Abrasive pad, method for forming same, method for monitoring grinding

A technology of grinding pad and grinding layer, which is applied to grinding machine tools, grinding tools, grinding devices, etc., can solve the problem of low effective utilization rate of grinding pads, maximize effective utilization rate, accurately monitor usage, and avoid damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] As mentioned in the background art, the effective utilization rate of the polishing pad in the prior art is low.

[0033] In one embodiment, the wear degree of the polishing pad is judged according to the following manner: (1) judge the wear degree of the polishing pad according to the use time of the polishing pad; (2) judge the loss of the polishing pad according to the number of wafers polished by using the polishing pad (3) According to the use time of the polishing pad and the number of wafers polished by the polishing pad, whichever arrives first judges the degree of wear of the polishing pad.

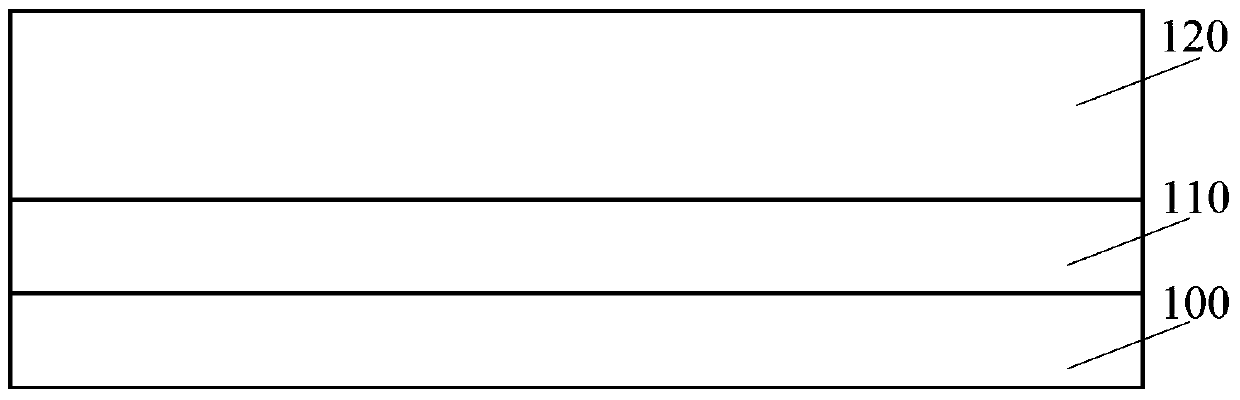

[0034] Corresponding, abrasive pads, ref. figure 1 , comprising: an adhesive layer 100 ; a matrix layer 110 located on the adhesive layer 100 ; an abrasive layer 120 located on the matrix layer 110 .

[0035] Research finds that the reason that the effective utilization rate of grinding pad is low in the above-mentioned embodiment is:

[0036] The monitoring of the degre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com