Automatic turnover device on production line of packaging machine

An automatic flipping and production line technology, applied in packaging automatic control, conveyor control devices, packaging, etc., can solve problems such as low production efficiency, troublesome product storage, and high labor intensity of workers, so as to improve production efficiency, facilitate transportation, Labor saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

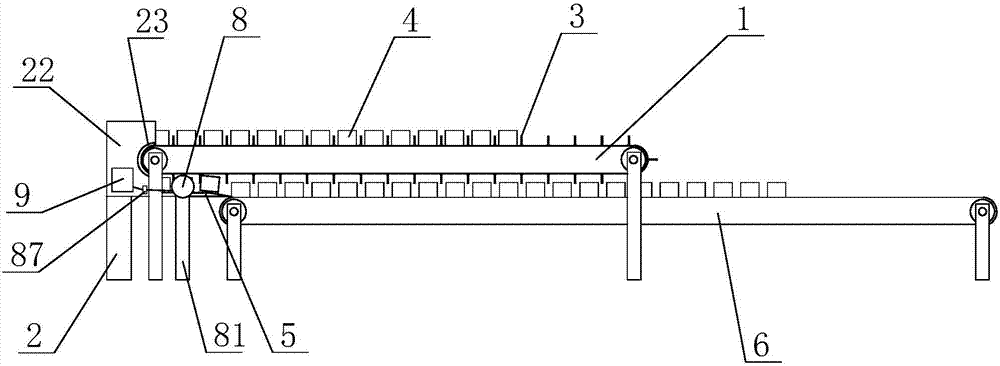

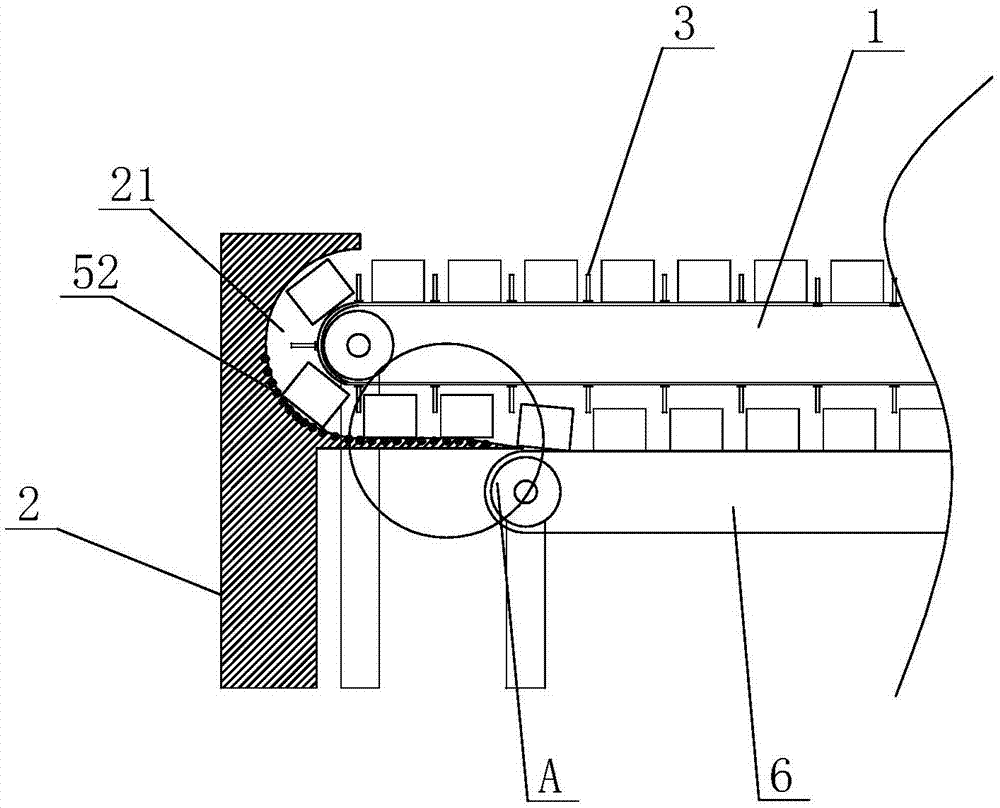

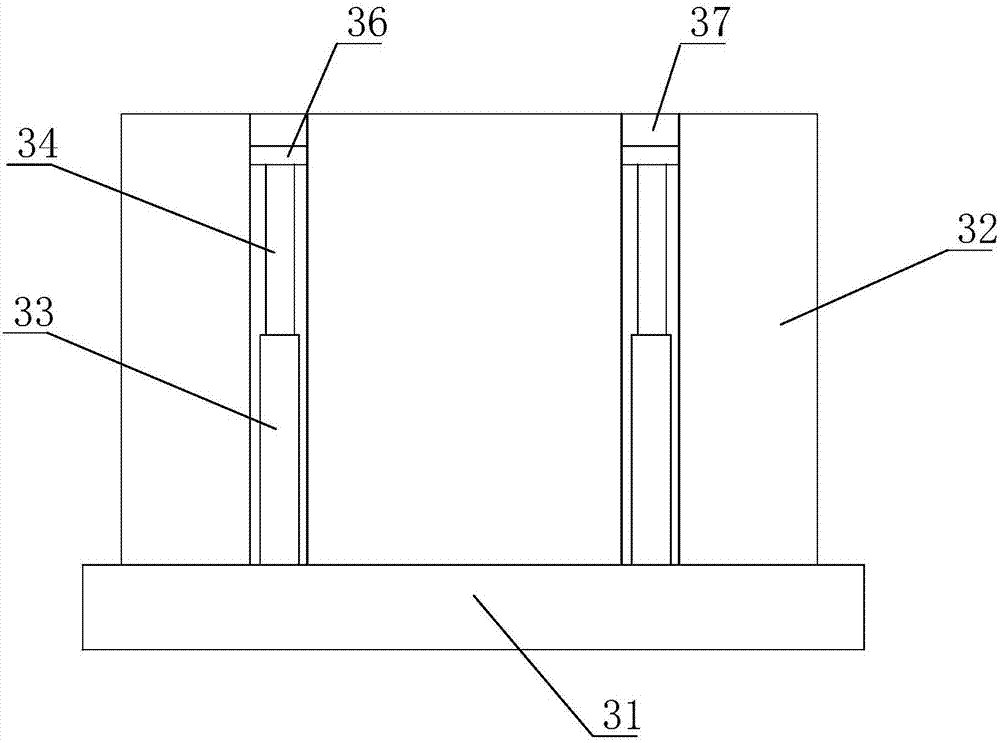

[0035] An automatic turning device for a packaging machine production line, comprising a first conveyor belt 1 and a stopper 2, the stopper 2 is provided with a semicircular arc-shaped groove 21, and both sides of the arc-shaped groove 21 are provided with baffles 22, The baffle plate 22 is provided with a second groove 23 adapted to the first conveyor belt 1, and several partitions 3 are arranged at equal intervals on the first conveyor belt 1, and the partitions 3 include a base 31 and a riser 32, The base 31 is fixedly connected with the first conveyor belt 1, the base 31 is provided with a first groove for installing the riser 32, and two fixing rods are arranged in the first groove, and the fixing rods include sleeves 33 and the inner rod 34 slidingly sleeved in the sleeve 33, the bottom end of the inner rod 34 is provided with a first spring 35, the other end of the first spring 35 is connected with the sleeve 33, the inner rod 34 The top stretches out from the sleeve pi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap