Platform tray structure used for bus passenger door system

A passenger door, platform technology, applied in the direction of doors, motor vehicles, vehicle parts, etc., can solve the problems of poor commonality of parts, no expansion interface, high requirements for manpower and capital investment, etc., to reduce enterprise investment costs and optimize space. The effect of layout and shortening the development cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

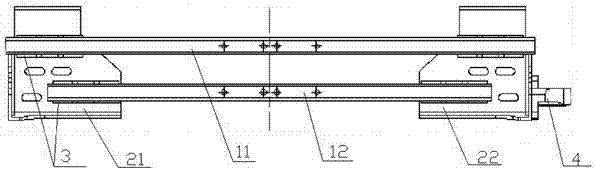

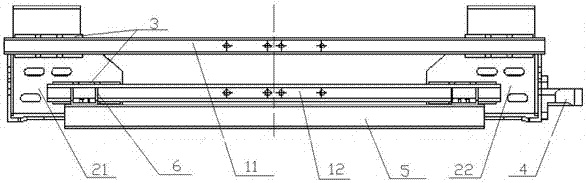

[0030] like figure 1 As shown, a platform pallet structure for passenger car passenger door system, the pallet structure includes a left pallet holder 21, a right pallet holder 22 and an upper beam 11 and a lower beam 12 of the same width, the upper and lower beams are two The ends are respectively connected with one side plate of the left and right pallet holders through the beam bracket 3 , and the other side plate of the right pallet holder 22 is provided with a door shaft fixing seat 4 . The cross-beam section is U-shaped or Ω-shaped, and one end of the cross-section opening is connected to the cross-beam bracket 3 .

Embodiment 2

[0032] The difference between this embodiment and Embodiment 1 is that the upper and lower beams are provided with pipeline installation interfaces.

[0033] The tray structure described in Embodiment 1-2 is suitable for a single-leaf swing out passenger door.

Embodiment 3

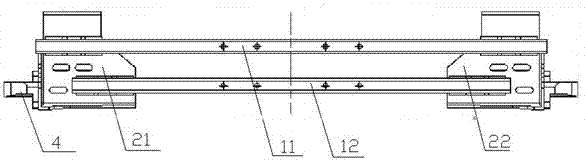

[0035] like figure 2 As shown, a platform pallet structure for passenger car passenger door system, the pallet structure includes a left pallet holder 21, a right pallet holder 22 and an upper beam 11 and a lower beam 12 of the same width, the upper and lower beams are two The ends are respectively connected with one side plate of the left and right pallet holders through the beam bracket, and the other side plates of the left and right pallet holders are respectively provided with door shaft fixing seats 4 . The cross-beam section is U-shaped or Ω-shaped, and one end of the cross-section opening is connected to the cross-beam bracket.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com