Staggered-truss steel structure system with uniform stiffness

A steel structure and truss technology, applied in the field of staggered truss steel structure system, can solve the problems of normal use of buildings affecting structural safety, large torsional displacement of structures, and difficulty in implementation, etc., to achieve beautiful appearance, reduce torsional effect, and comfort Enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

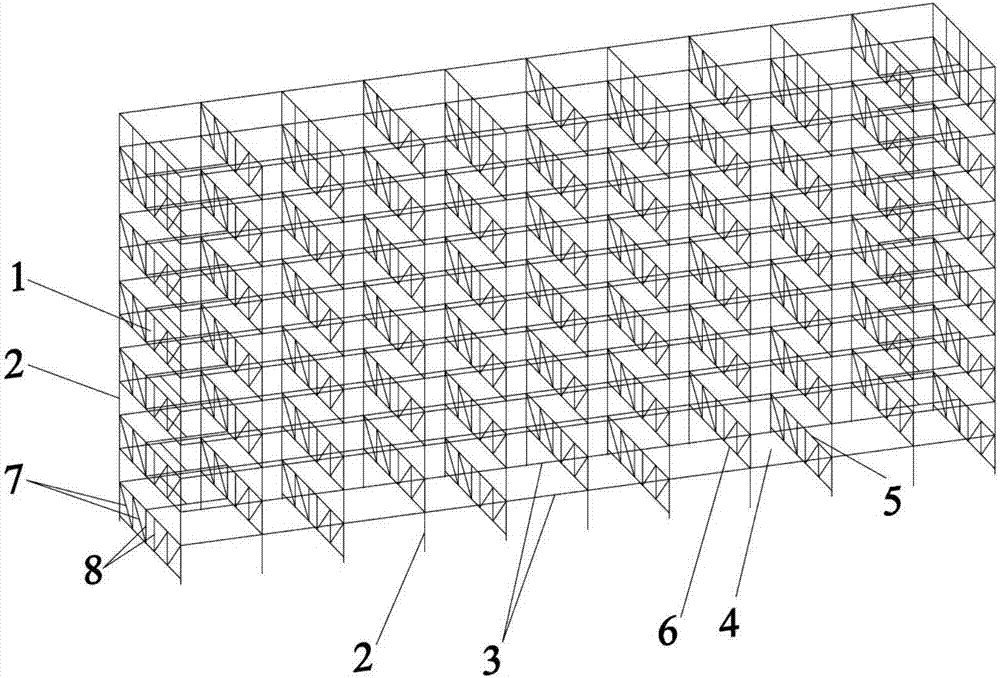

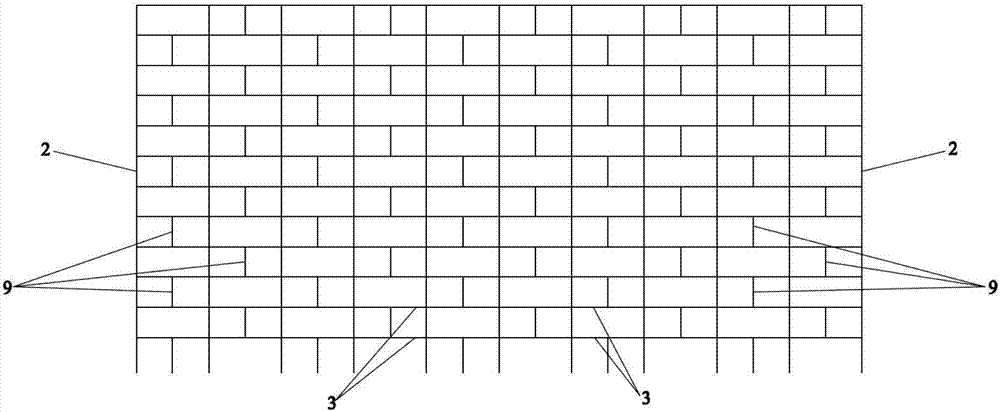

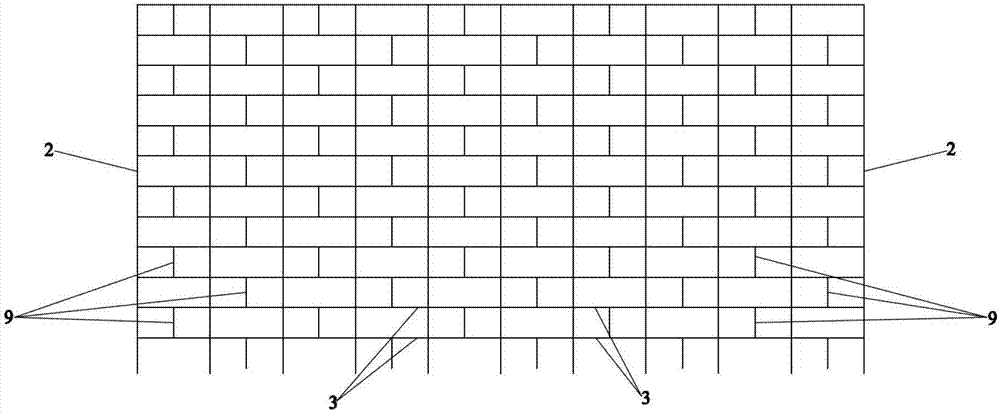

[0023] See figure 1 , The preferred embodiment of the present invention will be further described.

[0024] A staggered truss steel structure system with balanced stiffness. The main improvement of the present invention is to add a column 9 to the staggered truss steel structure system. The column 9 is arranged in the middle of the longitudinal frame beam 3 with interlayers and spans in the longitudinal direction. To make up for the lack of longitudinal stiffness in the entire structural system.

[0025] The staggered truss steel structure system mainly includes trusses 1, frame columns 2, and longitudinal frame beams 3. The truss 1 is arranged horizontally along the structure, and the frame beam 3 is arranged longitudinally along the structure.

[0026] The height of the truss 1 is the same as the height of a single house in the structural system, and the length is the same as the width of a single house. Both ends of the truss 1 are supported on the frame columns 2, and the truss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com