Horizontal feeding suspension type shifting mechanism of in-mold labeling withdrawing device

A technology of removing device and in-mold labeling, applied in coating and other directions, can solve the problems of increasing production cost, complicating mechanism and control system, etc., and achieve the effect of reducing production cost, simplifying mechanism and system, and small buffer resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

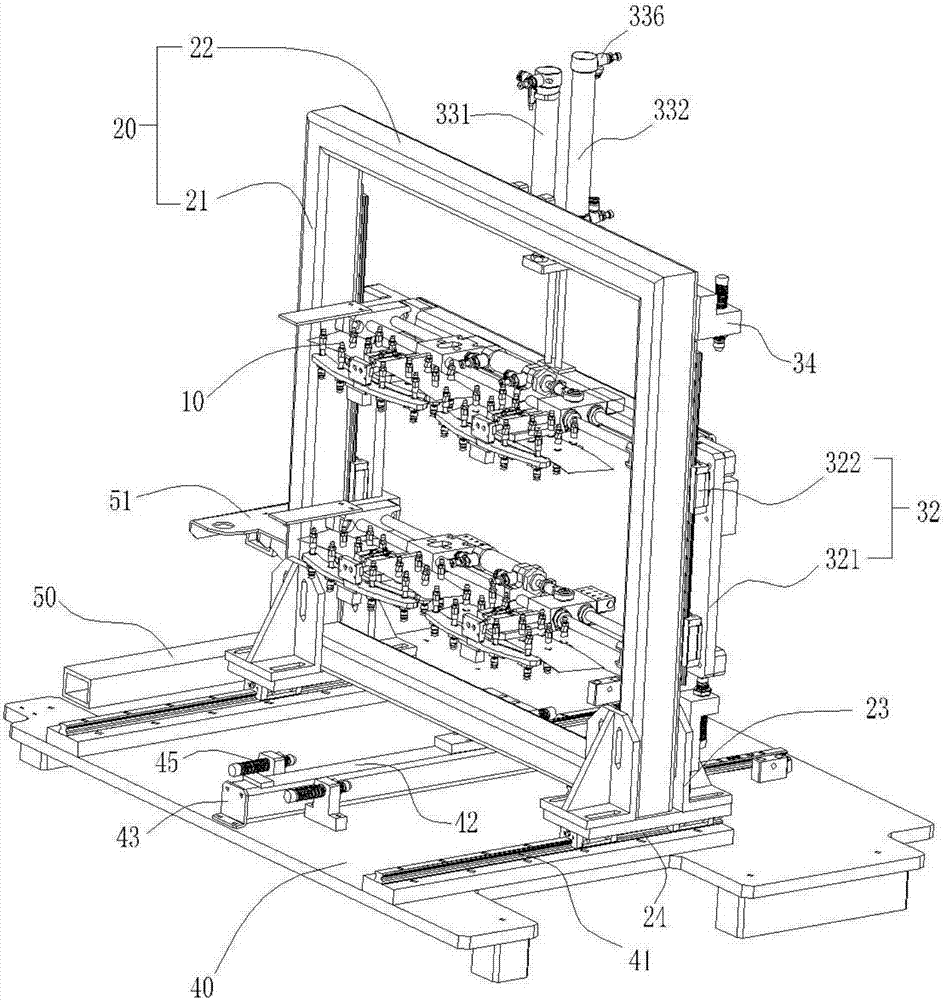

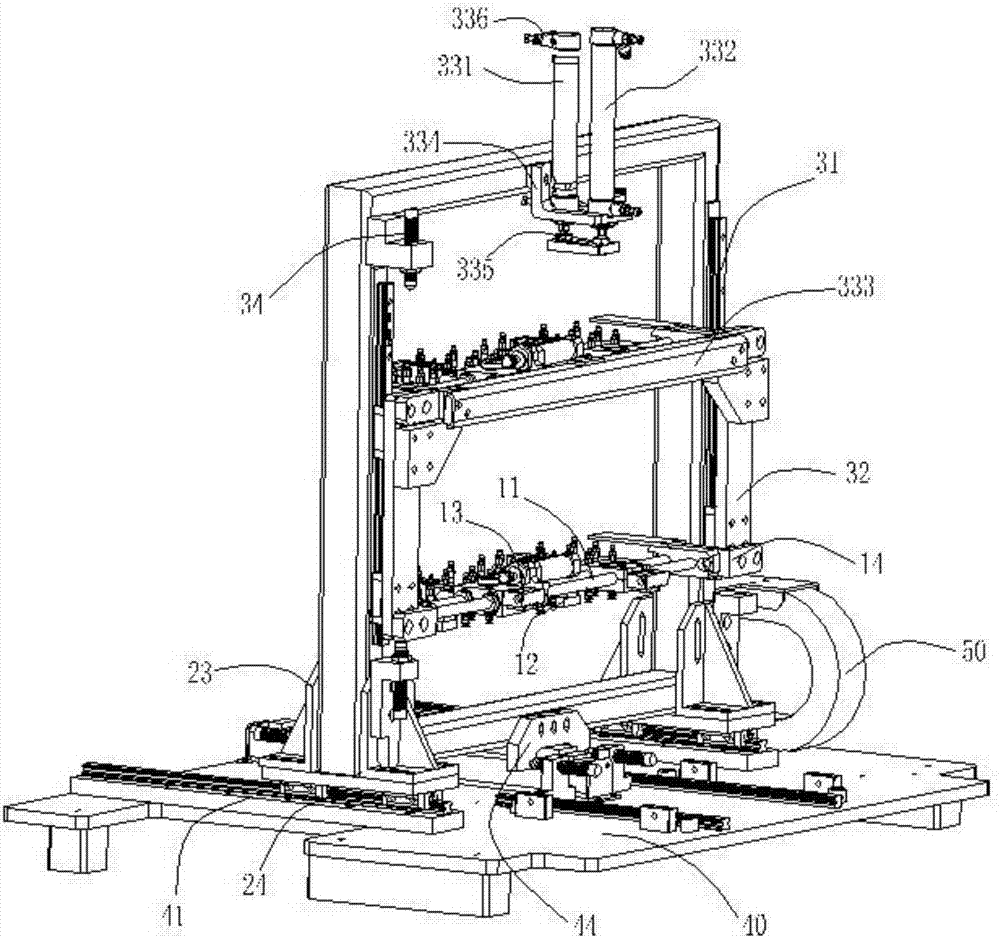

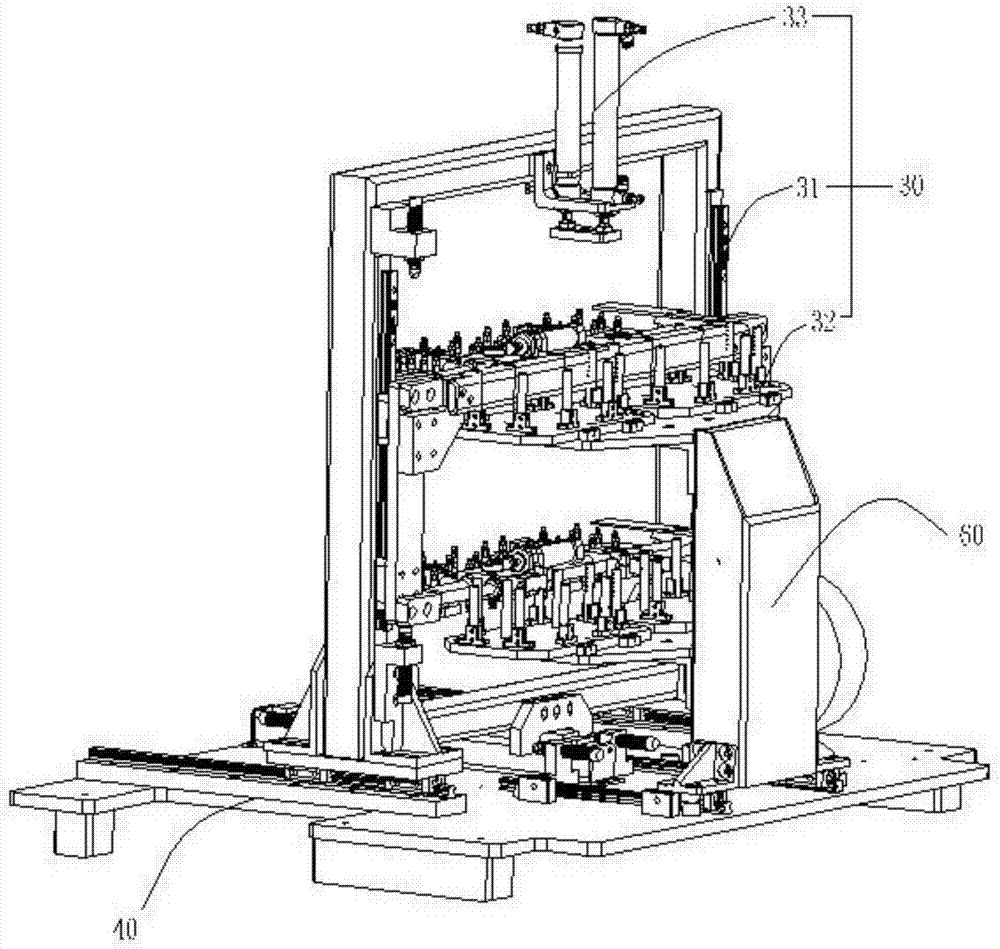

[0025] like figure 1 , figure 2 , image 3 As shown, the horizontal feeding suspension shift mechanism of the in-mold labeling take-out device of the present invention is used to transport the labels in the label chamber to the jig that needs to be labeled, including a label taking device and a label delivery device; The label-taking device comprises a label-taking component 10 for label-taking, a square fixed frame 20 for fixing the label-taking component 10, a suspension lifting device 30 for enabling the label-taking component 10 to be suspended and lifted; the suspended lifting device 30 The device includes a vertical slide rail 31 arranged on two vertical beams 21 of the square fixed frame 20, a slide assembly 32 slidably connected on the vertical slide rail 31, and a drive that drives the slide assembly 32 to move up and down along the vertical slide rail 31. device 33, the driving device 33 includes a stroke cylinder 331 and a gravity cylinder 332 that maintains the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com