A fully automatic tbm excavation device with double hexapod thrusters and double tripod supports

A supporter and thruster technology, applied in mining equipment, tunnels, earthwork drilling and mining, etc., can solve the problems of limited working space, poor environmental adaptability, poor environmental adaptability of support surface or driving surface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

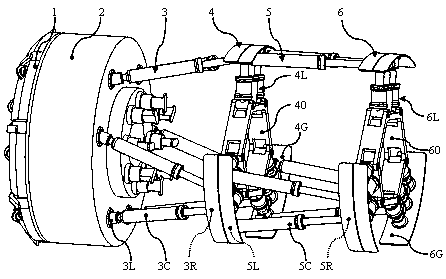

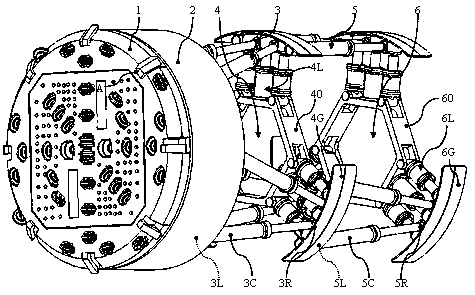

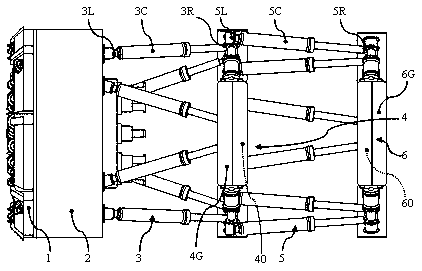

[0111] In this embodiment, a fully automatic TBM excavation device with double hexapod propellers and double three-leg supporters, including a cutter head system 1, a support ring 2, a main propeller 3, a main supporter 4, an auxiliary propeller 5, an auxiliary support 6, such as figure 1 shown.

[0112] The main propeller 3 of the device of this embodiment is a hexapod parallel device, which is composed of 6 main propulsion cylinders 3C. The auxiliary propeller 5 is a hexapod parallel device, which is composed of 6 auxiliary propulsion cylinders 5C; the main supporter 4 is a three-leg parallel device, which is composed of a main central support 40 and three parallel main support legs 4L. 1 main support shoe 4G is housed on each main support leg; The described auxiliary support 6 is a tripod parallel device, which is composed of a sub center support 60 and 3 parallel auxiliary support legs 6L, and each auxiliary support leg is equipped with 1 pair of boots 6G;

[0113] The ...

Embodiment 2

[0198] In this embodiment, a fully automatic TBM excavation device with double hexapod propellers and double three-leg supporters, including a cutter head system 1, a support ring 2, a main propeller 3, a main supporter 4, an auxiliary propeller 5, an auxiliary support 6, such as Figure 8 shown.

[0199] The main propeller 3 of the device of this embodiment is a hexapod parallel device, consisting of 6 groups of hydraulic cylinders, each group of hydraulic cylinders is composed of 2 main propulsion cylinders 3C; the auxiliary propeller 5 is a hexapod parallel device, consisting of 6 The auxiliary propulsion cylinder 5C is composed of; the main supporter 4 is a tripod parallel device, which is composed of a main center support 40 and three parallel main support legs 4L, and each main support leg is equipped with a main support shoe 4G; The secondary supporter 6 described above is a three-legged parallel device, which is composed of a secondary central support 60 and 3 paralle...

Embodiment 3

[0202] In this embodiment, a fully automatic TBM excavation device with double hexapod propellers and double three-leg supporters, including a cutter head system 1, a support ring 2, a main propeller 3, a main supporter 4, an auxiliary propeller 5, an auxiliary support 6, such as Figure 9 shown.

[0203] The main propeller 3 of the device of this embodiment is a hexapod parallel device, which is composed of 6 groups of hydraulic cylinders, and each group of hydraulic cylinders is composed of 2 main propulsion cylinders 3C; the auxiliary propeller 5 is a hexapod parallel device, also composed of 6 groups of hydraulic cylinders. Each group of hydraulic cylinders is composed of two auxiliary propulsion cylinders 5C; the main supporter 4 is a tripod parallel device, which is composed of a main center support 40 and three parallel main support legs 4L. A main support shoe 4G is installed on the support leg; the auxiliary support 6 is a three-legged parallel device, which is compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com