Spring type electric rail clamping device

A rail clamp, spring-type technology, applied in the direction of travel mechanism, load hanging element, transportation and packaging, can solve the problem of affecting the clamping performance of the rail clamp, unable to achieve the clamping effect, etc., to improve the heat dissipation effect, Good clamping rail effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

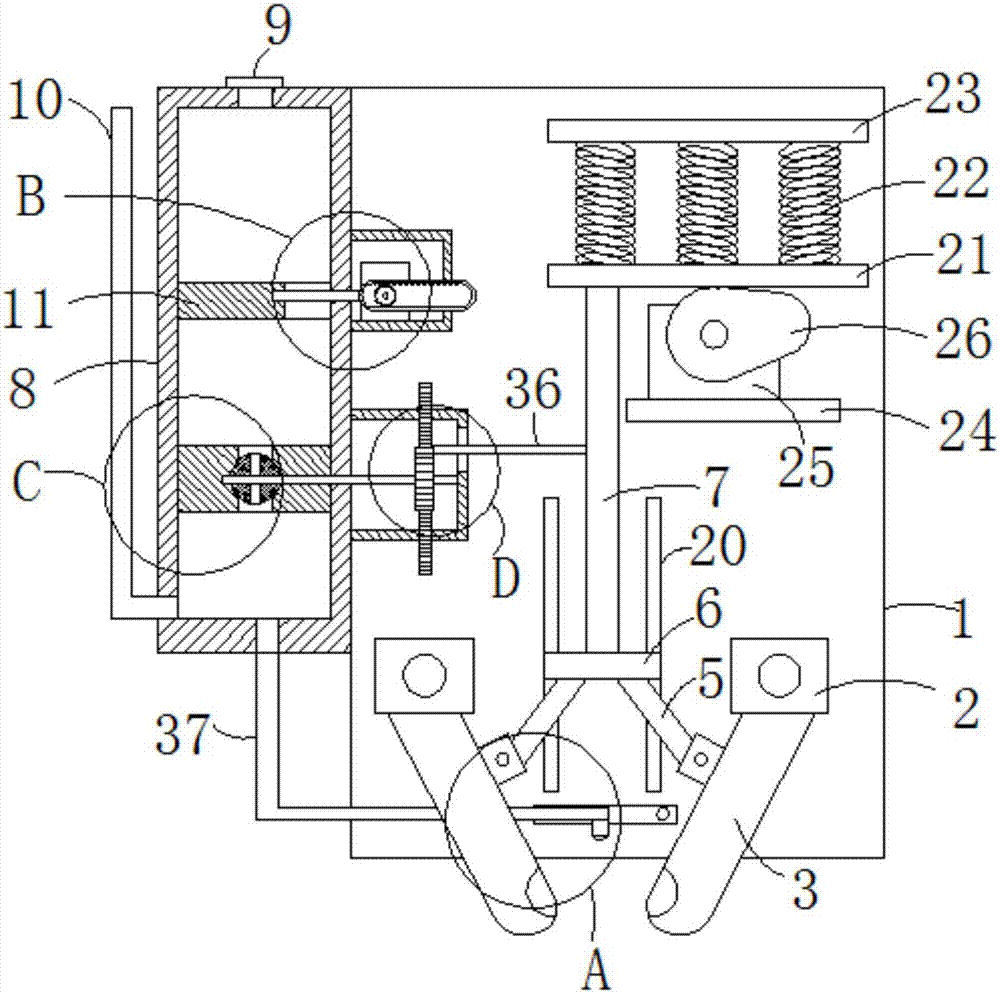

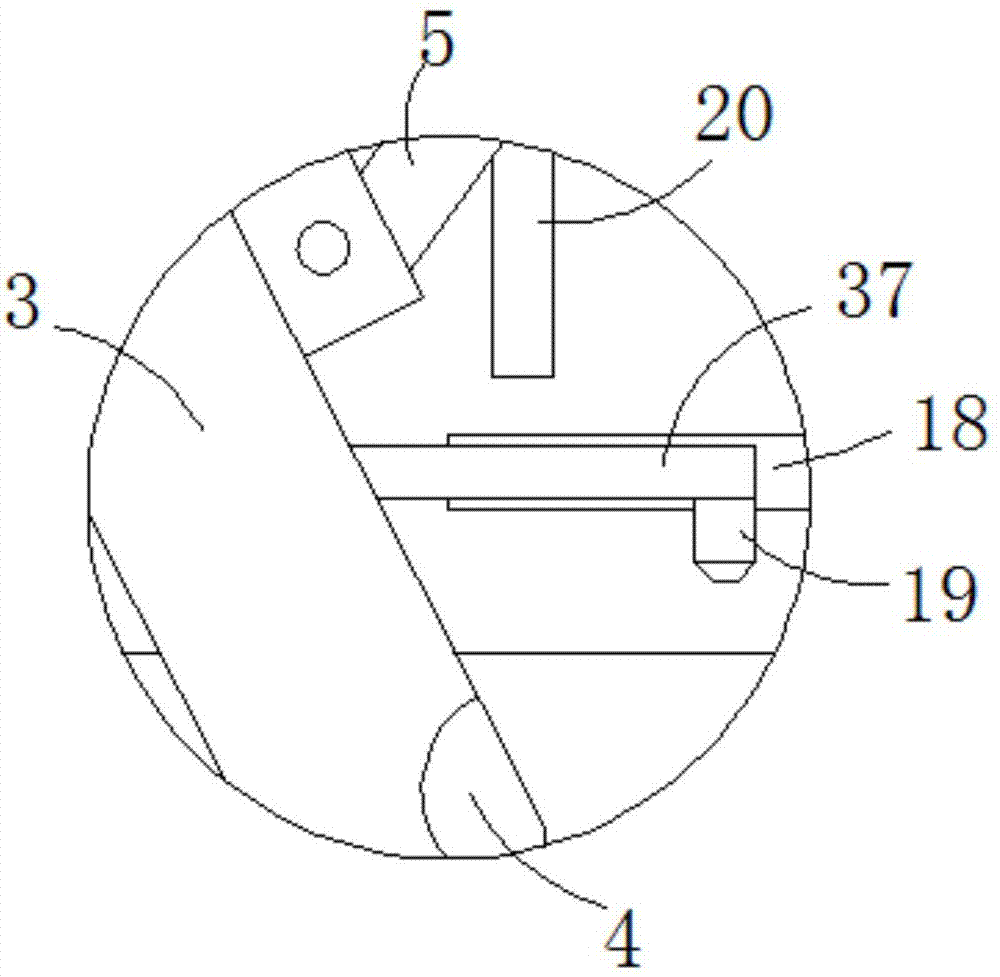

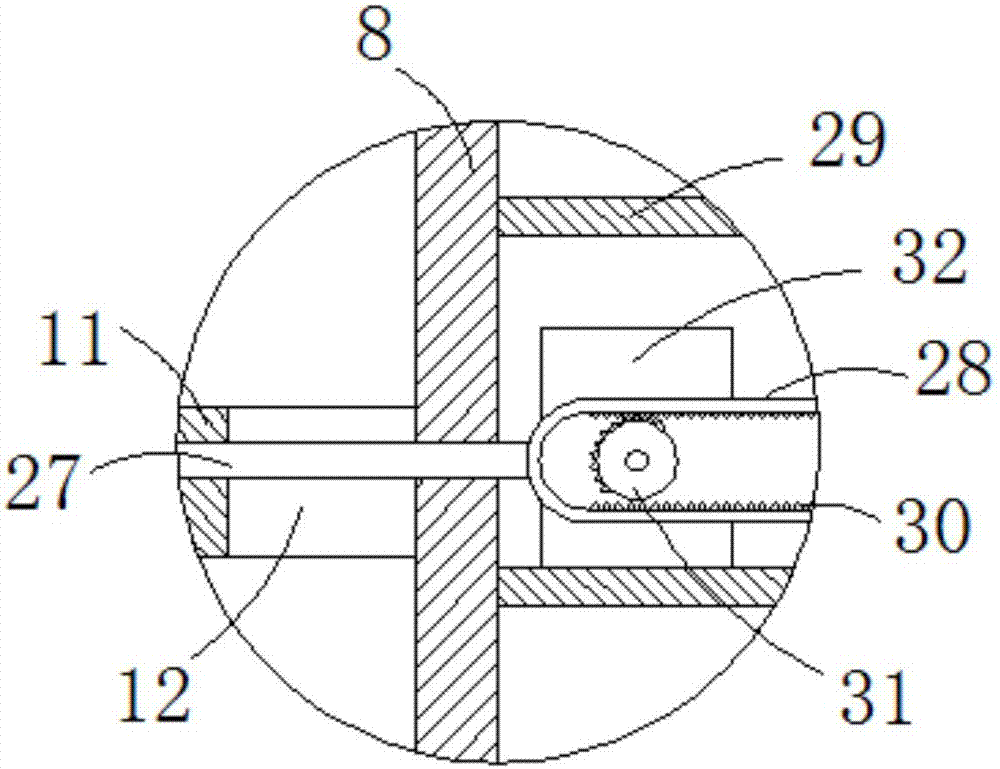

[0022] Such as Figure 1-5 As shown, a spring-type electric rail clamp includes a backboard 1, two fixed blocks 2 are fixedly connected to the side wall of the backboard 1, and the fixed block 2 is rotatably connected to a clamping plate 3, and the side of the clamping plate 3 The wall is provided with a clamping groove 4, specifically, the side walls of the clamping groove 4 are evenly distributed with protrusions, and the cross-section of the protrusions is triangular, which increases the roughness of the side walls of the clamping groove 4 and facilitates the clamping of the plate. 3 clamping track, the side wall of the clamping plate 3 is rotatably connected to the connecting rod 5, the upper end of the connecting rod 5 is fixedly connected to the middle plate 6, and the middle plate 6 is slidably connected to the side wall of the back plate 1, specifically, the back The side wall of the board 1 is provided with a chute 20, the side wall of the middle board 6 is fixedly co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com