Highland barley roasting machine achieving uniform roasting

A roasting and frying machine, uniform technology, applied in application, food processing, food science, etc., can solve the problems of high consumption and low output, complex process, ecological environment damage, etc., and achieve the effect of reasonable structure, high efficiency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

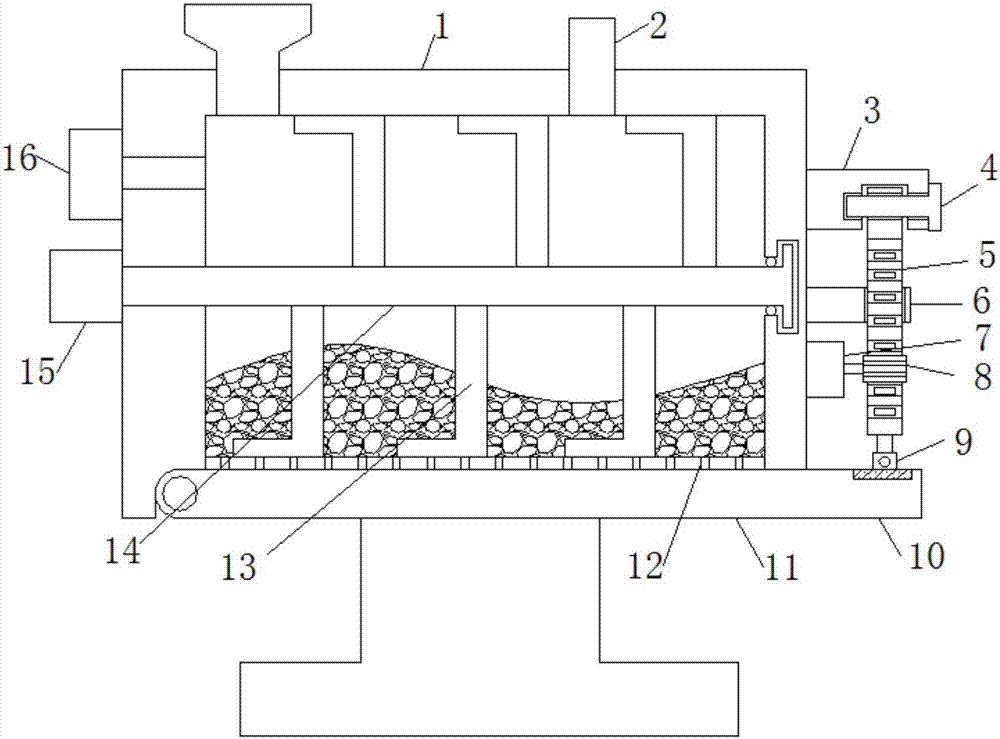

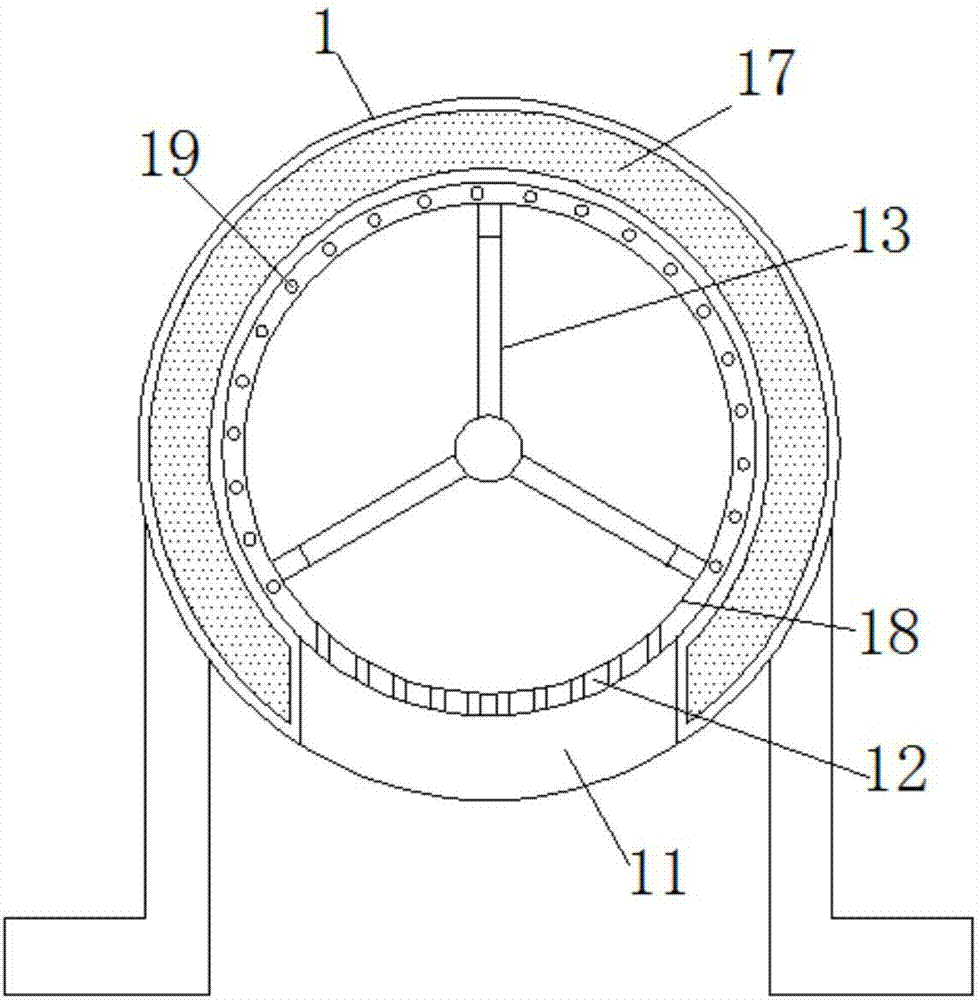

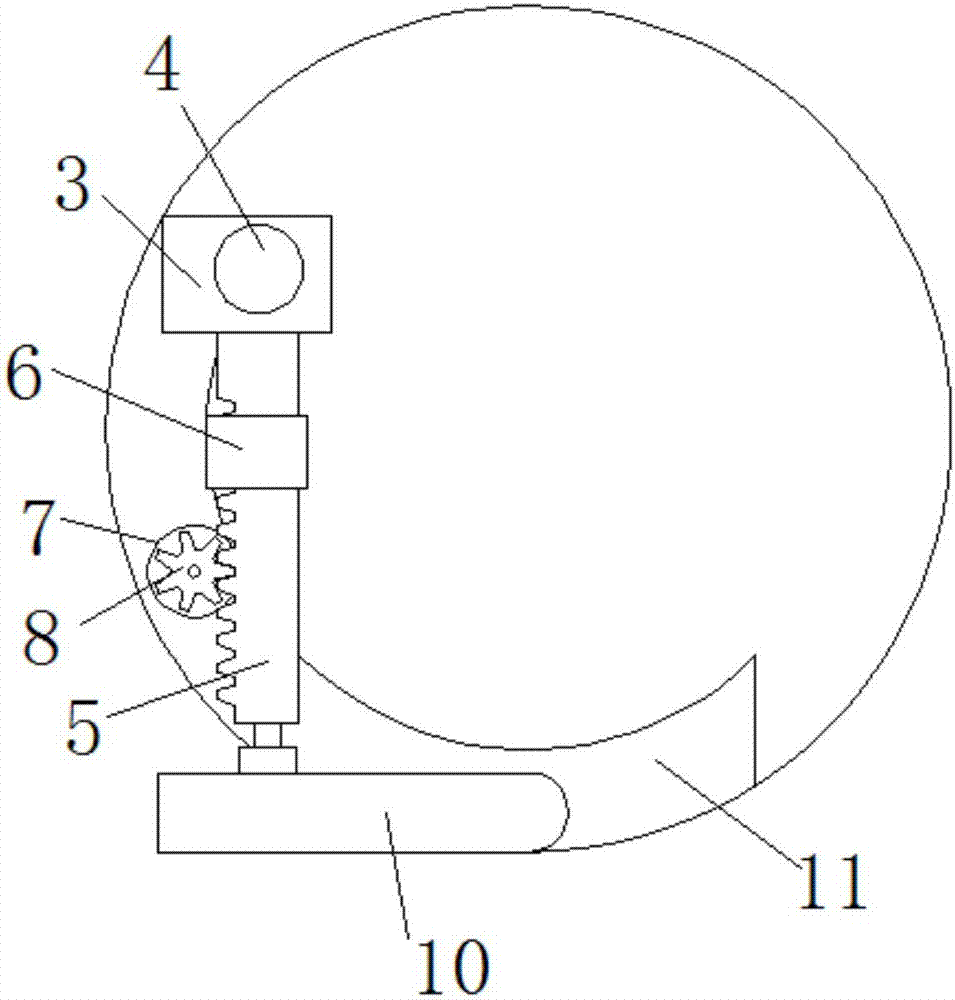

[0017] refer to Figure 1-3 , a highland barley roasting machine for uniform roasting, comprising a roasting box cover 1, the roasting box cover 1 is a double-layer structure, small particles of heat-preserving limestone 17 are filled between the roasting box covers 1, and the roasting box cover 1 The inner ring is fixed with a heating plate 18, a plurality of electric heating rods 19 are installed inside the heating plate 18, a screen 12 is installed at the bottom of the heating plate 18, a holding plate 11 is installed at the bottom of the screen 12, and the frying box The both sides of outer cover 1 are all fixed with shroud, and one end of holding board 11 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com