Rotor type oil pump capable of reducing oil supply pressure pulsation intensity and flowing noise

A rotor-type oil pump and pressure pulsation technology, which is applied to engine components, pressure lubricants, machines/engines, etc., can solve problems such as unstable oil supply pressure, high pulsation intensity, and large flow noise, so as to improve reliability, Effect of reducing pressure pulsation intensity and flow noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

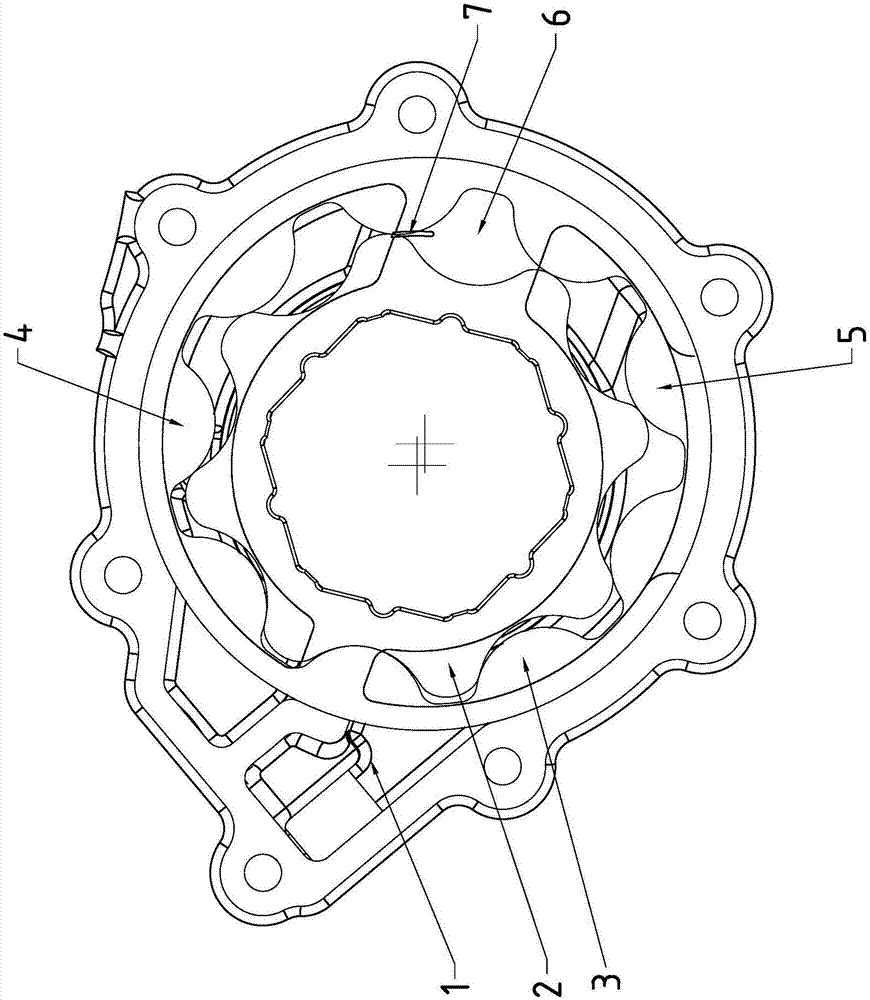

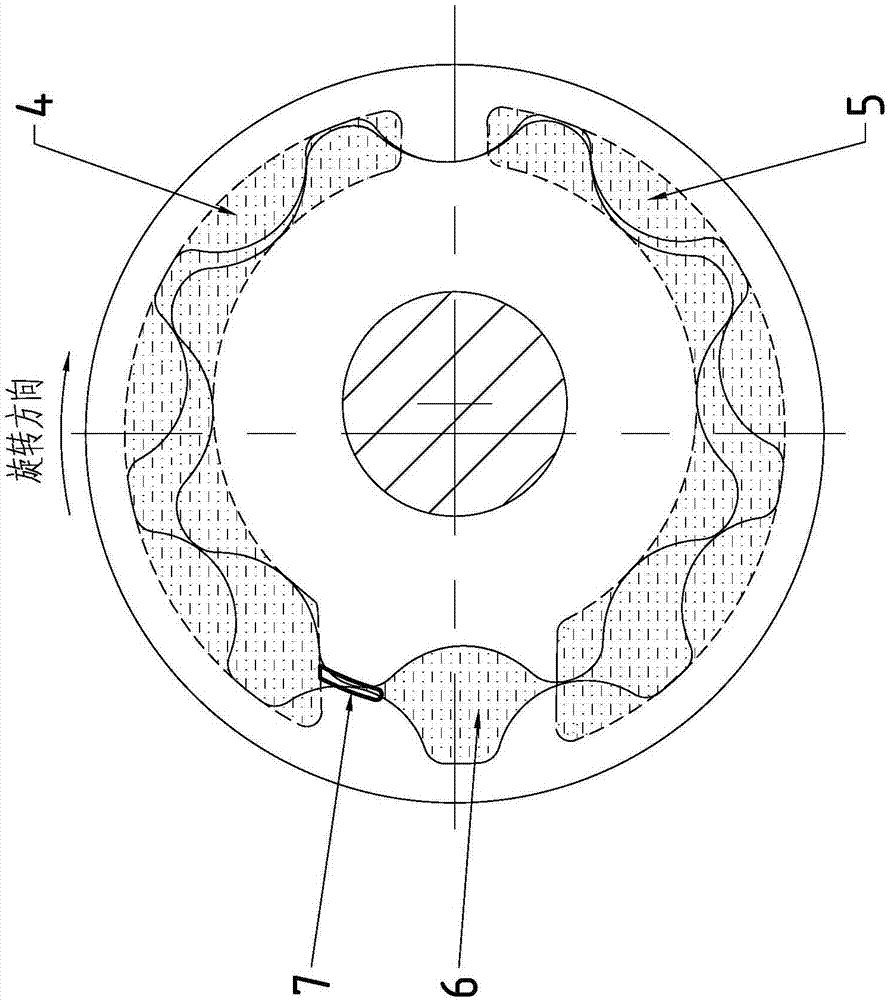

[0016] like Figure 1~2 As shown, the present invention mainly includes an oil pump casing 1, and an inner rotor 2 and an outer rotor 3 which are engaged with each other are arranged inside the oil pump casing 1. On the end surface of the oil pump casing 1 facing the inner rotor 2 and the outer rotor 3, there are crescent grooves 4 in the oil outlet area and crescent grooves 5 in the oil inlet area, and an oil trapped cavity 6 is formed between the inner rotor 2 and the outer rotor 3 .

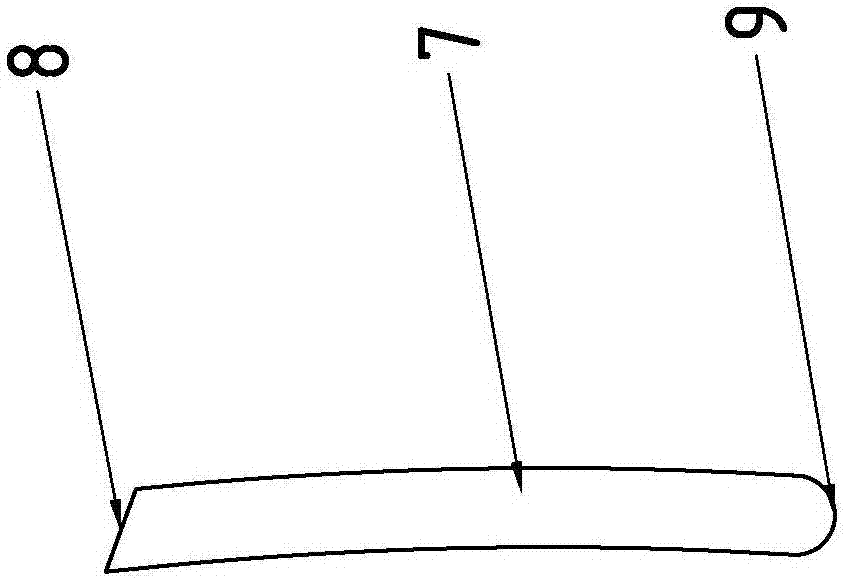

[0017] In order to reduce the oil pressure pulsation intensity and flow noise in the oil outlet area, the oil pump housing 1 is provided with a balance oil groove 7, the starting end face 8 of the balance oil groove 7 communicates with the big end of the crescent groove 4 in the oil outlet area, and the end face 9 of the balance oil groove 7 It extends from the big en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com