Pressure intelligent control steam drier

A dryer and steam technology, applied in the direction of dryers, steam generation, steam generation methods, etc., can solve the problems of heating efficiency and low degree of intelligence, achieve enhanced heat transfer, improve intelligence, and ensure gas output rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

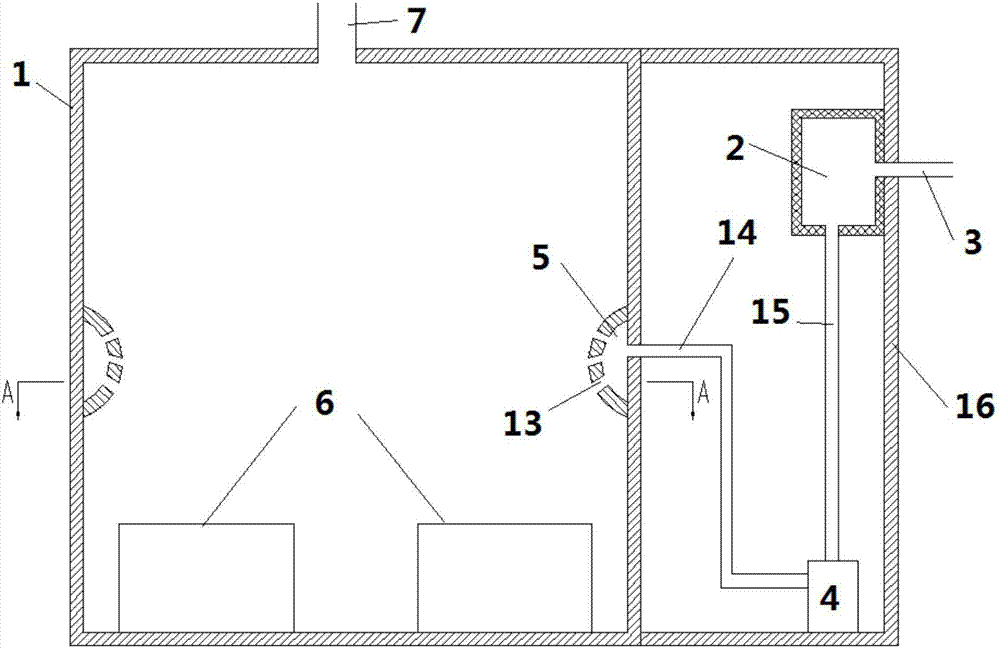

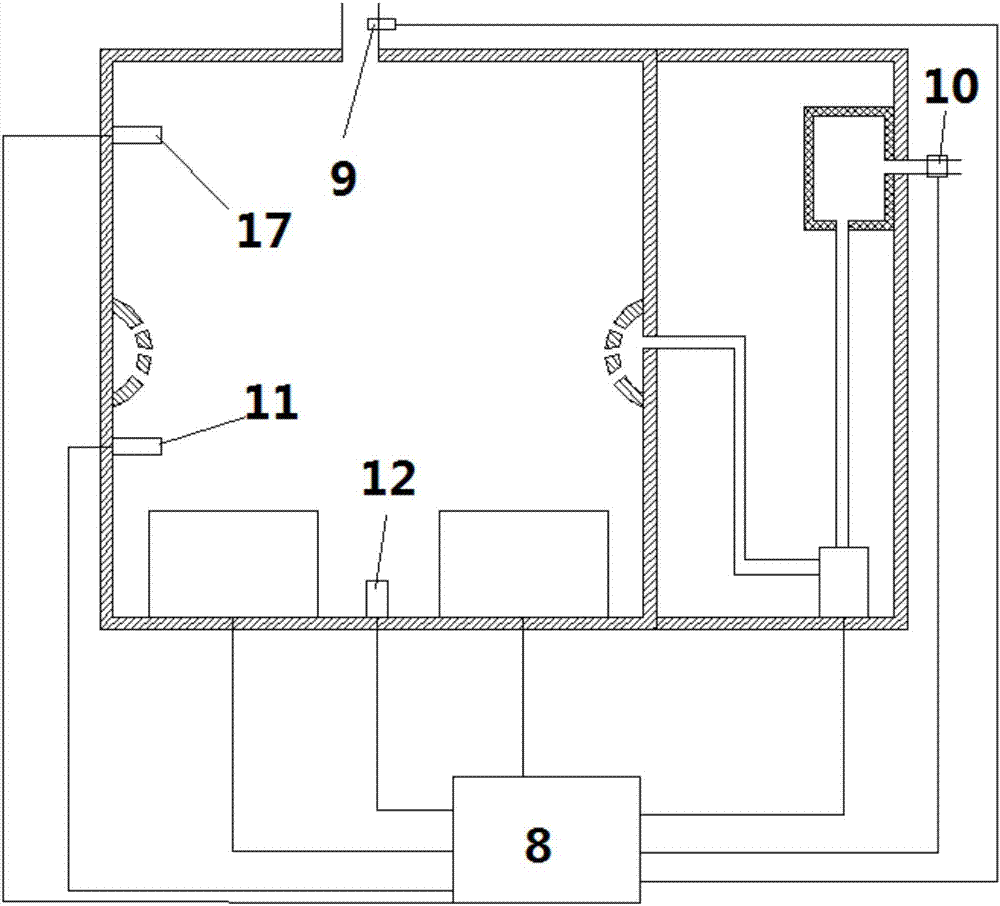

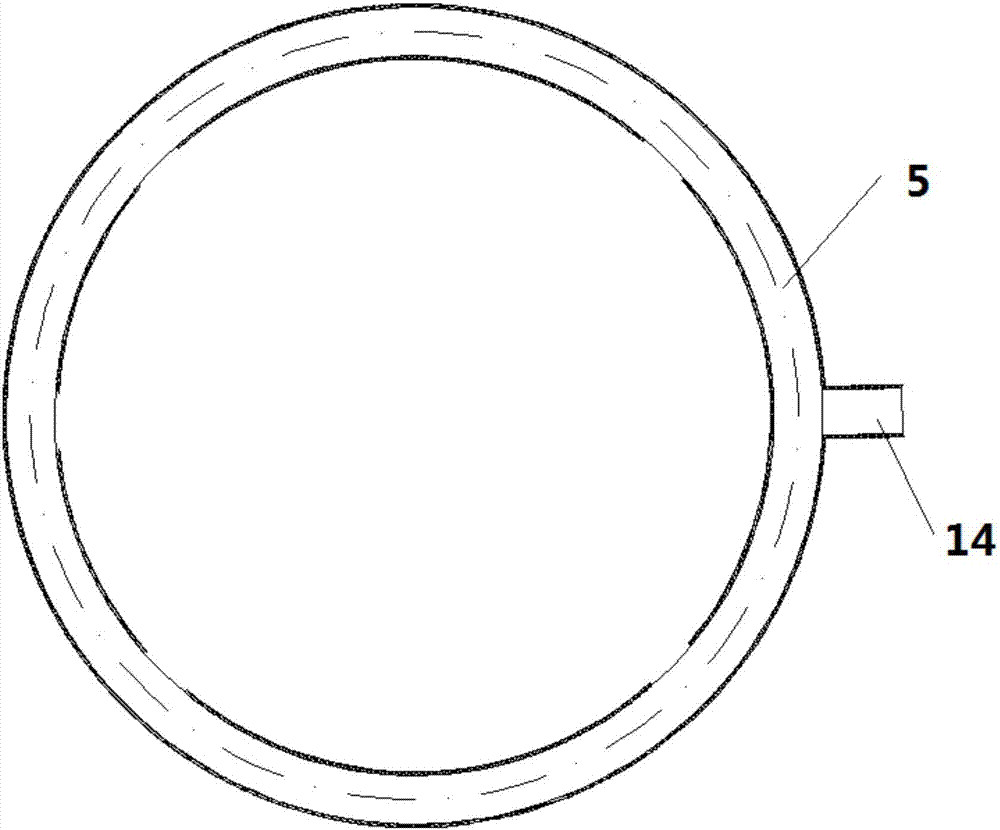

[0037] like figure 1 A steam dryer shown includes a furnace body 1, a water tank 2, and a water pump 4. The water tank 2 is connected to the water pump 4 through a pipeline 15, and the water pump 4 is connected to the furnace body 1 through a pipeline 14. The furnace body 1 An electric heating device 6 is arranged inside, a steam outlet pipeline 7 is arranged on the upper part of the furnace body 1 , and an inlet pipeline 3 is arranged on the water tank 2 . The steam outlet pipeline 7 is connected with a steam pipeline, and the material is dried through the steam pipeline. After the steam is utilized, it enters the water tank 2 through the inlet pipeline 3 to achieve the purpose of recycling.

[0038] The water enters the furnace body 1 from the water tank 3 through the water pump 4 , is heated in the furnace body 1 by the electric heating device 6 , and the generated steam is discharged through the steam outlet pipeline 7 .

[0039] Preferably, the steam discharged from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com