Double disc type overpressure control valve

A technology for controlling valves and valve discs, applied to valve details, safety valves, balance valves, etc., can solve problems such as weak resistance to impact, deterioration of the workpiece environment, and howling noise, to achieve impact resistance, noise reduction, and damage reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

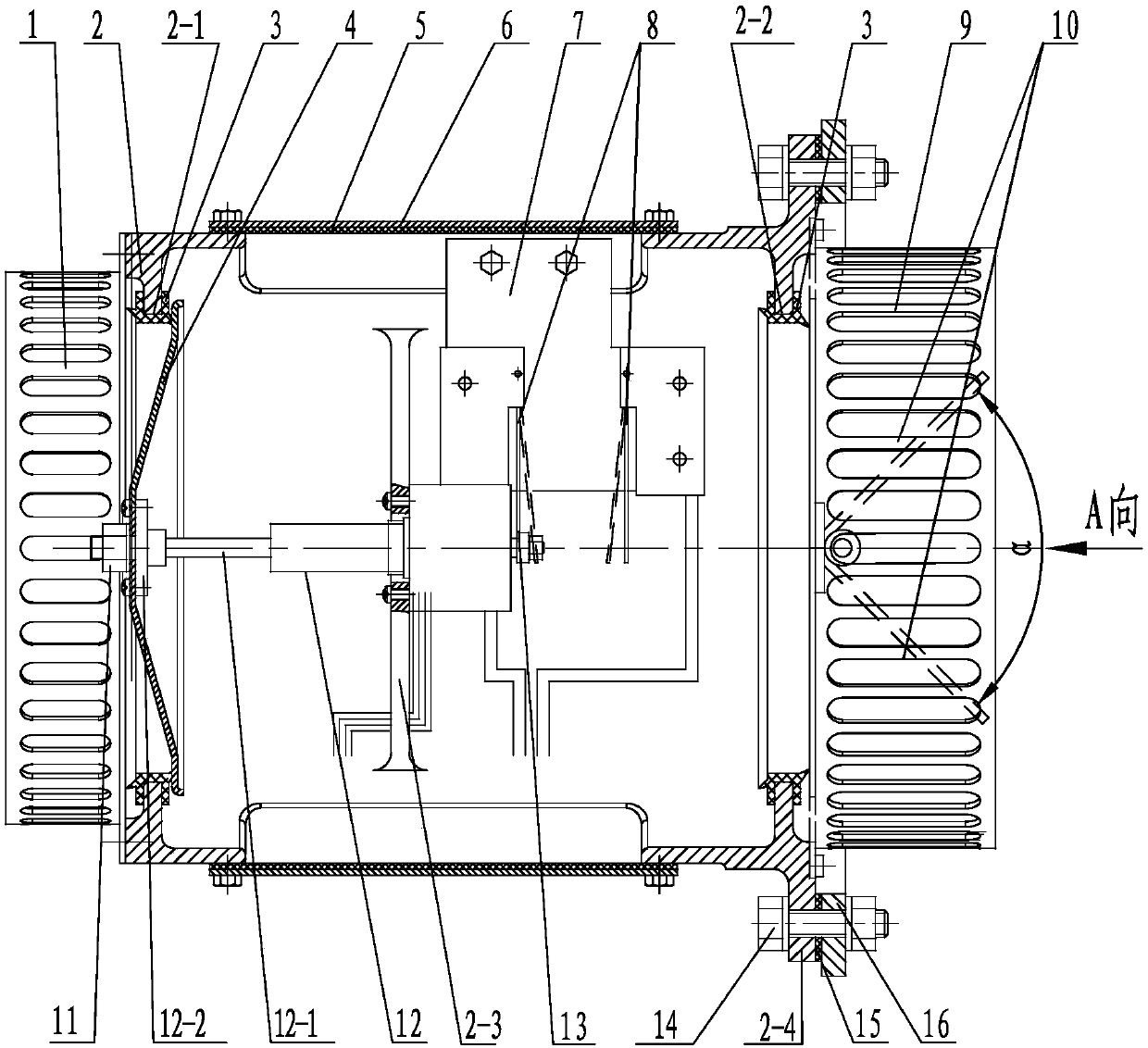

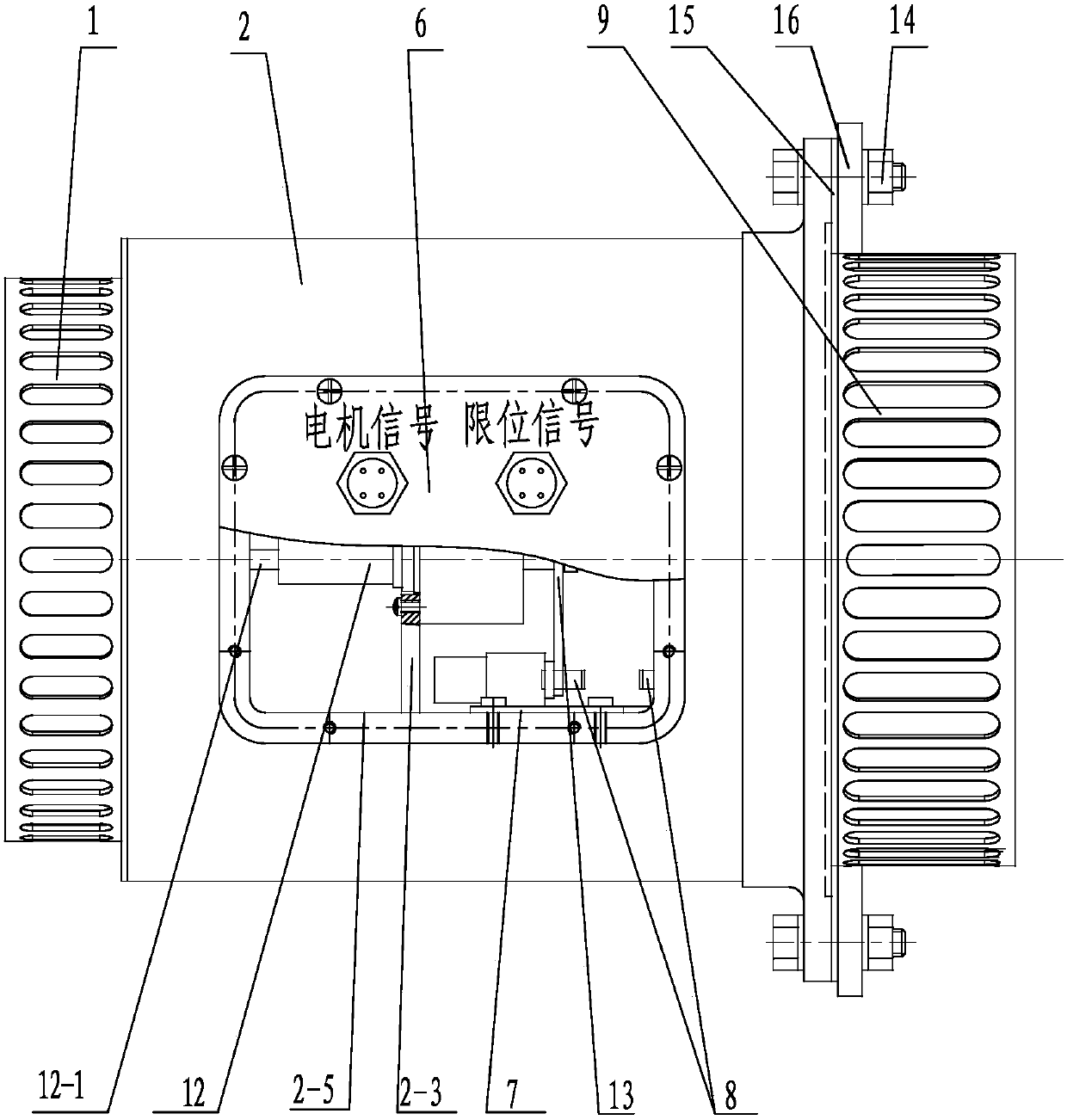

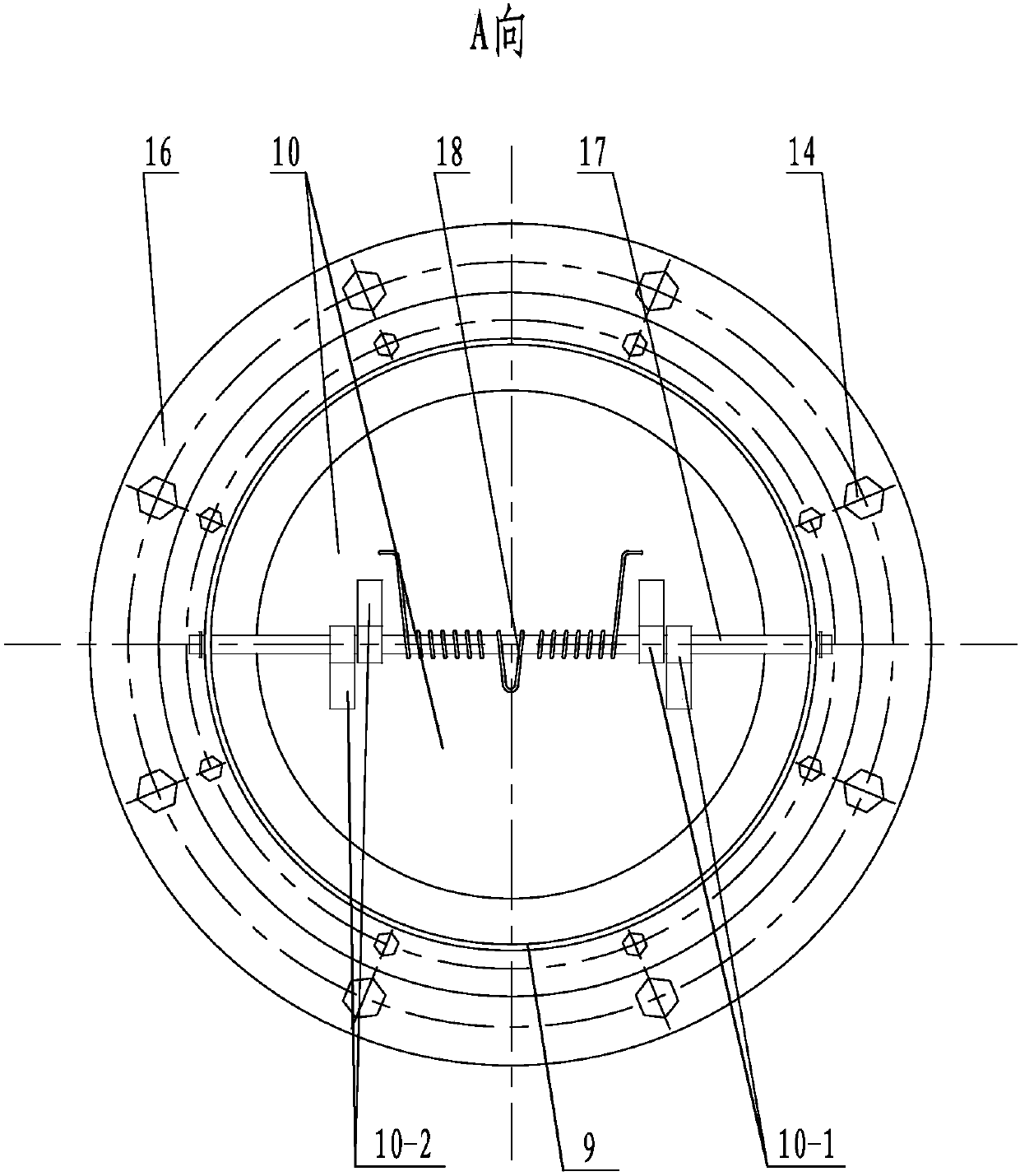

[0019] The double-valve disc overpressure control valve of the present invention includes a main valve and a controller. See Figure 1~3 As shown, the main valve of the present invention includes a valve body 2 , a front valve disc 4 arranged at the front of the valve body 2 , an anti-shock disc assembly at the rear and a stepping motor 12 inside the valve body 2 . See figure 1 , 2 As shown, the front side of the valve body 2 of the present invention is provided with a front valve port 2-1, and the rear side is provided with a rear valve port 2-2, and the sealing ring 3 is wrapped on the front valve port 2-1 and the rear valve port 2-2. , The front part of the valve body 2 is equipped with a front protective net cover 1, which can prevent large foreign matter from entering the valve body 2. See figure 1 As shown, the rear side of the sealing ring 3 of the present invention has a lip, and the current valve disc 4 is pressed on the lip of the sealing ring 3 of the front valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com