Boost flow centrifugal fan

A centrifugal fan and booster technology, which is applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of insignificant effect and non-soot gas diversion, etc., so as to improve the suction efficiency, improve the flow field, and improve the The effect of suction and discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

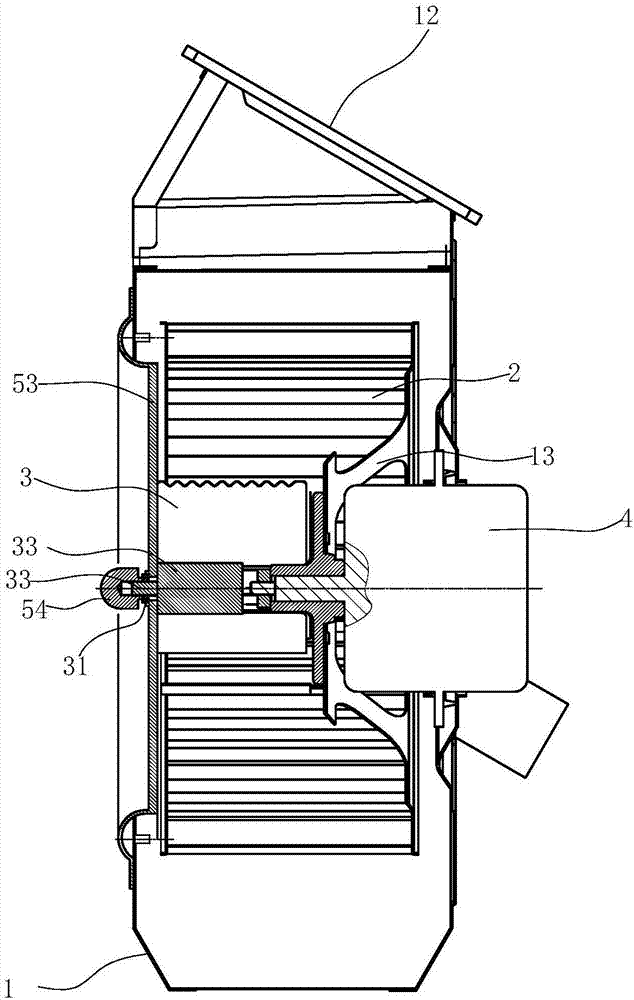

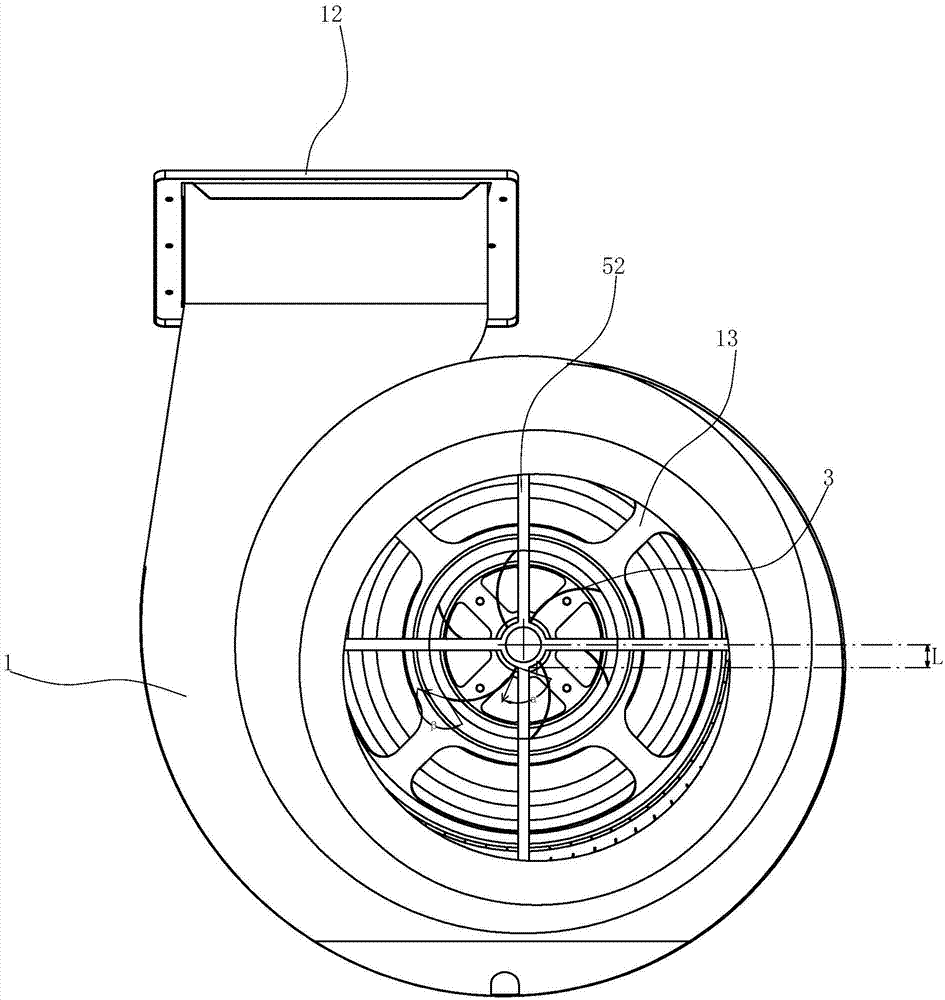

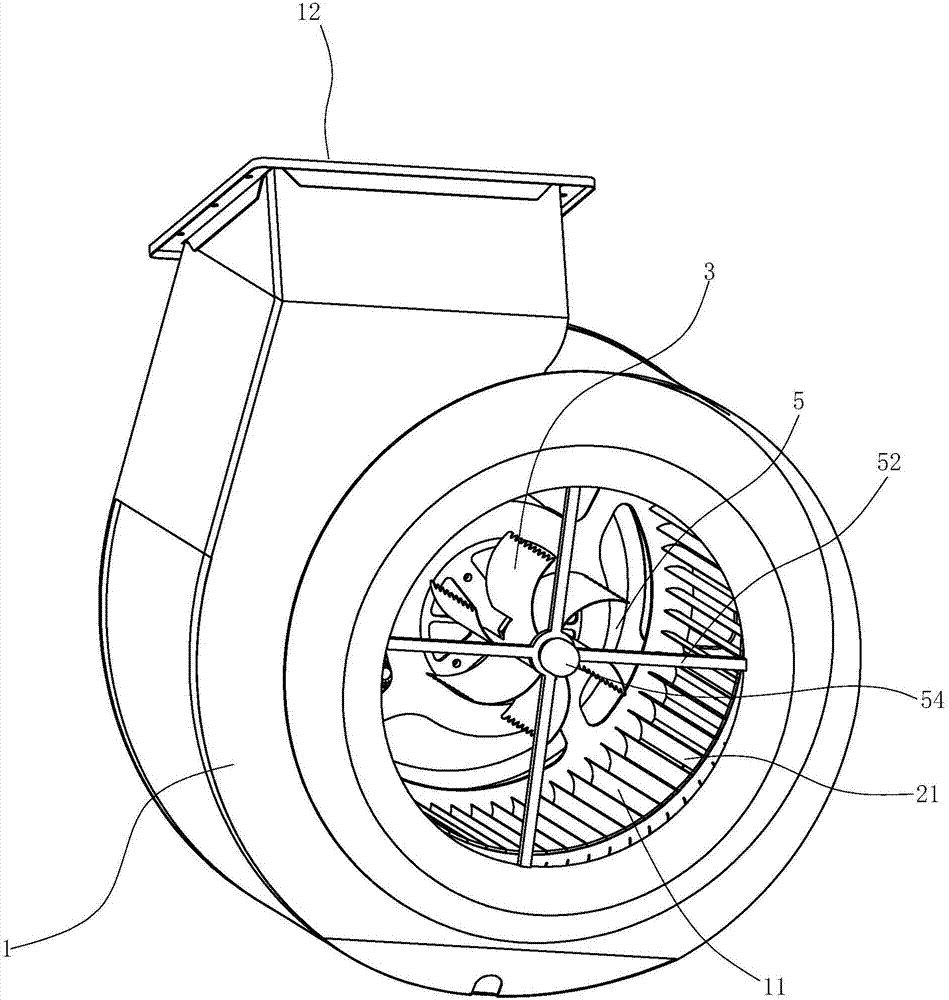

[0028] like Figure 1 to Figure 6 As shown, the multi-blade centrifugal fan includes:

[0029] The volute 1 , the impeller 2 arranged in the volute 1 and the motor 4 driving the impeller 2 to rotate, the volute 1 is provided with an air inlet 11 and an air outlet 12 . The motor 4 is located in the middle of the impeller 2 , and the output shaft of the motor 4 is connected to the impeller 2 through the central plate 13 .

[0030] In the present embodiment, the outer edge of each blade 21 of the impeller 2 is wavy, as Image 6 to improve the noise reduction effect.

[0031] The guide vanes 3 are located on the inner side of the impeller 2 and face the air inlet 11 of the volute 1. There are several pieces, six pieces in this embodiment, which are arc-shaped. On the outer surface, and arranged helically along the periphery of the rotating sha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com