Load-sensitive multi-way valve and hydraulic system

A load-sensing, multi-way valve technology, applied in the direction of fluid pressure actuation system components, fluid pressure actuation devices, servo motor components, etc., can solve the problem that the pressure of the load-sensing pump cannot be unloaded, the Ls pressure fluctuates greatly, and it is easy to generate shocks, etc. problems, to achieve the effect of improving flow control performance, ensuring coordinated actions, and working reliably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

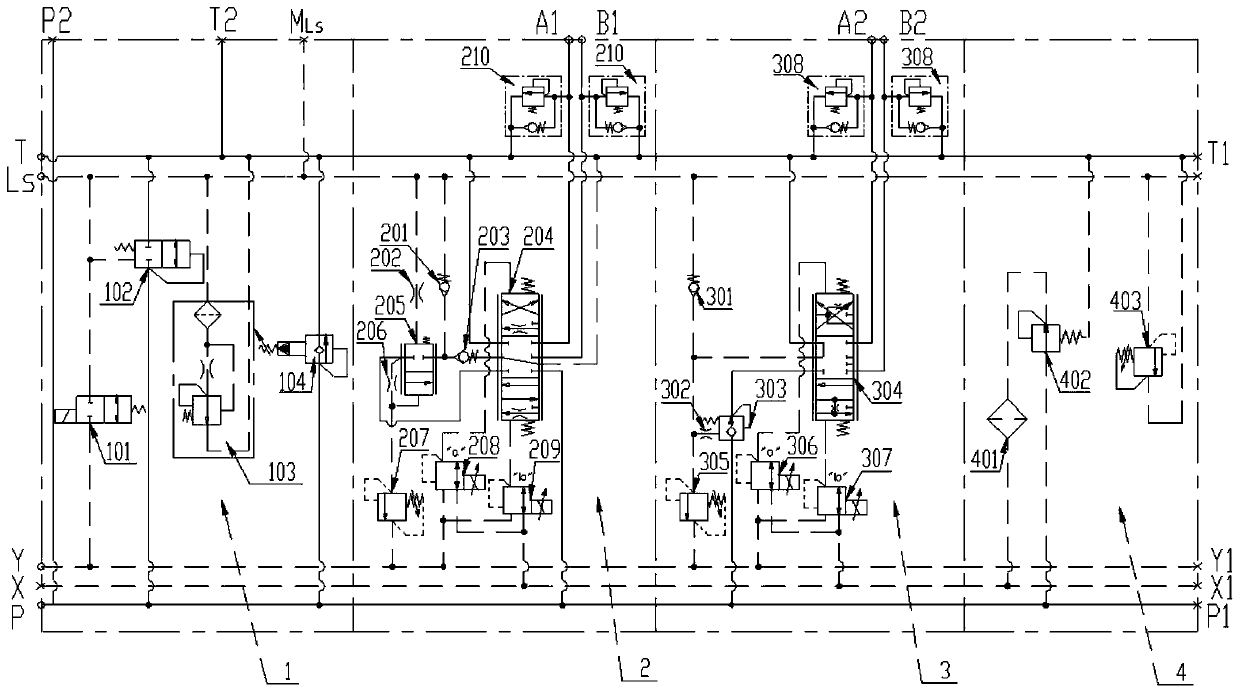

[0055] In some embodiments, such as figure 1 As shown, a load-sensing multi-way valve includes a first joint 1, a tail joint 4, and several post-valve compensation working joints 2 and several pre-valve compensation working joints 3 arranged between the first joint and the tail joint; the first joint 1. A number of post-valve compensation working couplers 2, a number of pre-valve compensation working couplers 3 and a tail coupler 4 are fixedly connected together by double-ended studs. P oil supply oil circuit, X pilot oil supply oil circuit, Y oil drain oil circuit, Ls load feedback oil circuit, T oil return oil circuit run through several post-valve compensation working joints 2 and several pre-valve compensation working joints 3 from the first joint 1 and taillink 4.

[0056] figure 1 Only one post-valve compensation working couplet 2 and one pre-valve compensation working couplet 3 are shown in . In actual application, multiple post-valve compensation working couplets 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com