Bridge support

A technology of bridge bearings and bearing plates, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as high bridge bearings, reduced stability, complex structures, etc., and achieve the effect of improving sliding capacity and large turning angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

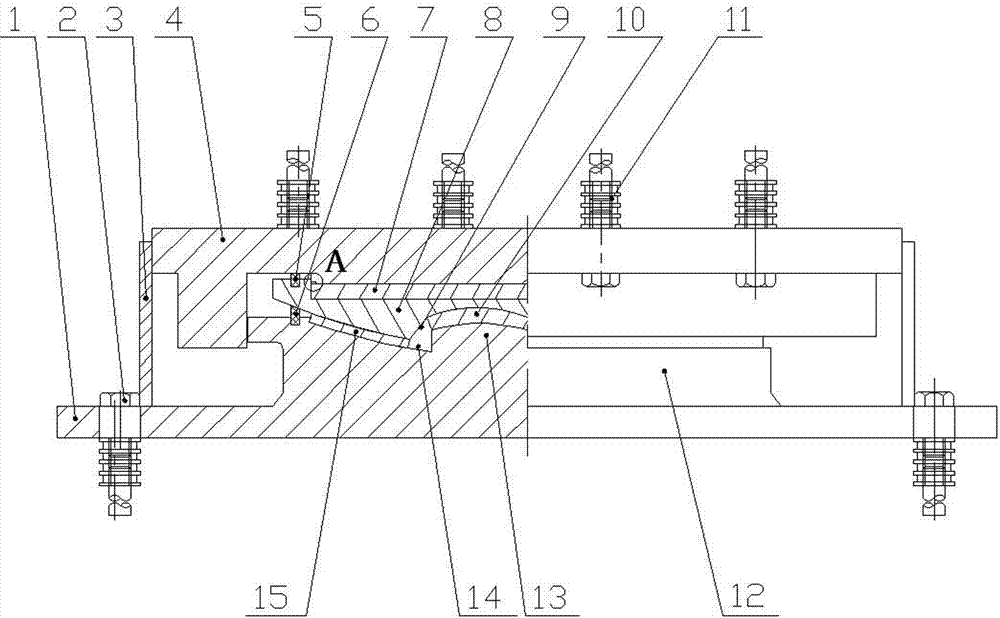

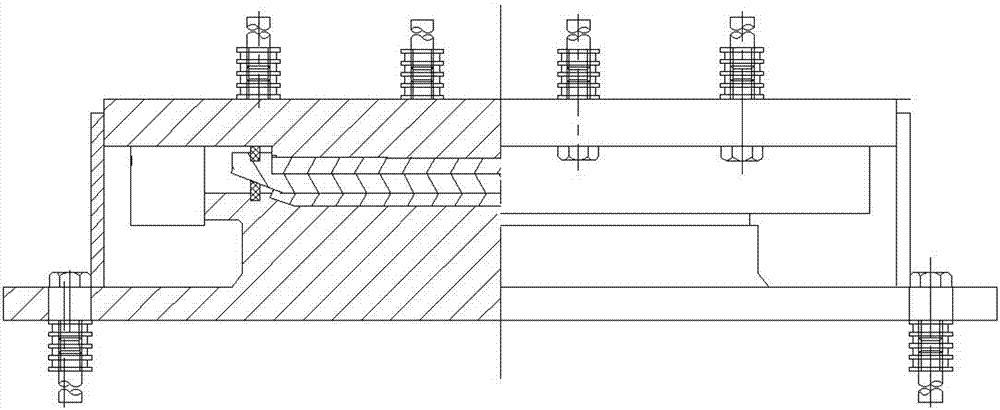

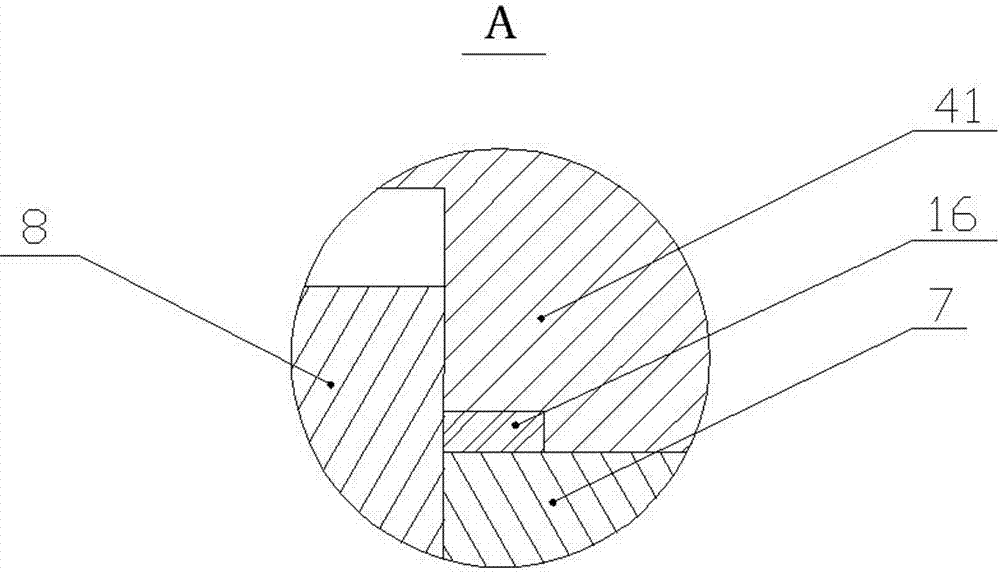

[0027] Bridge supports generally have an up-and-down structure, wherein the upper support plate 4 and the lower support plate 1 can be considered as two seat plates, wherein the upper support plate 4 is generally fixed to the girder body of a bridge by bolts 11 of the upper support plate Connection, the lower bearing plate 1 is generally fixedly connected with, for example, a bridge pier through the lower bearing plate bolts 2 . A friction structure is generally constructed between the upper support plate 4 and the lower support plate 1 to provide a moving or rotating function.

[0028] It is known that if the connection between the beam body and the pier column is only a fixed connection, the connection stability is relatively good, but the response ability to the deformation of the beam body or to vibration is relatively poor. How to use sliding parts for connection can correspond to the deformation of the beam body or the response ability of vibration is relatively strong, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com