Positioning mechanism used for machining of three-pin shaft fork of automobile transmission system

A technology of three-pin shaft fork and transmission system, which is applied in the direction of manufacturing tools, workpiece clamping devices, etc., can solve the problems that cannot meet the positioning of three-pin shaft fork, and achieve the effect of automatic positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

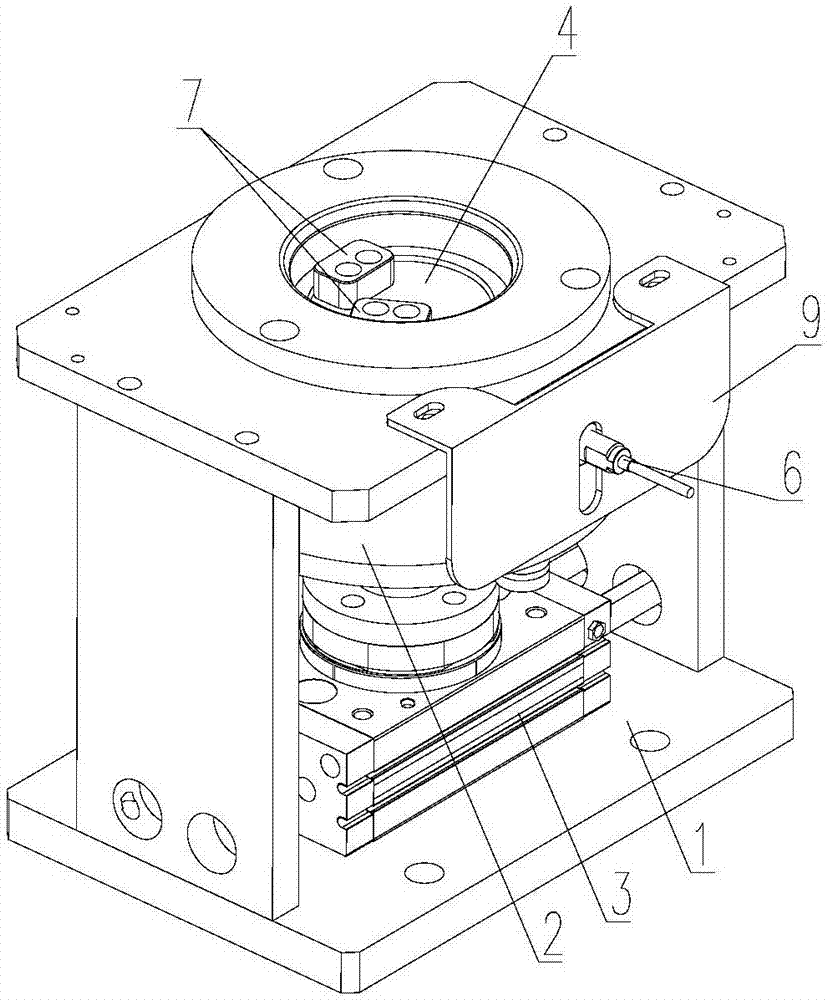

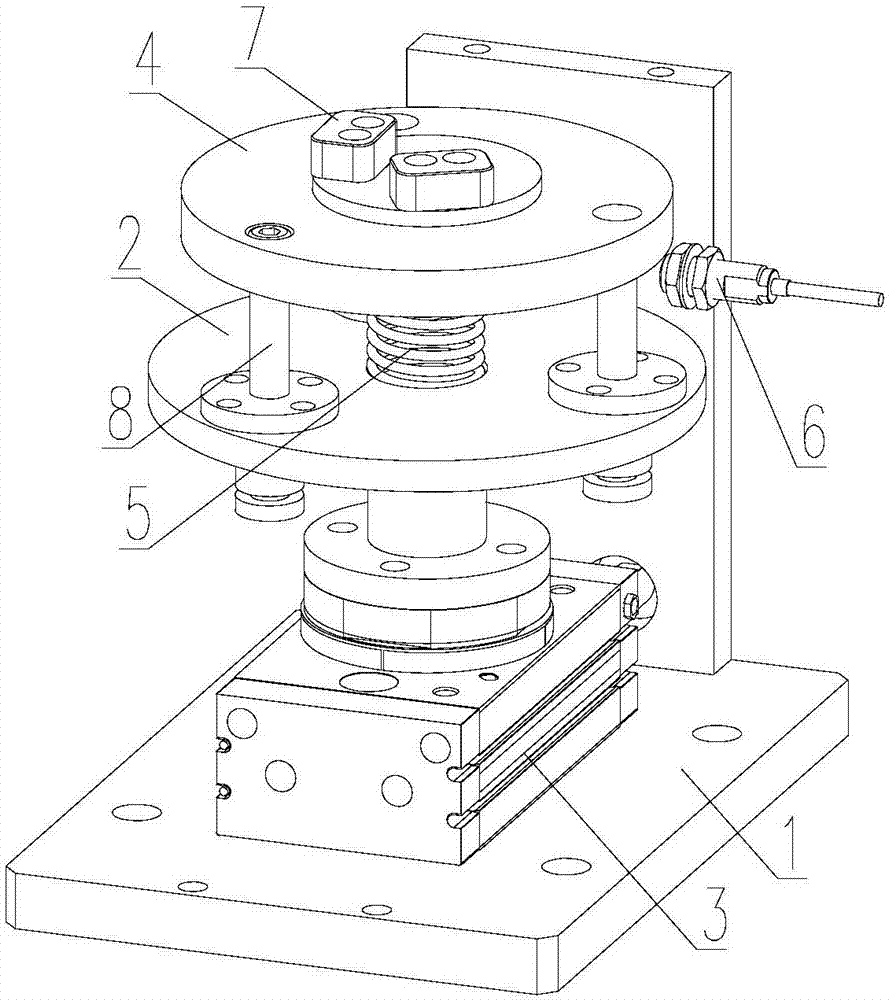

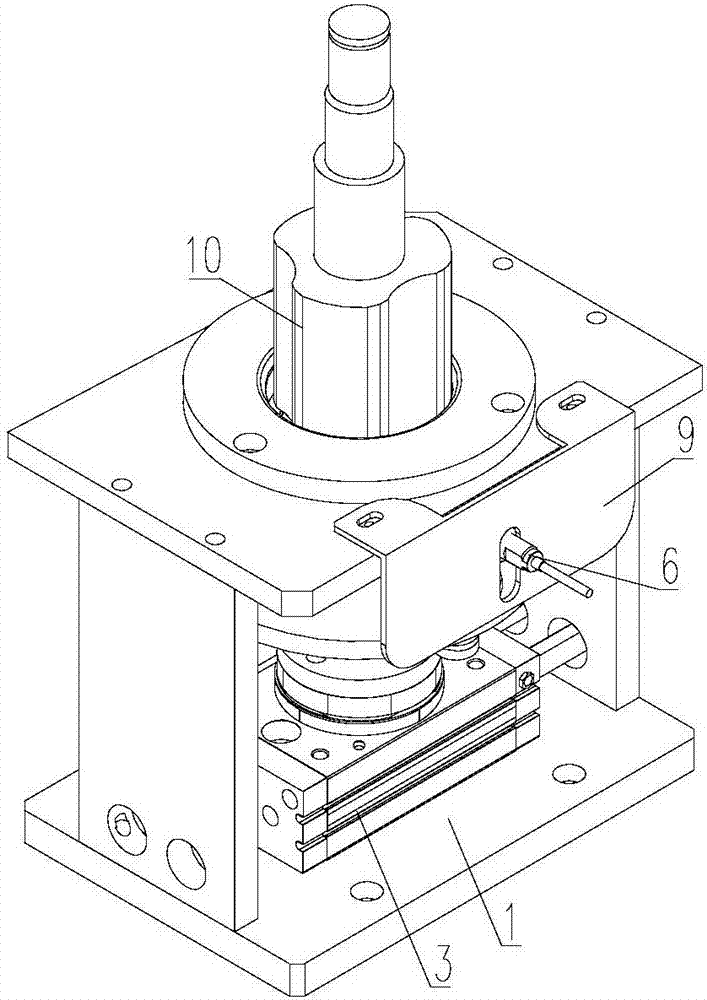

[0027] Such as Figure 1-5 As shown, a positioning mechanism for the machining of the three-pin shaft fork of the automobile transmission system, the bottom of the tripod shaft fork 10 has three axial holes 10-1 distributed along its circumferential direction, and the positioning mechanism includes:

[0028] base1;

[0029] A power mechanism 3, the power mechanism 3 is arranged on the base 1;

[0030] The fixed platform 2 is fixed on the output end of the power mechanism 3, and the power mechanism 3 is used to drive the fixed platform 2 to rotate;

[0031] The movable platform 4 is slidingly connected to the fixed platform 2 along its axial direction, the movable platform 4 is radially fixed relative to the fixed platform 2, a spring 5 is arranged between the movable platform 4 and the fixed platform 2, and at least One positioning block 7 matching the shaft hole 10-1 on the tripod shaft fork 10; it can also be two positioning blocks 7 on the movable platform 4 and matching ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com