Clamping robot

A robot and clamping mechanism technology, applied in the direction of manipulators, program-controlled manipulators, claw arms, etc., can solve the problems of high cost, need to improve the operation accuracy, complex structure of the manipulator, etc., and achieve low production cost, simple structure and precise operation The effect of increasing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

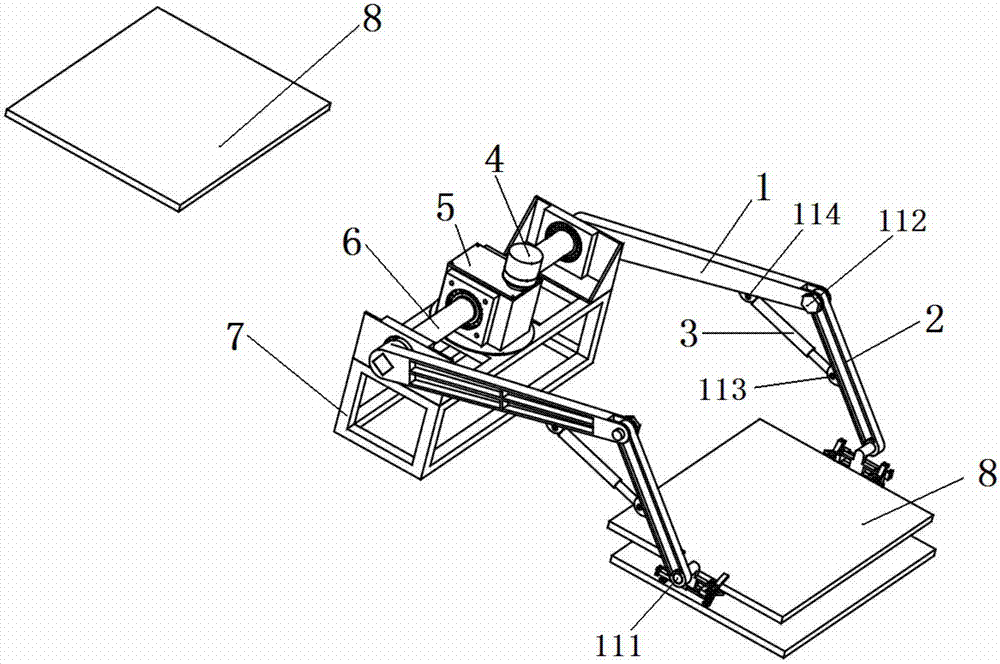

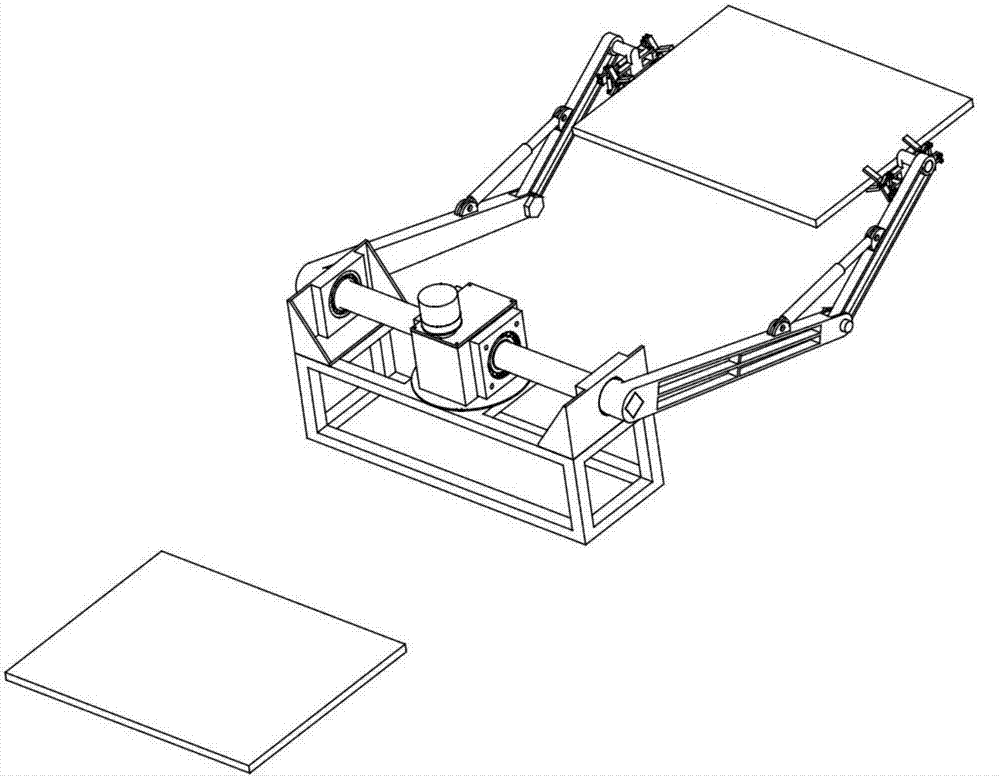

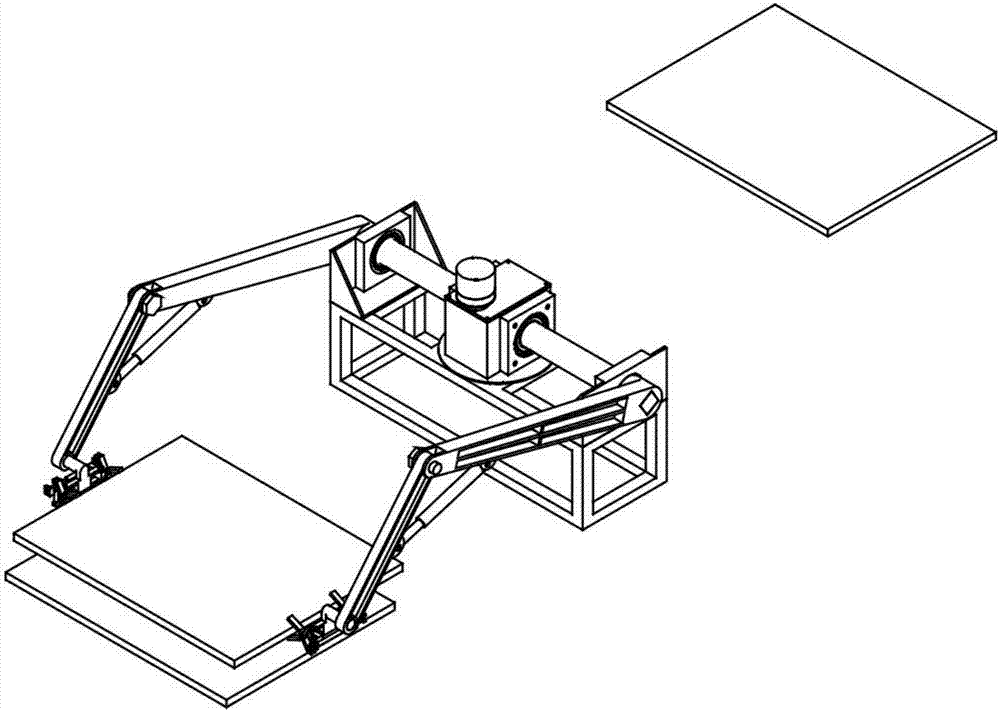

Embodiment 1

[0022] A clamping robot, the clamping mechanism includes a clamping seat 9A, a first connecting rod 8A, a second connecting rod 7A, a first telescopic rod 5A, a second telescopic rod 6A, a third telescopic rod 10A, a first clip Holding arm 1A, second holding arm 2A, third holding arm 3A and fourth holding arm 4A;

[0023] The middle part of the first clamping arm 1A and the second clamping arm 2A is connected into a scissors fork by a rotating pair 101, and the rotating pair 101 is installed on one end of the first connecting rod 8A, and the middle part of the first connecting rod 8A passes through the rotating pair 2 102 is connected to the clamping seat 9A, the other end of the first connecting rod 8A is connected to one end of the third telescopic rod 10A through the rotating pair 105, and one end of the first telescopic rod 5A is connected to the first clamping arm 1A through the rotating pair 107. One end, the other end of the first telescopic rod 5A is connected to one e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com