Centrifugation draught fan volute

A technology of centrifugal fan and volute, which is applied in the direction of mechanical equipment, machine/engine, liquid fuel engine, etc. It can solve the problems of uneven flow field at the inlet of volute, affecting the external size of the product, and large left and right dimensions of the volute, so as to achieve improvement User experience, improved fluency, left and right size reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

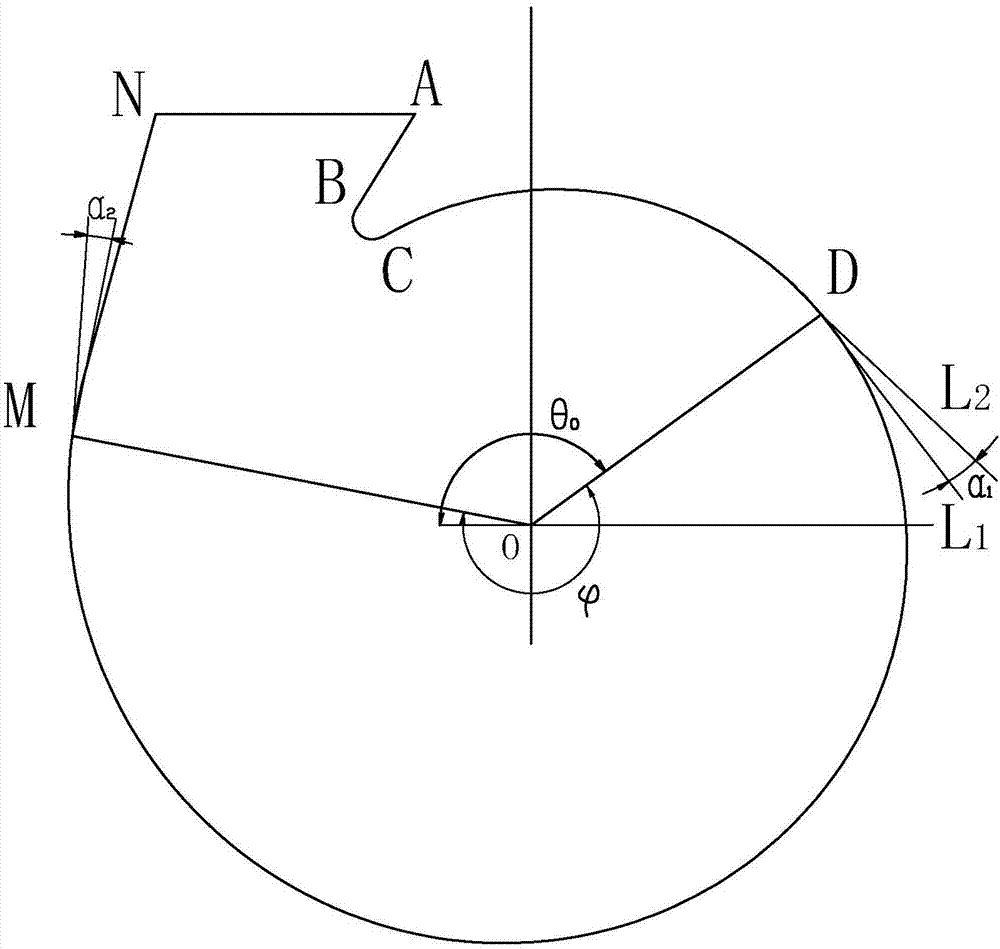

[0012] Such as figure 1 As shown, the volute profile line of the centrifugal fan volute in this embodiment includes a starting line AC located at one end of the profile line and an end line MN located at the other end of the profile line, wherein the starting line AC includes a line adjacent to the fan outlet. The straight line AB and the curve BC corresponding to the volute tongue, the end line MN is adjacent to the air outlet of the fan.

[0013] The volute-shaped line between the start line AC and the end line MN is a helix, and the helix includes a first helix CD connected to the start line AC and a second helix DM connected to the end line MN. The helix CD is an equiangular helix with a constant expansion angle, and the second helix DM is a variable-angle helix with a tapered expansion angle. In addition, the end line MN includes a stra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com