Dual mode synchronous rectification control circuit for dcm and ccm

A control circuit and synchronous rectification technology, which is applied in the direction of control/regulation system, electrical components, and adjustment of electrical variables, etc., can solve problems such as breakdown of internal devices of rectifier chips, reduction of rectification efficiency, and reduction of rectification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Below in conjunction with accompanying drawing, describe technical scheme of the present invention in detail:

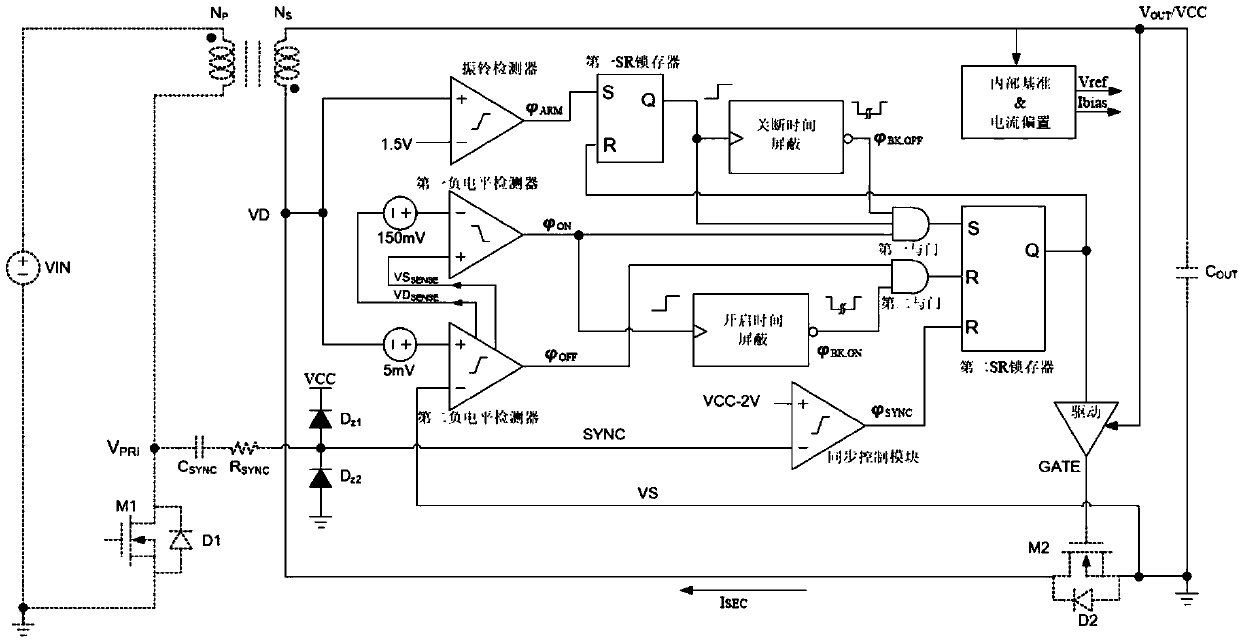

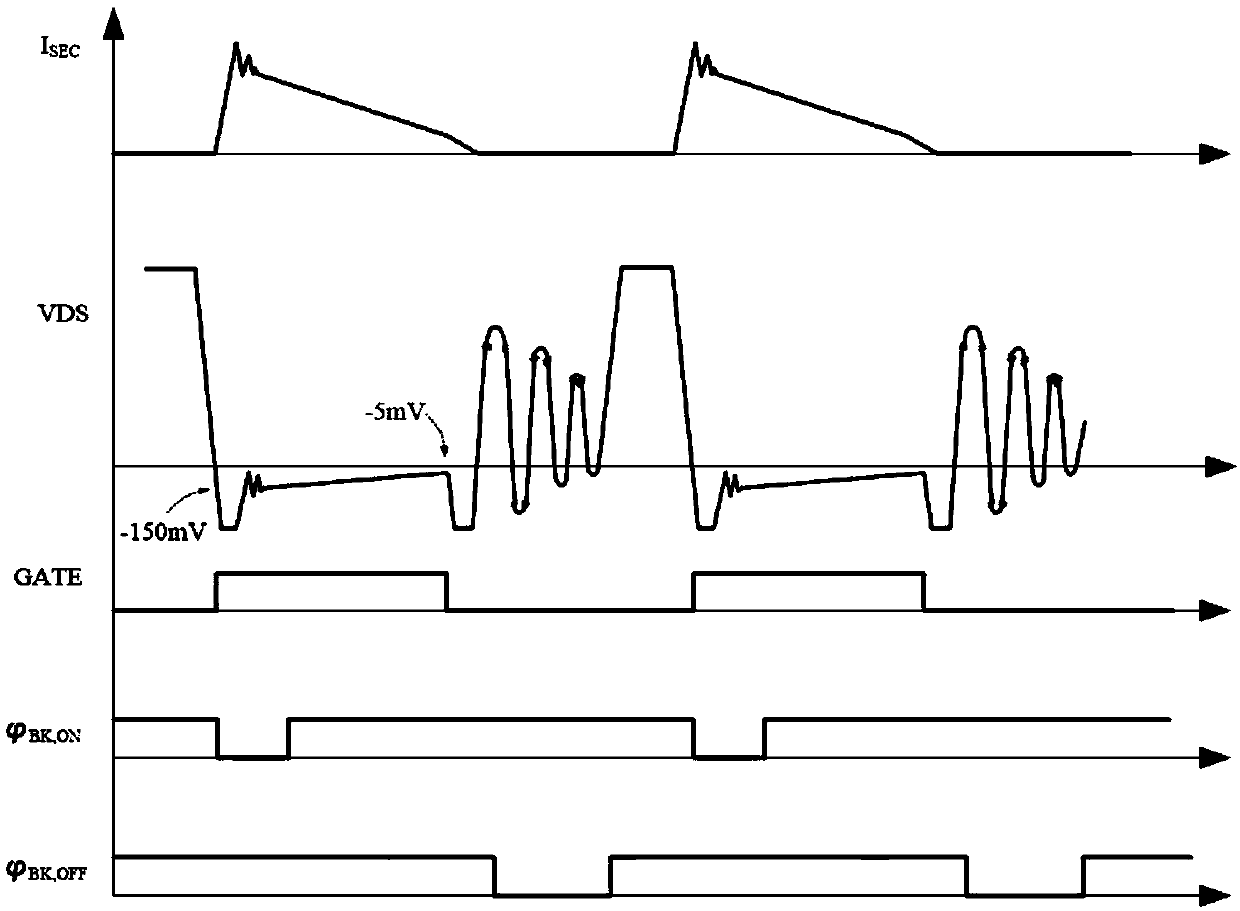

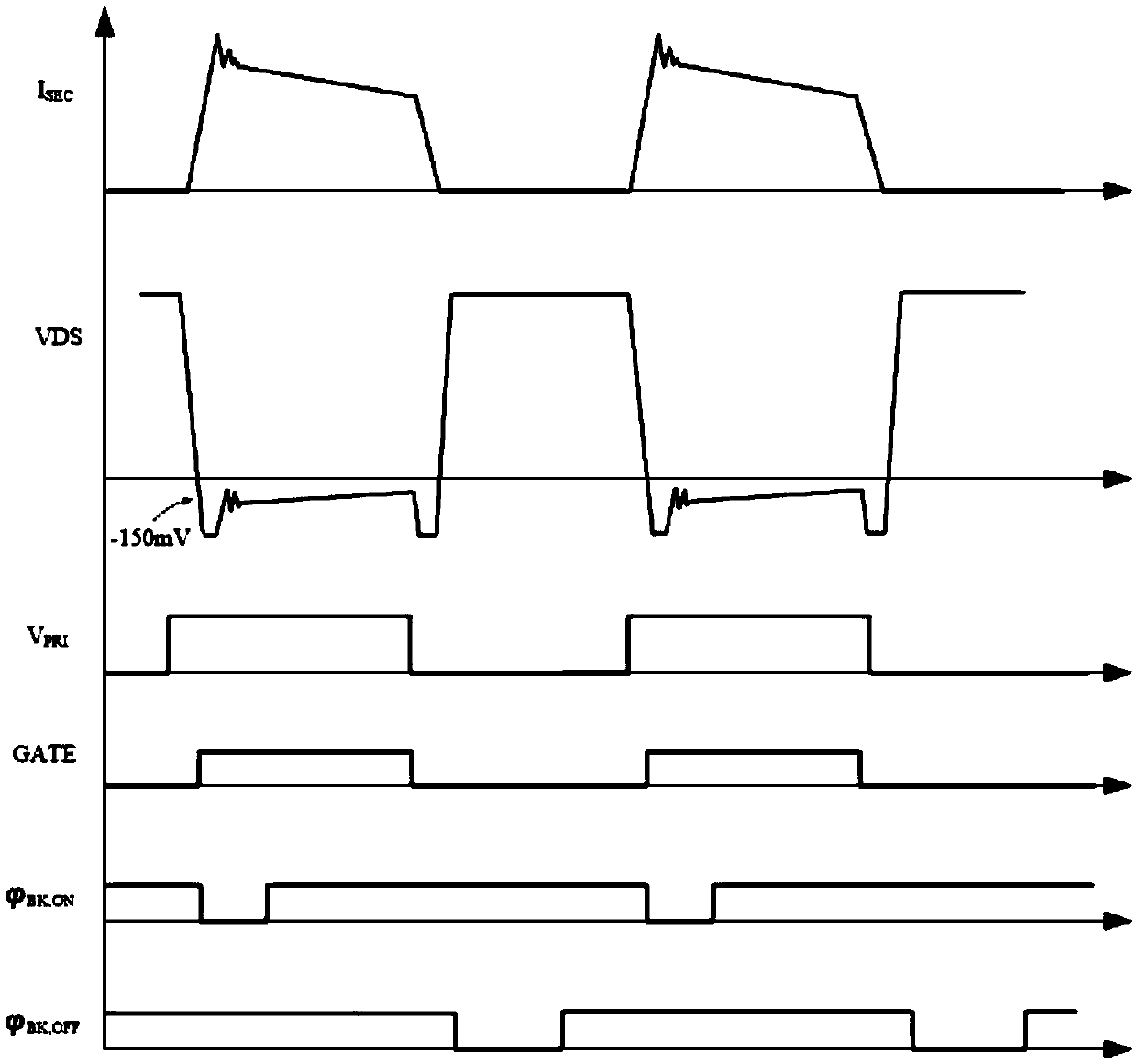

[0046] Taking the dual-mode synchronous rectification control circuit suitable for DCM and CCM proposed by the present invention as an example when it is applied to a flyback converter flyback, such as figure 1 , wherein the solid line part is the circuit topology of the present invention, which consists of an internal reference and current bias module, a ringing detector, a first negative level detector, a second negative level detector, a first SR latch, a second Two SR latches, off-time mask module, on-time mask module, synchronous control module, first AND gate, second AND gate, first Zener tube D Z1 , the second Zener tube D Z2 , drive module, the first sampling terminal samples the drain level VD of the synchronous rectifier M2 in the flyback converter, the second sampling terminal samples the source level of the synchronous rectifier M2, and the input ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com