A three-layer composite floor and its manufacturing method

A manufacturing method and layer compounding technology, applied in the direction of manufacturing tools, wood layered products, chemical instruments and methods, etc., can solve the problems of surface plate thickness rebound, achieve flatness maintenance, maintain surface flatness and dimensional stability, The effect of high surface flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

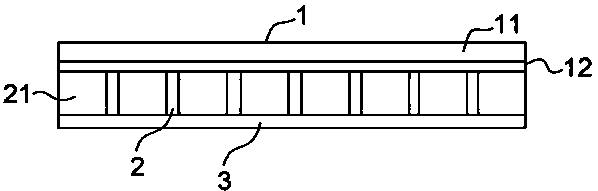

[0027] Example: such as figure 1 A three-layer composite floor is shown, which includes a surface board 1, a core board 2 and a bottom board 3 from top to bottom; the top board 1 includes at least a high-density layer 11 and a transition layer 12 from top to bottom, and the high-density layer 11 The average density on its thickness section is 0.65-0.75g / cm 3 The density of the transition layer 12 on its thickness section gradually decreases from the side close to the high-density layer 11 to the side close to the core plate 2; the high-density layer 11 and the transition layer 12 are a natural connection of the same material. The maximum density value of the transition layer 12 on its thickness section is 0.45-0.55g / cm 3 ; The minimum density value of the transition layer 12 on its thickness section is 0.40-0.45g / cm 3 . The transition layer 12 and the core board 2 are bonded by glue, and the difference between the density on the side of the transition layer 12 close to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com