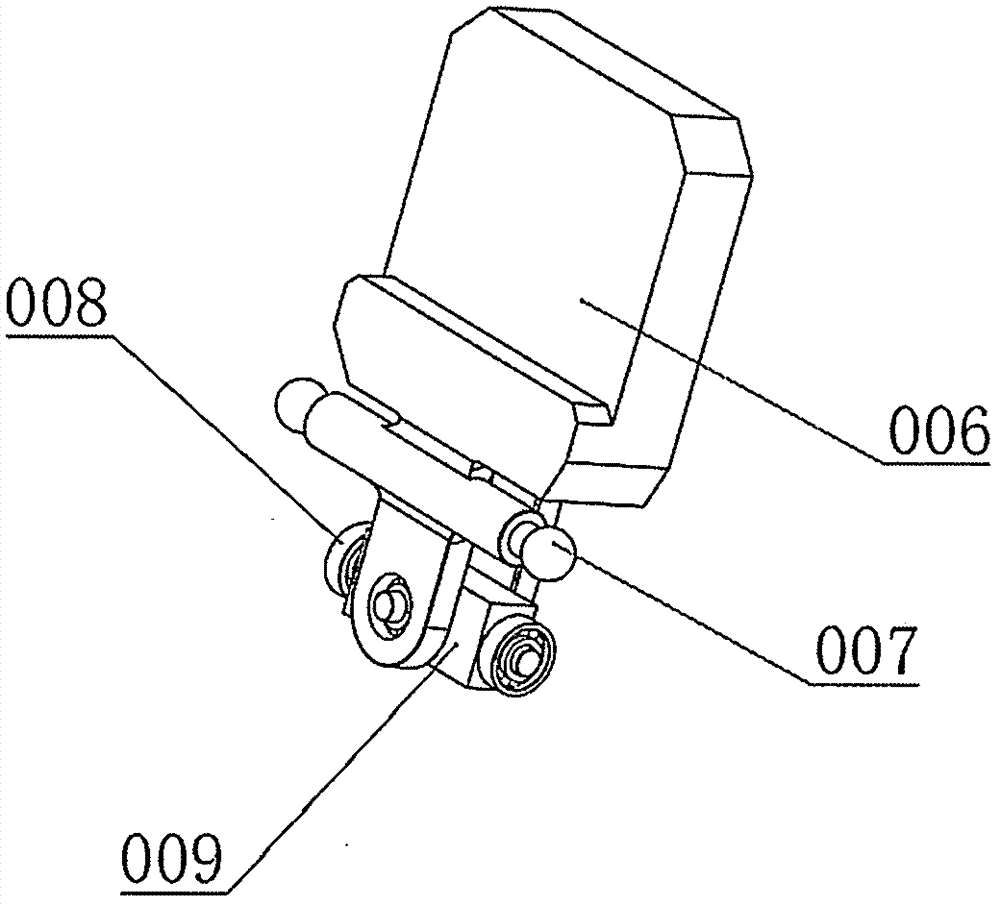

[0017] Such as image 3 As shown, the working platform 003 includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com