Steam discharge in pulp or fiber refiners

A steam outlet, fiber separator technology, applied in pulp beating/refining method, fiber raw material, fiber raw material processing, etc. problem, to achieve the effect of uniform fiber quality, low specific energy consumption, and less micro-pulsation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Throughout the drawings, the same reference numerals are used for similar or corresponding elements.

[0028] As mentioned in the background section, there is a continuing need in the art for further improvements in the removal of steam from the refining zone of a refiner.

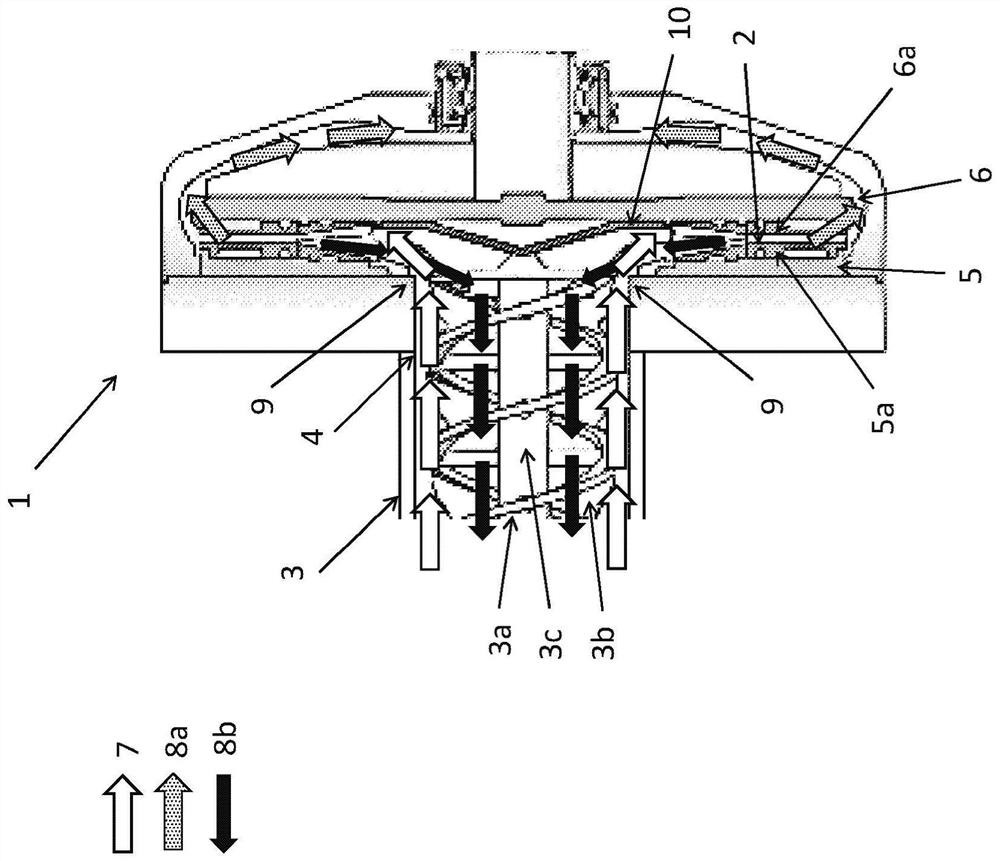

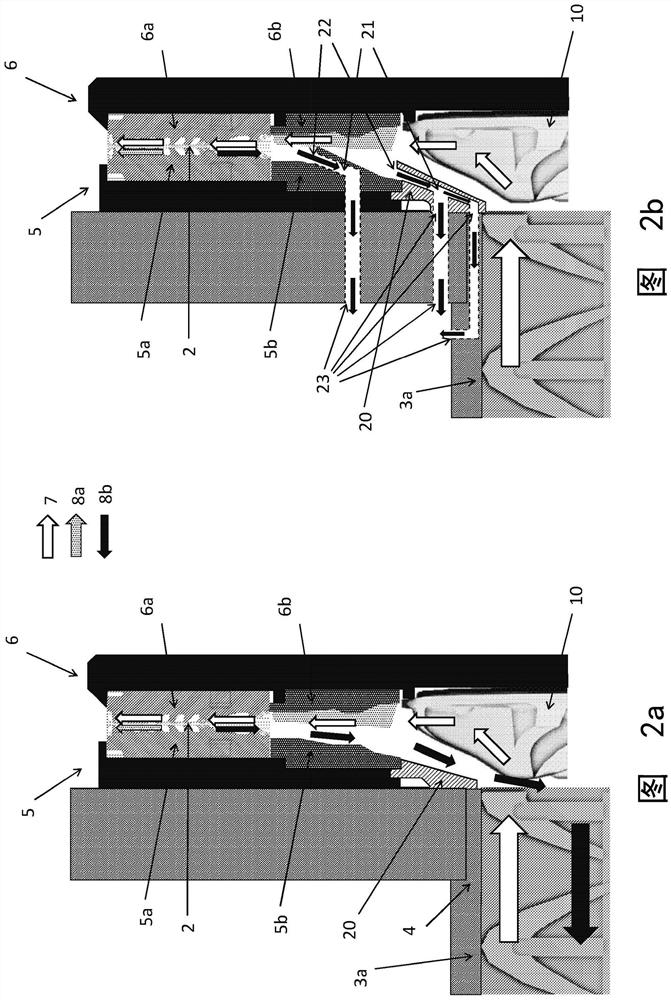

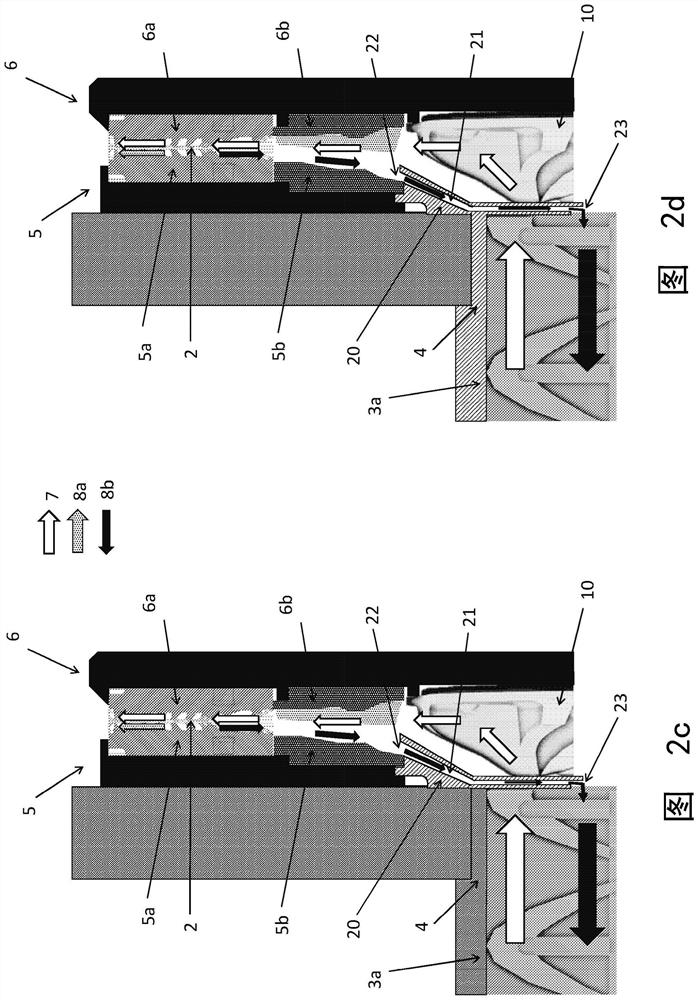

[0029] figure 1 is a schematic diagram of a typical defibrator arrangement in a pulp or fiber refiner. Here, a defibrator with a rotor and stator arrangement is described, but this embodiment can also be applied in a defibrator with two rotors. Lignocellulose-containing material 7, such as wood chips, is fed by a conveying screw / feed screw 3a, typically a belt feeder, via a feed channel 3 towards the defibrator 1 and through a material inlet opening 4 in the stator 5 into the refining disc, That is, the intermediate space between the stator 5 and the rotor 6 . The centrifugal force forces the material towards the periphery of the refining disc to emerge in the refining gap / space 2 between the ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com