Heat net water purifier

A technology for purifiers and heating network water, applied in chemical instruments and methods, water/sewage treatment, water/sewage treatment equipment, etc., can solve the problems of low temperature of heating network pipes, affecting heating quality, and difficulty in cleaning, etc. Achieve scientific and reasonable structural design, ensure work efficiency, and ensure the effect of operating safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

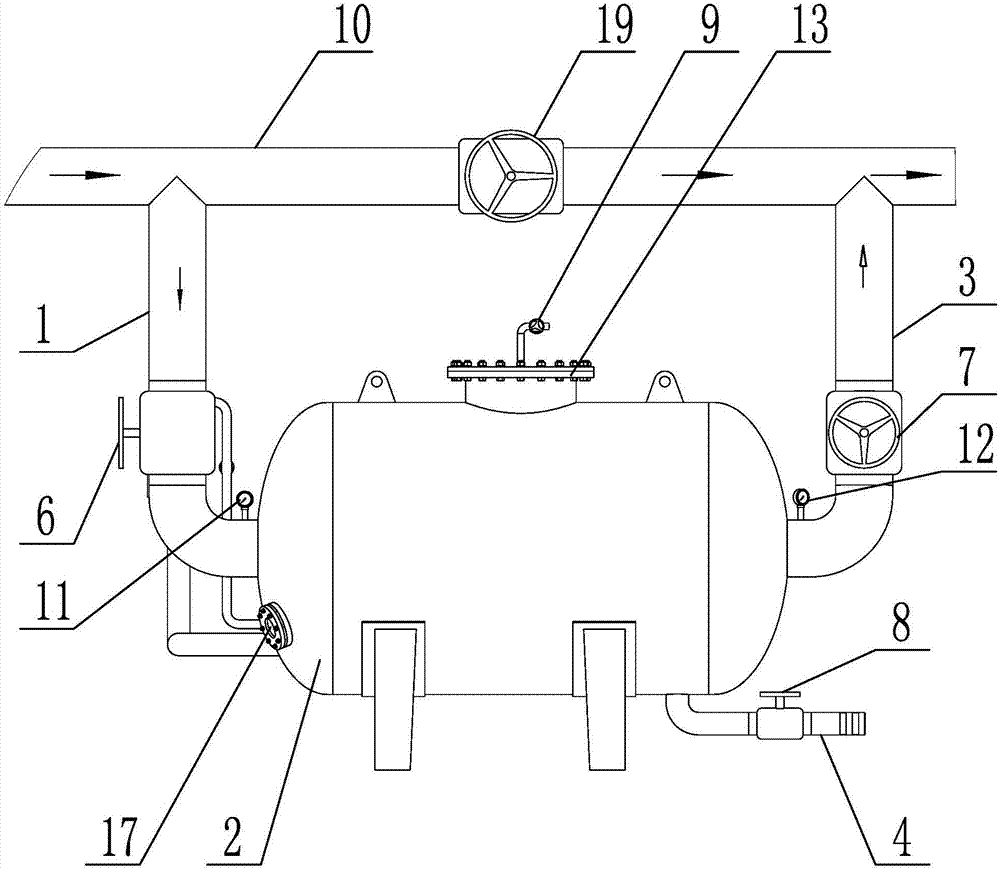

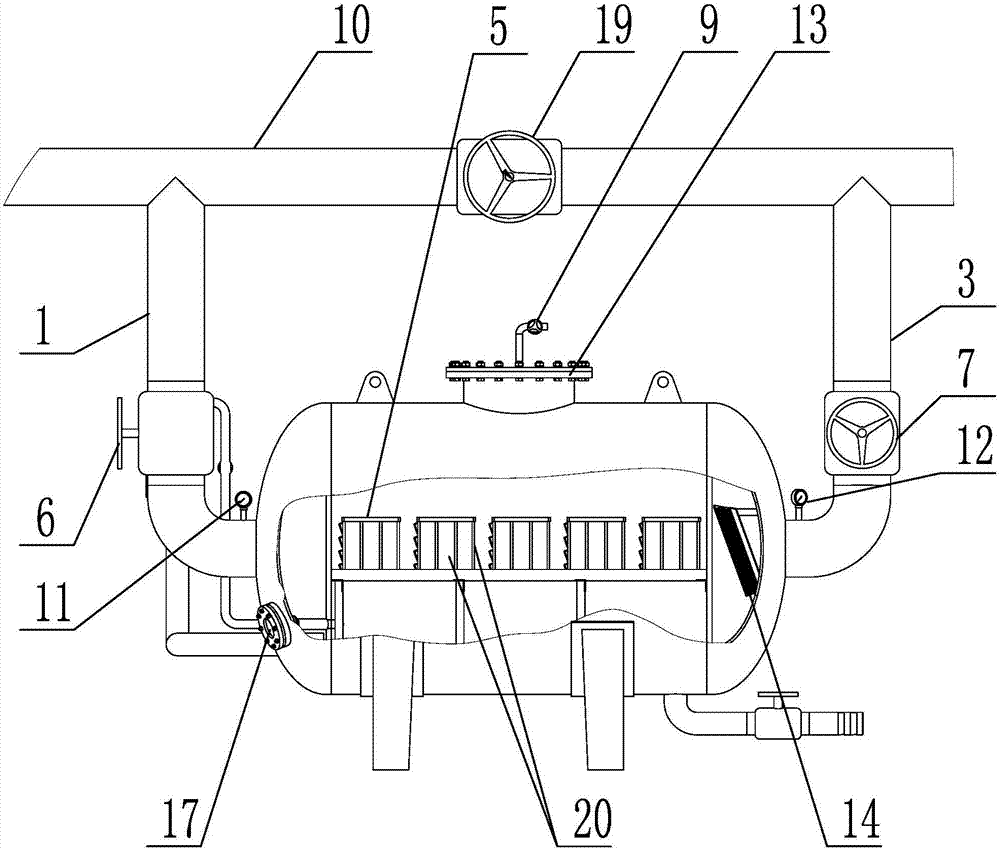

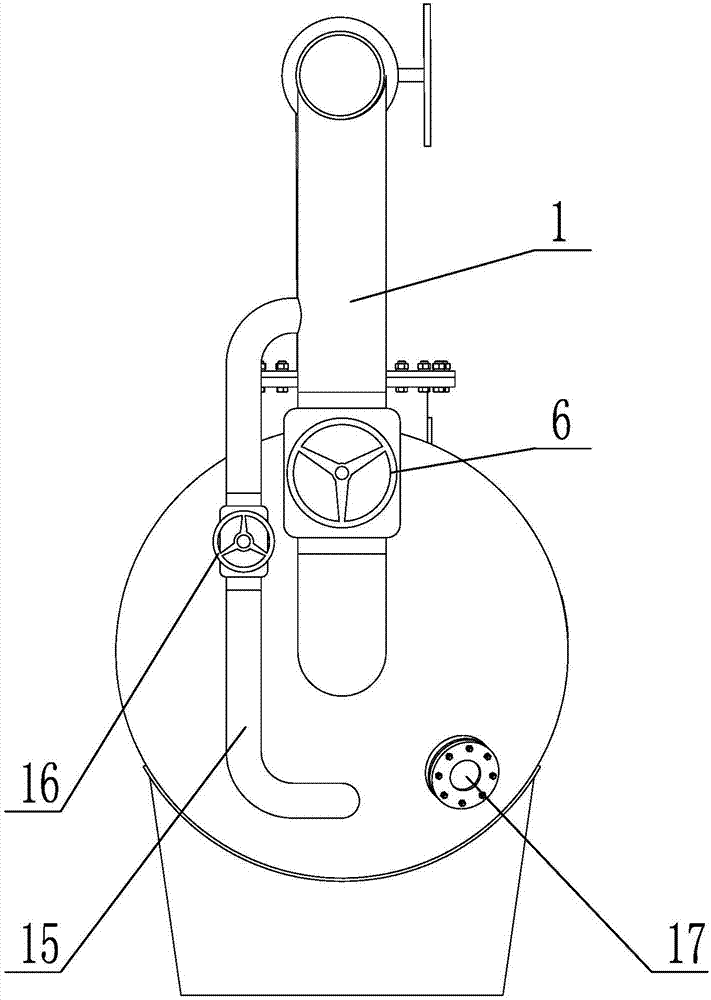

[0036] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 Describe this embodiment, this embodiment comprises water inlet pipe 1, tank body 2, outlet pipe 3, sewage pipe 4, water inlet valve 6, water outlet valve 7, sewage valve 8, air valve 9 and several magnetic rod groups 5, described The water inlet end of the water inlet pipe 1 is connected with the return pipe 10 of the secondary network of the heating network, the water outlet end of the water inlet pipe 1 is connected with one end of the tank body 2, and the other end of the tank body 2 is connected with the water inlet end of the water outlet pipe 3 The water outlet end of the outlet pipe 3 is connected with the return pipe 10 of the secondary network of the heating network, and the several magnetic bar groups 5 are arranged in the tank body 2, and the bottom of the tank body 2 is connected with a sewage pipe 4, and the tank body 2 The top of the body 2 ...

specific Embodiment approach 2

[0039] Specific implementation mode two: combination figure 1 and figure 2 To illustrate this embodiment, in this embodiment, the water inlet pipe 1 is provided with a water inlet pressure gauge 11 , and the water outlet pipe 3 is provided with a water outlet pressure gauge 12 . Other unmentioned structures and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0040] Specific implementation mode three: combination figure 1 , figure 2 and image 3 This embodiment is described. In this embodiment, a manhole door 13 is arranged on the top of the tank body 2 , and the air valve 9 is arranged on the manhole door 13 . Other unmentioned structures and connections are the same as those in the first or second embodiment.

[0041] Specific implementation mode four: combination figure 1 , figure 2 and image 3 To illustrate this embodiment, in this embodiment, the tank body 2 is provided with a large-aperture blocking net 14, and the large-aperture blocking net 14 is detachably connected to the water inlet end of the water outlet pipe 3, and each magnetic rod group 5 is close to the water outlet. One end of the water pipe 3 and both sides of the magnetic rod group 5 are respectively provided with a small-diameter blocking net 20 .

[0042] In this embodiment, both the large-aperture blocking net 14 and the small-aperture blocking net 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com