Motor stator packaging mold

A technology of motor stator and mold, applied in the direction of manufacturing stator/rotor body, etc., can solve the problems of lack of reinforcement structure, separation of stator coils, complicated manufacturing process of motor stator, etc., to ensure consistency, ensure shape and position accuracy, and good heat dissipation. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the purpose and features of the present invention more comprehensible, the specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings. The drawings in the following description are merely drawings of some embodiments of the invention. For those skilled in the art, other implementation manners can also be obtained based on these implementation manners without any creative efforts.

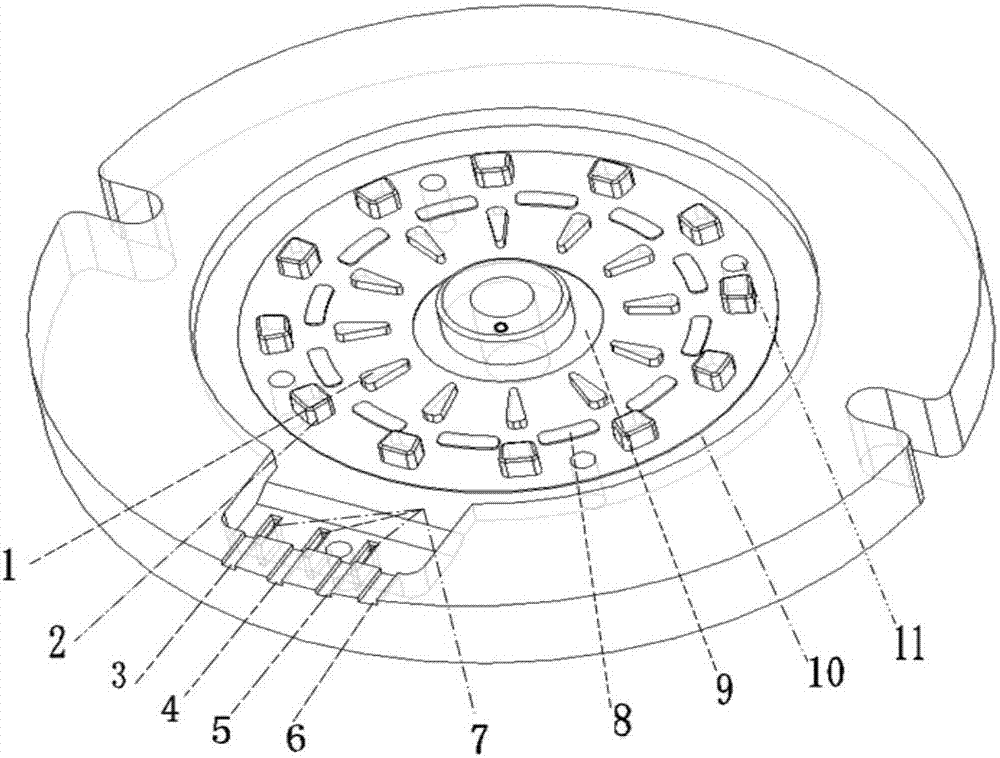

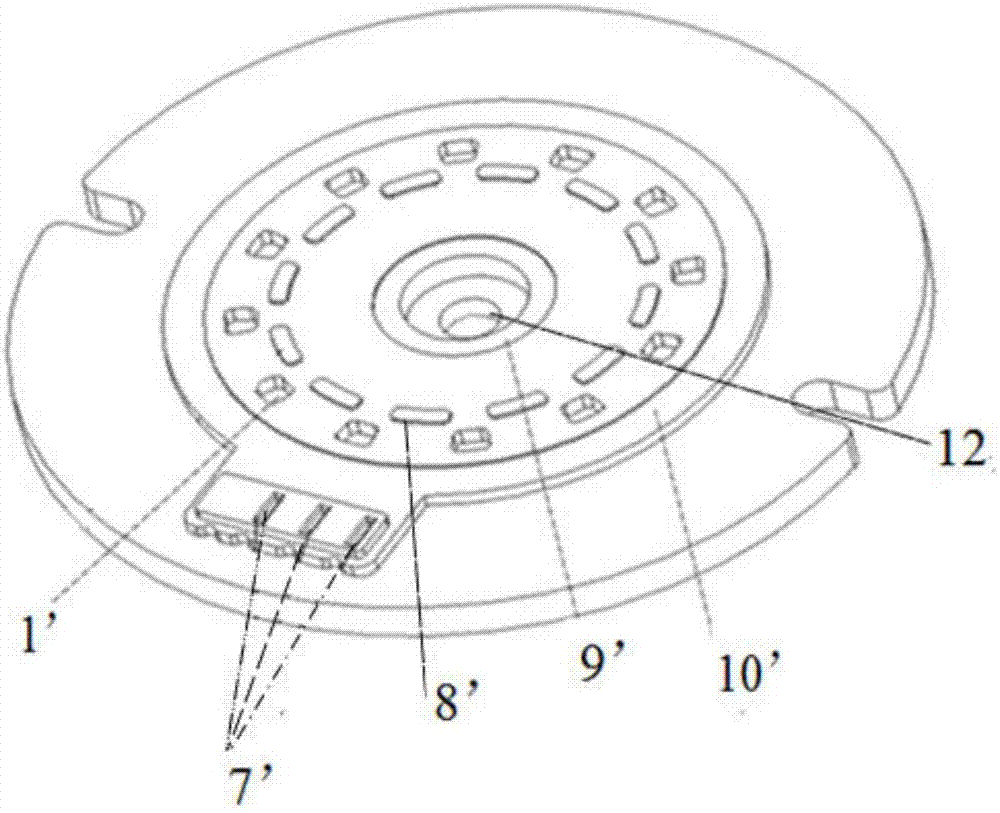

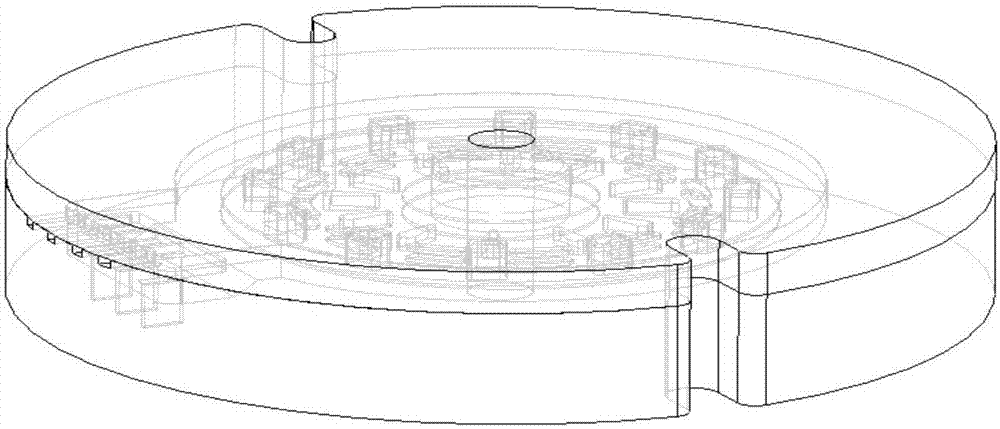

[0020] figure 1 Shown is a schematic diagram of the lower mold of the motor stator packaging mold disclosed in this embodiment, including: twelve inner positioning columns arranged in a uniform ring shape, and outer positioning columns arranged in a uniform ring shape on the outer ring that are equal in number to the inner positioning columns. There are three lead-out notches, one connecting-end notch, a notch for placing a word piece, and a post hole for the ejector rod. The lower mold is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com