Pipe fitting grooving machine and grooving processing technique for end of pipe fitting

A technology of rolling groove machine and pipe fittings, which is applied in metal processing, metal processing equipment, manufacturing tools, etc. It can solve the problems of easy scratches at the ends of pipe fittings and easy running of pipes, etc., to protect the touch screen, improve product quality, and improve processing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

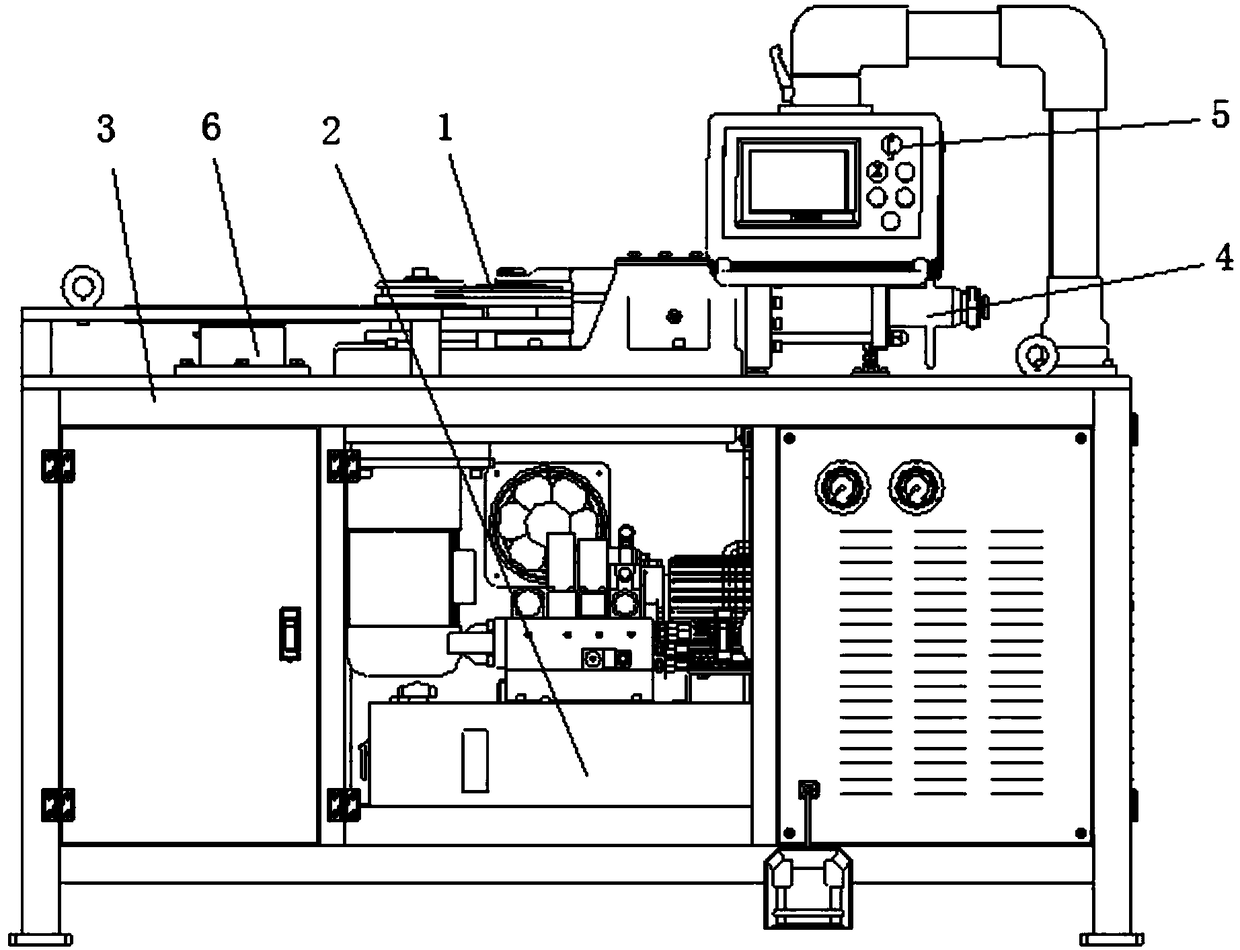

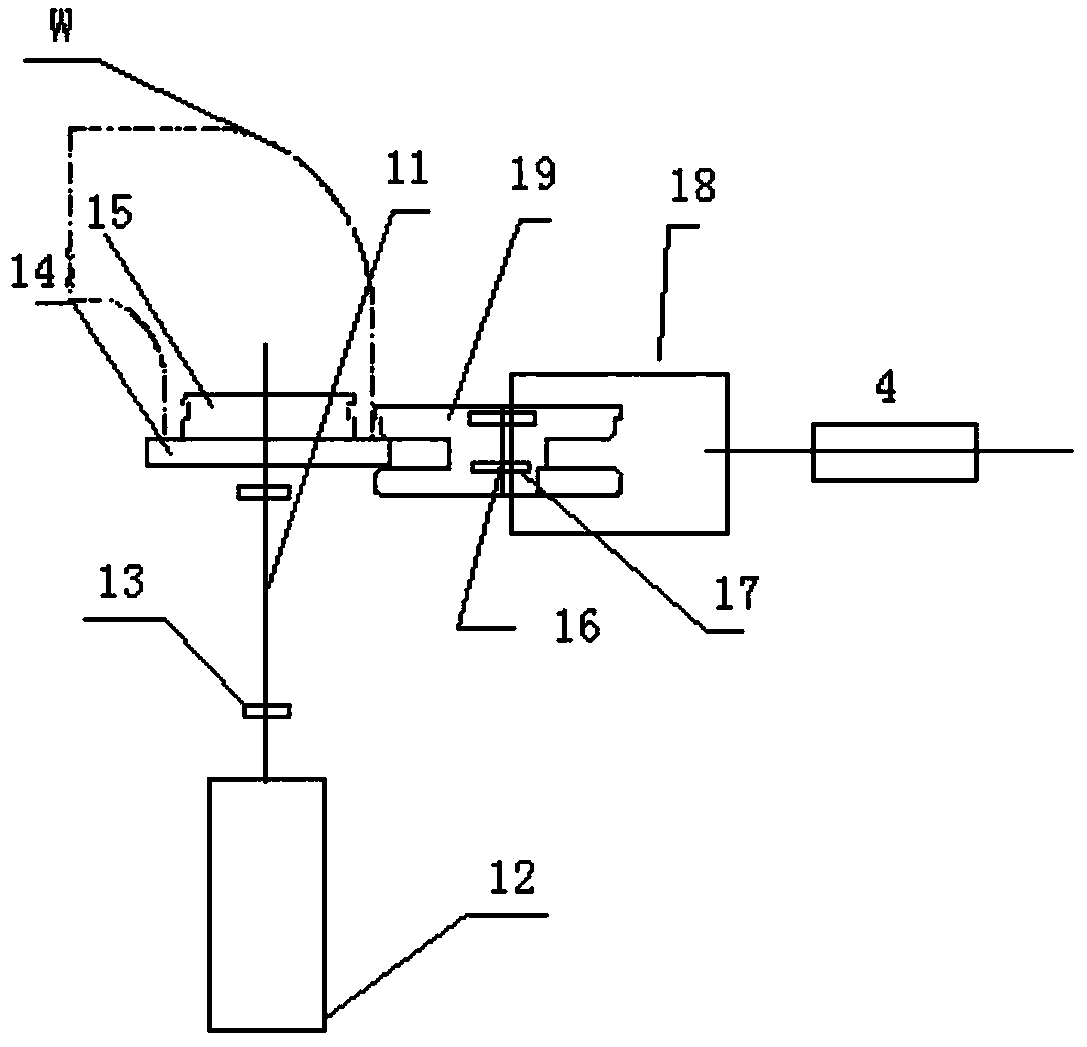

[0039] The invention discloses a pipe fitting rolling groove machine. see figure 2, which is a schematic view of the front structure of a preferred embodiment of the pipe fitting grooving machine of the present invention. As shown in the figure: it includes rolling grooving processing assembly 1, hydraulic assembly 2, frame 3, oil cylinder 4, touch screen assembly 5 and friction disc 6. The frame 3 has an operating platform and a supporting part located below the operating platform, and there is an accommodation space between the supporting parts under the operating platform. Wherein, the friction plate 6 is mainly arranged on the operating platform; the touch screen assembly 5 is arranged on the operating platform during use, and can be stored in the accommodation space after use; the oil cylinder 4 can be arranged on the operating platform; the hydraulic assembly 4 is mainly Set in the accommodation space; the rolling groove processing part of the rolling groove processin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com