Double threaded connection preassembled snap joint

A double-threaded, threaded claw technology, applied in the field of clamping parts, can solve problems such as singleness, achieve the effects of improving utilization rate, simplifying assembly constraints, and improving the degree of generalization and serialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention is described in detail below through the examples, and the following examples are only exemplary and can only be used to explain and illustrate the technical solution of the present invention, rather than being interpreted as a limitation to the technical solution of the present invention.

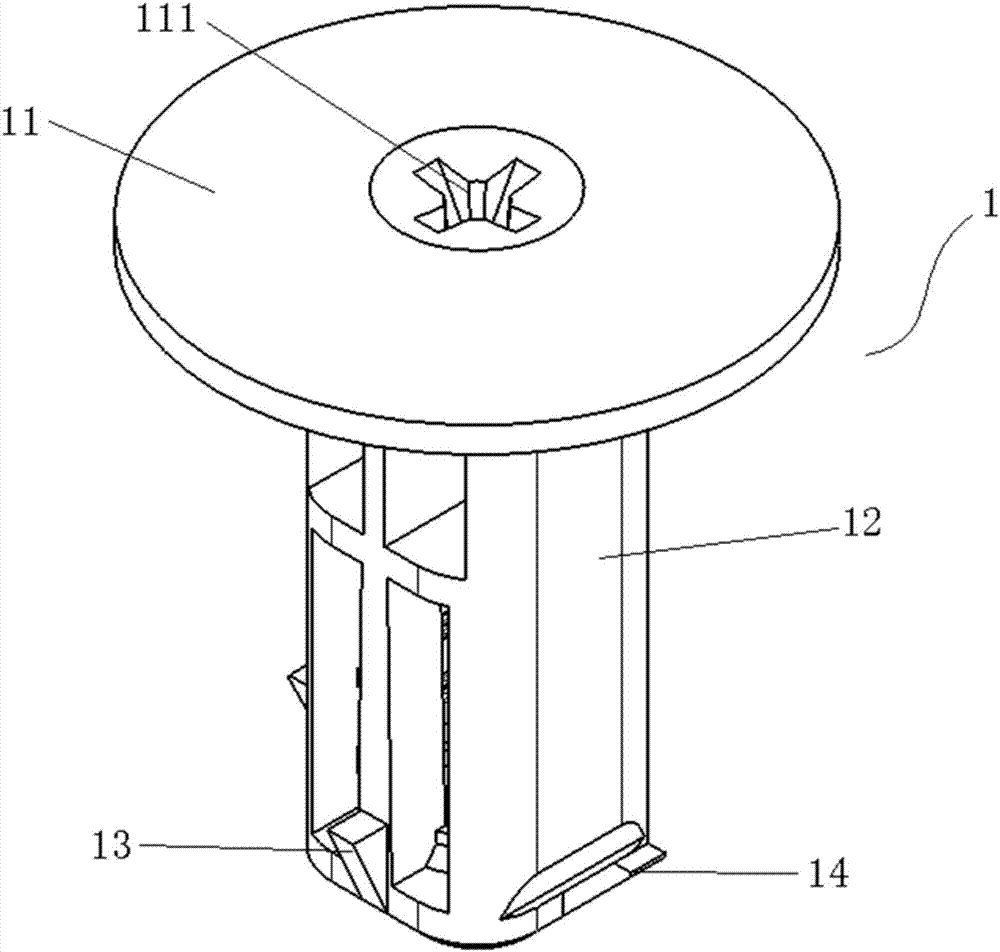

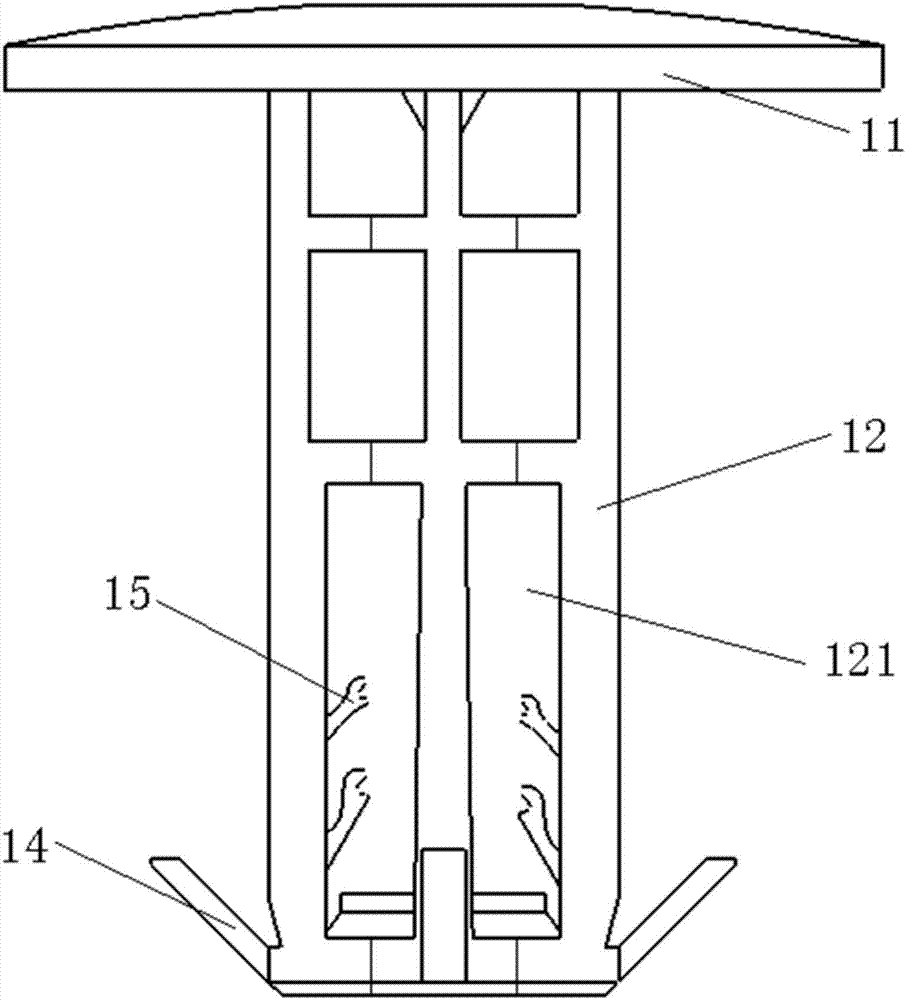

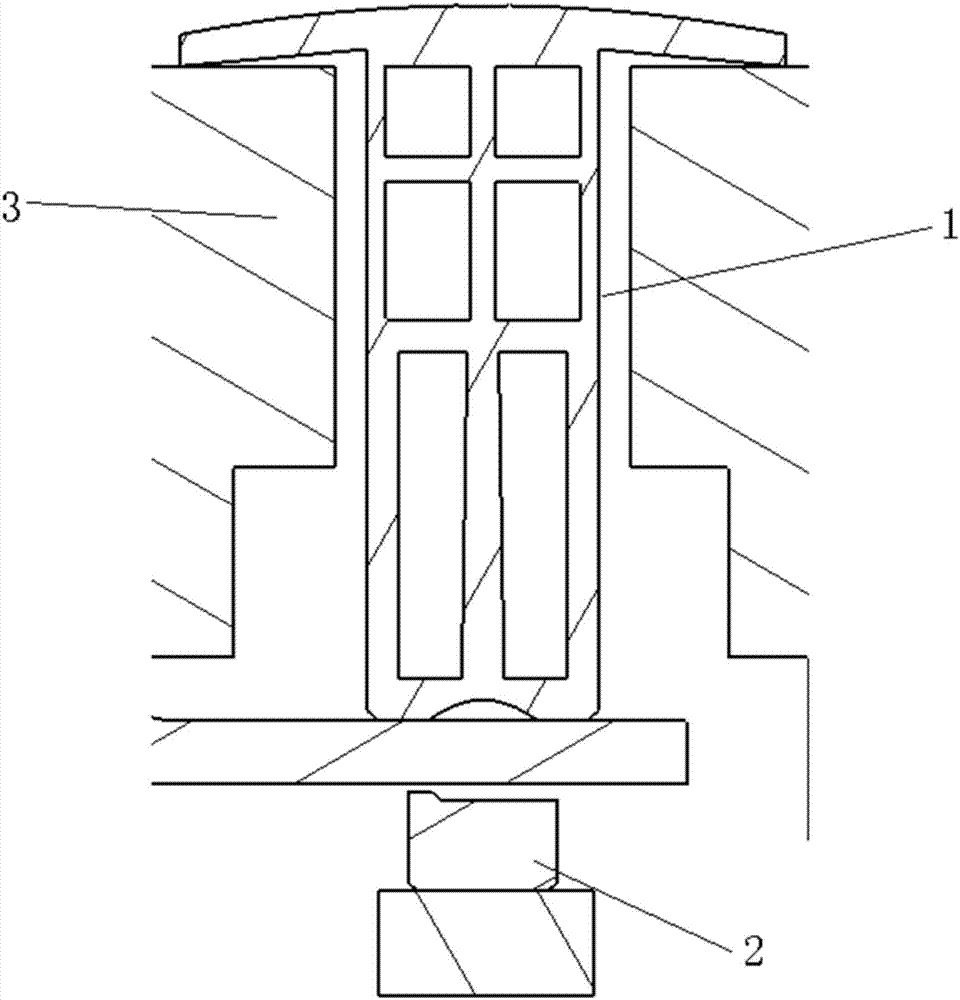

[0026] This application provides a double-threaded connection that can be pre-installed with buckles, such as Figure 1 to Figure 4 As shown, it includes a clamping part 1 and a fixing part 2, and the clamping part 1 and the fixing part 2 are fixedly connected by screws; in this application, the material of the clamping part is plastic material, which is integrally injection molded by plastic.

[0027] The clamping part 1 includes a clamping flange surface 11, a guide column 12, a limit card 13, a threaded claw 15 and an elastic limit clamp 14; a cross groove 111 is arranged on the surface of the clamping flange surface for Rotate the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com