Latch hook

A technology of latch and hook lock, which is applied in the direction of hooks, connecting components, mechanical equipment, etc., can solve the problems of heavy lifting and feeding, unreasonable structure, waste of materials, etc., and achieve low maintenance cost, simple structure, and simplified The effect of the action steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

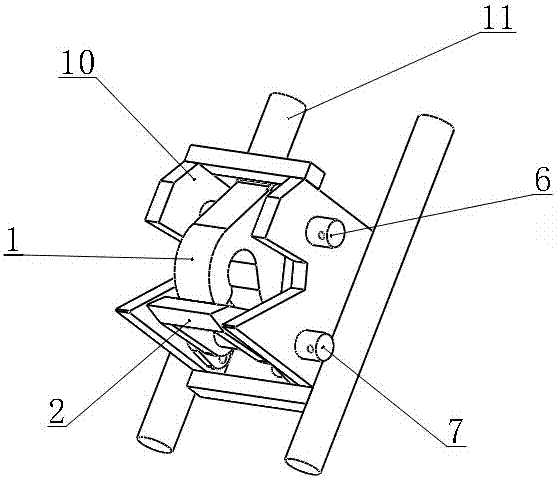

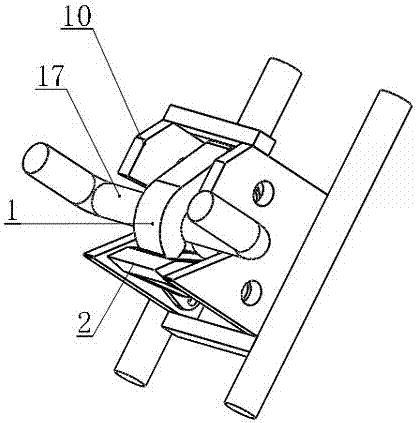

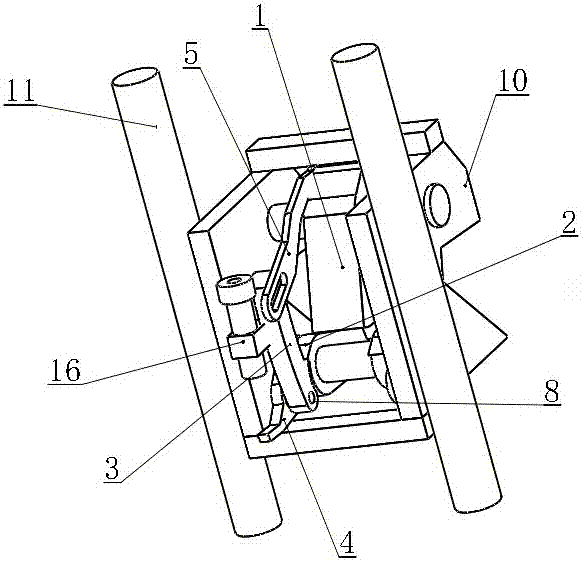

[0029] refer to Figure 1-10 , a latch hook, comprising a striker 1, a striker lock 2, a pawl 3, an unlocking plate 4, a striker shaft 6, a lock shaft 7 and a bracket 10, the bracket 10 is composed of two numbers with "7 The bracket plate 1001 of the shape gap and the frame surrounded by two slats, the gap of the bracket plate 1001 has the inclined edge 10011 of the plate surface, the vertical edge 10012 of the plate surface and the horizontal edge 10013 of the plate surface, and the inclined surface of the plate surface on the support plate 1001 Along 10011 is an inclined sliding surface, when there is no buckle successfully, the feeding cart can retreat along the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com