BIM-based engineering quantity extraction system and method for beam-slab prefabrication and cast-in-place structures

An extraction method and extraction system technology, which are applied in the field of BIM-based beam-slab prefabrication and cast-in-place structure engineering quantity extraction system, can solve the problems of a large number of prefabricated components, cumbersome calculation, and error-prone, and improve calculation accuracy and efficiency. performance, reduce calculation time, and calculate accurately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in further detail below in conjunction with specific embodiments. However, it should not be understood that the scope of the above-mentioned themes of the present invention is limited to the following implementation examples, and all technologies realized based on the content of the present invention belong to the scope of the present invention.

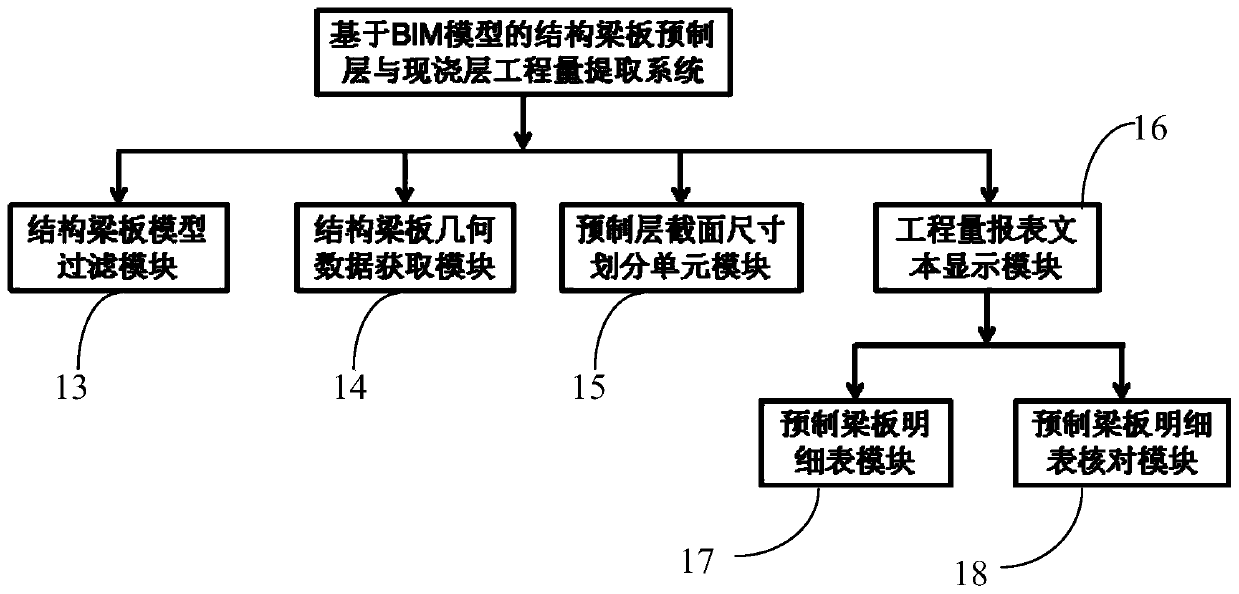

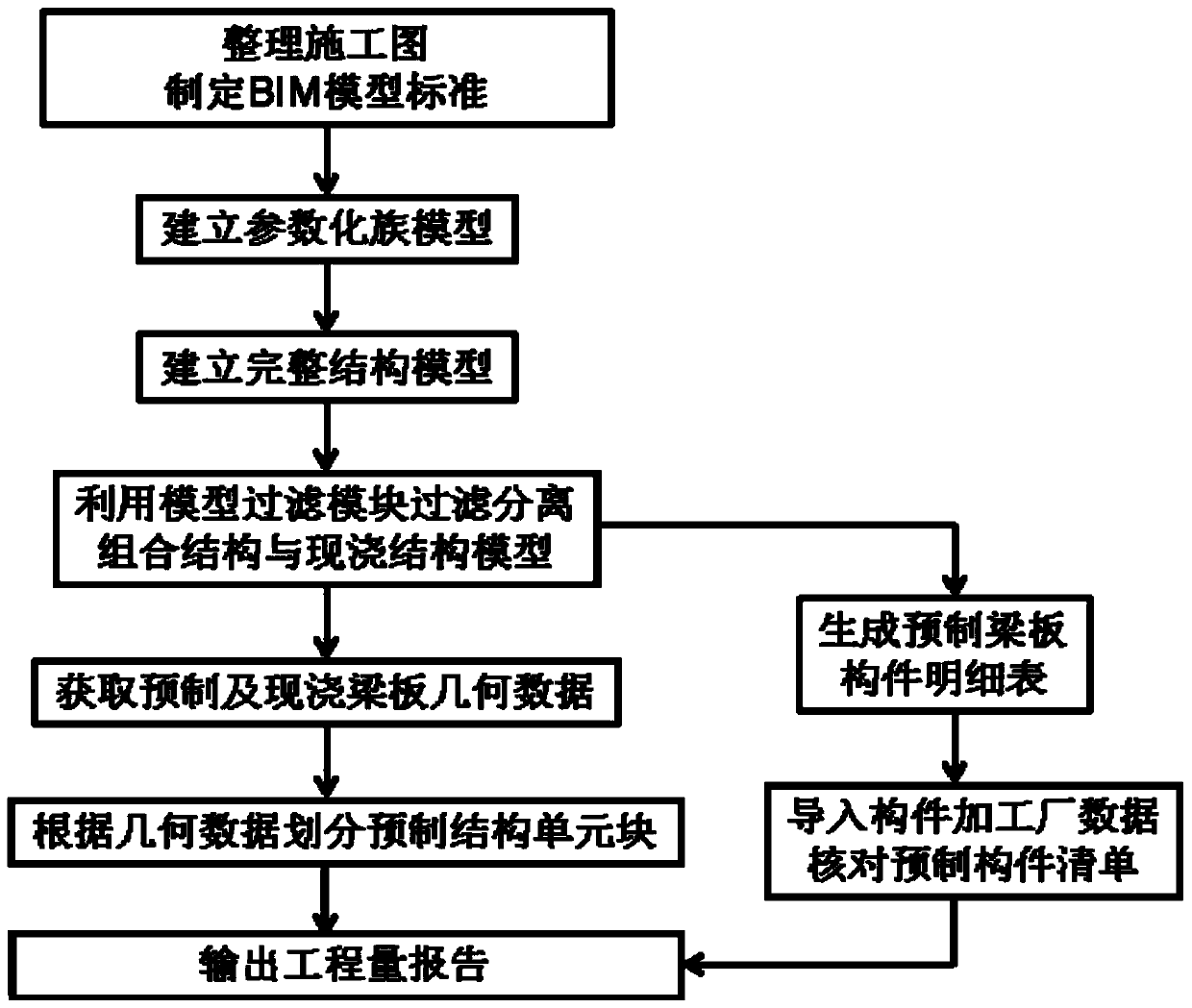

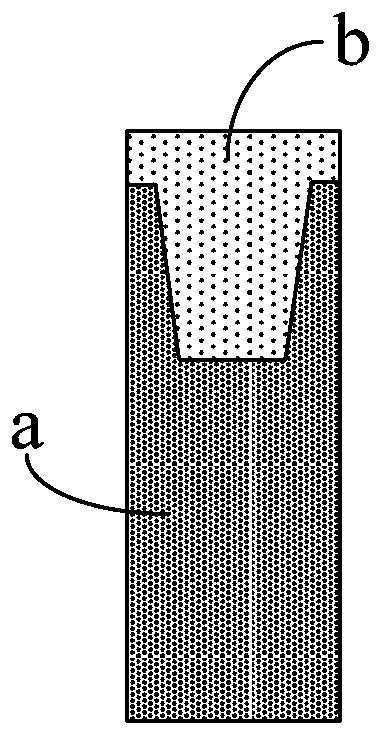

[0045] In the on-site construction of construction projects, cost control is the main factor for project profitability, and engineering quantity calculation is the key link of cost control. Since conventional engineering calculation methods cannot accurately and efficiently distinguish the cast-in-place and prefabricated layers of prefabricated composite beams and slabs, In addition, when separating the cast-in-place and prefabricated layers, it is necessary to manually identify and calculate, the workload is huge, cumbersome, and it is easy to make mistakes. The present invention utiliz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com