Field track and production operation main unit operated thereon and rain type watering machine

A track and field technology, applied in tracks, movable tracks, watering devices, etc., can solve the problems of surprise prevention and control of diseases and insect pests, poor drought resistance, large resistance to natural conditions, and inability to operate in series, etc., to achieve production management projects. Good effect, saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

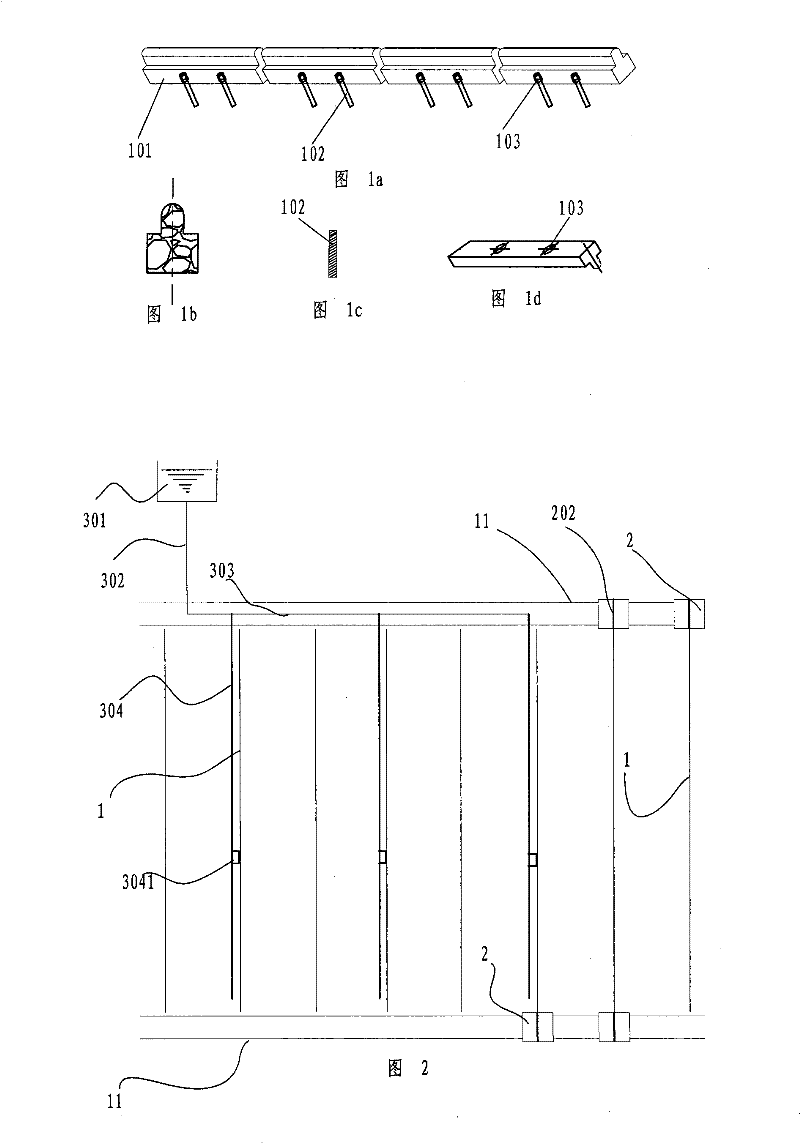

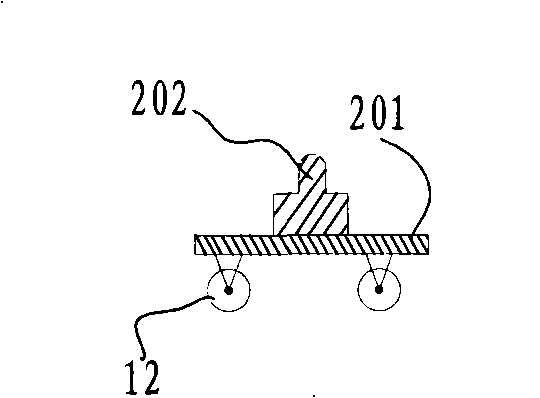

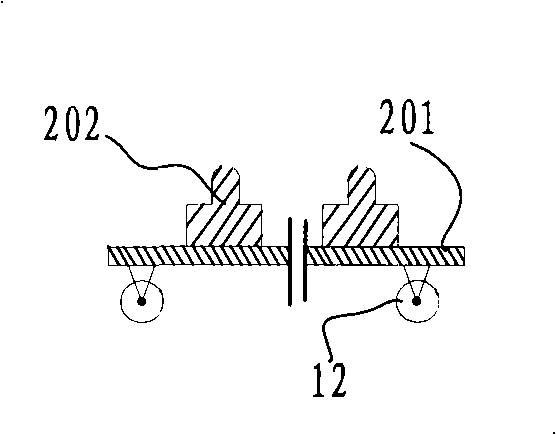

[0035] As shown in Figures 1a-1d, the field track of the present invention is formed by prefabricated track sections 101 of the same specification and shape arranged in a "one" shape, and fixed end-to-end in the middle of the field. The track shape of the track segment 101 is arc-shaped above, square at the bottom, and flat at the bottom. The bottom of each track section 101 is provided with two fixing holes 103. When the track section 101 is installed, the foundation below the track is compacted, the prefabricated fixed pile 102 is erected, and the lower end is inserted into the compacted foundation soil layer perpendicular to the ground. depth, the length of the upper end exposed to the ground will be slightly less than the depth of the fixing hole 103, and the shape of the end of the fixing pile 102 is adapted to the shape of the fixing hole 103, so that the upper end of the fixing pile 102 is just inserted into the fixing hole 103, so that Securely and securely secure the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com