Mechanism enabling wheels to steer in same direction and in inverse direction

A technology of steering mechanism and guiding mechanism, which is applied in the direction of steering mechanism, electric steering mechanism, steering rod, etc., and can solve the problems that the electric control motor steering system is difficult to adapt to the requirements, the steering is not flexible, vibration and high working pressure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

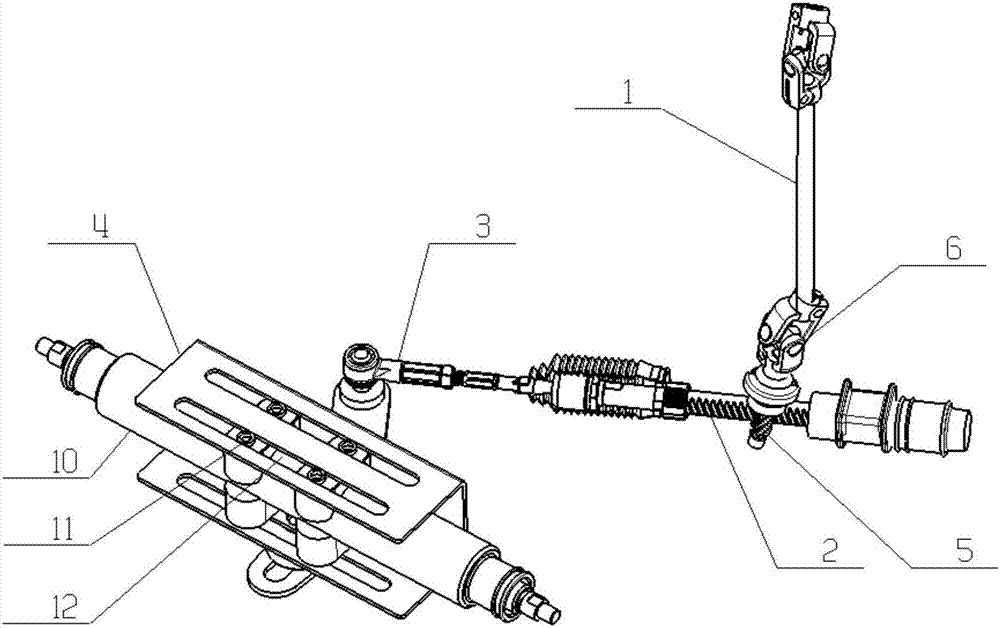

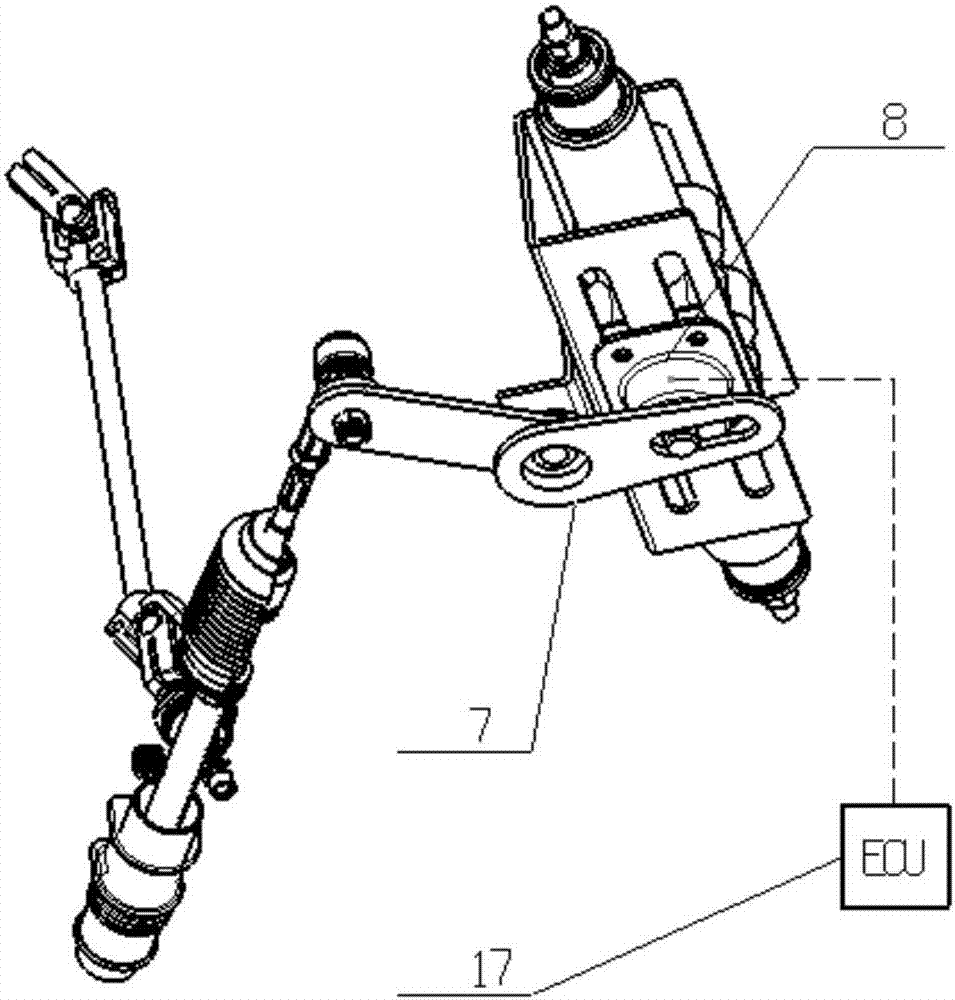

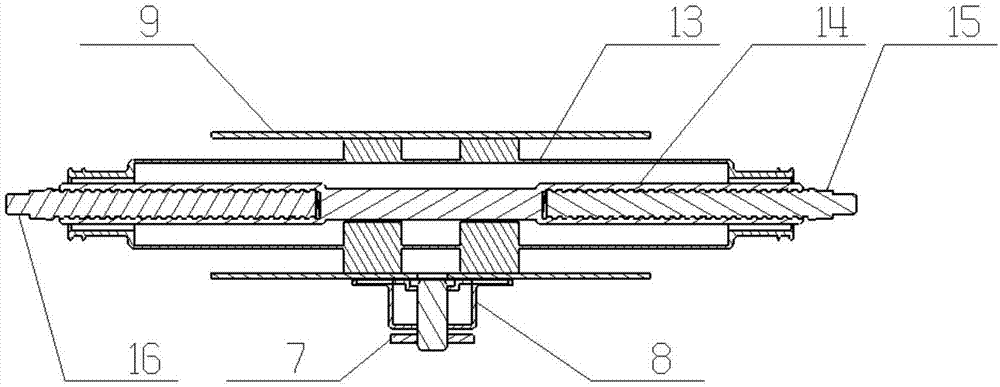

[0027] like Figure 1-3 As shown, the wheel co-directional and reverse steering mechanism has a mechanical steering unit, an electronic control unit and an execution unit; wherein, the electronic control unit includes a controller ECU 17; the mechanical steering unit includes a steering transmission shaft 1, a rack and pinion The transmission mechanism 2 and the slide bar guide mechanism 4, the steering transmission shaft 1 is connected with the helical gear 5 in the rack and pinion drive mechanism 2; one end of the rack and pinion drive mechanism 2 is connected with the slide bar guide mechanism 4 connection, such as figure 1 As shown; the execution unit includes a stepper motor 8 configured in the slide bar guide mechanism 4, the stepper motor 8 is connected with the controller ECU 17, and the stepper motor 8 is also connected with the slider The rod guide mechanism 4 is connected.

[0028] The slide rod guide mechanism 4 also includes a slide rod assembly 10, a fixed rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com