Corrosion-free and scratch-free metal paint remover as well as preparation method and application thereof

A paint remover and non-corrosion technology, applied in the direction of chemical paint/ink remover, coating, etc., can solve the problems of scratching the substrate, affecting the appearance, affecting the secondary coating, etc., achieving low cost and improving efficiency , long-lasting antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

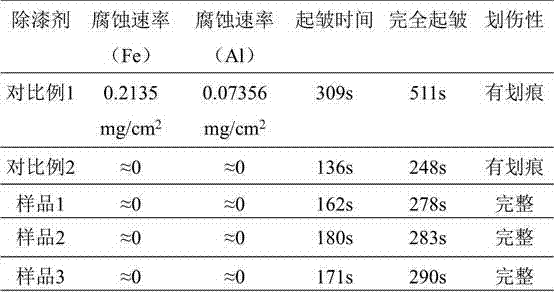

Examples

Embodiment 1

[0062] Embodiment 1-3 provides a kind of non-corrosion non-scratch metal paint remover, and its preparation steps are as follows: Deionized water is slightly heated to 40~50 o C, then slowly add the viscous agent, stir at 200~300r / min for 20min to completely dissolve, then add carbon dioxide nanotubes, surfactants and bactericides in sequence, continue to stir until a uniform brown-yellow solution is obtained, cool down, and then Add the main solvent, co-solvent, penetrant, stabilizer, and ethanol in sequence, seal the reactor, and keep stirring at room temperature for 2-4 hours to obtain a non-corrosive and non-scratch metal paint remover. The steps for preparing the inorganic additive oxidized carbon nanotubes are as follows: 10 g of carbon nanotubes are placed in a 250 mL flask, and 60 mL of H2O with a mass fraction of 98% is added. 2 SO 4 and 15 mL of HNO with a mass fraction of 40% 3 , ultrasonic vibration for 60min, then stirring, 100 o Under the condition of C water ...

Embodiment 2

[0074] A kind of non-corrosion non-scratch metal paint remover, its component consists of:

[0075] Main solvent: N-methylpyrrolidone: methyl benzoate=1:1.5, 40wt.%;

[0076] Co-solvent: benzyl alcohol, 8.5wt.%;

[0077] Inorganic additive: oxidized carbon nanotube solution, 20wt.%;

[0078] Thickener: one or more of methylcellulose, polyacrylamide, carboxymethylcellulose, hydrated lithium magnesium silicate, 1.5wt.%;

[0079] Penetrant: one or both of nonylphenol polyoxyethylene ether and fatty alcohol polyoxyethylene ether, 1.5wt.%;

[0080] Surfactant: one or more of cetyltrimethylammonium bromide, polyoxyethylene sorbitan fatty acid ester, dodecylethoxysulfobetaine, 2wt.%;

[0081] Stabilizer: 2,2'-methylenebis(4-methyl-6-tert-butylphenol): 0.75wt.%;

[0082] Fungicide: isothiazolinone, 0.75wt.%;

[0083] The rest is a mixture of deionized water and ethanol with a volume ratio of 3:1, which is marked as sample No. 2.

Embodiment 3

[0085] A kind of non-corrosion non-scratch metal paint remover, its component consists of:

[0086] Main solvent: N-methylpyrrolidone: methyl benzoate=1: 2, 45wt.%;

[0087] Cosolvent: benzyl alcohol, 12wt.%;

[0088] Inorganic additive: oxidized carbon nanotube solution, 30wt.%;

[0089] Thickener: one or more of methylcellulose, polyacrylamide, carboxymethylcellulose, hydrated lithium magnesium silicate, 2wt.%;

[0090] Penetrant: one or both of nonylphenol polyoxyethylene ether and fatty alcohol polyoxyethylene ether, 2wt.%;

[0091] Surfactant: one or more of cetyltrimethylammonium bromide, polyoxyethylene sorbitan fatty acid ester, dodecylethoxysulfobetaine, 3wt.%;

[0092] Stabilizer: 2,2'-methylenebis(4-methyl-6-tert-butylphenol): 1wt.%;

[0093] Fungicide: isothiazolinone, 1wt.%

[0094] The rest is a mixture of deionized water and ethanol with a volume ratio of 3:1, which is marked as sample No. 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap