Gamma instrument automatic calibration device and method

An automatic calibration and gamma instrument technology, applied in the field of well logging, can solve the problems of bulky equipment, low ranging accuracy, low efficiency, etc., and achieve the effect of convenient automatic calibration, safety and accuracy assurance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

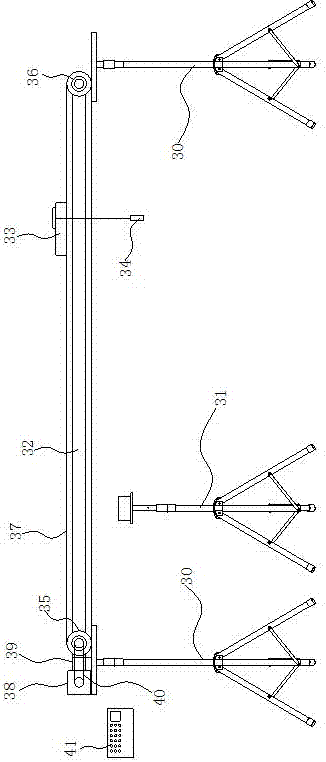

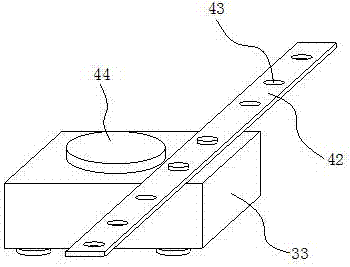

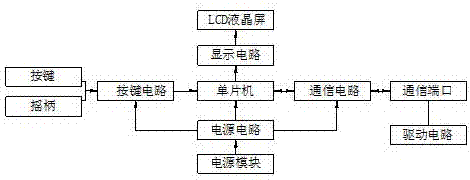

[0031] combine Figure 1-7 A gamma meter automatic calibration device shown includes two track support frames 30 and an instrument support frame 31, guide rails 32 are arranged between the two track support frames 30, and guide rails 32 are adapted to be used for hanging The sliding platform 33 of the standard source 34 can reciprocate back and forth along the guide rail 32 , and the guide rail 32 is used to guide the sliding platform 33 . The sliding platform 33 is used to hang the standard source 34, and the standard source 34 can be fixedly connected with the sliding platform 33 directly through a pull rod. For the convenience of hanging the standard source 34 and improving the versatility of the present invention, a better way is, as figure 2 As shown, the standard source suspension strut 42 perpendicular to the guide rail 32 is set on the sliding platform 33, the center of the standard source suspension strut 42 is connected with the upper surface of the sliding platfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com