Multifunctional tea leaf frying machine

A multi-functional tea frying machine and tea frying technology, which is applied in tea processing before extraction, etc., can solve the problems of not being able to adapt to large-scale operations and high-efficiency tea production, wasting energy by using electricity, and occupying a large space, etc., to achieve frying High manufacturing efficiency, high space utilization, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

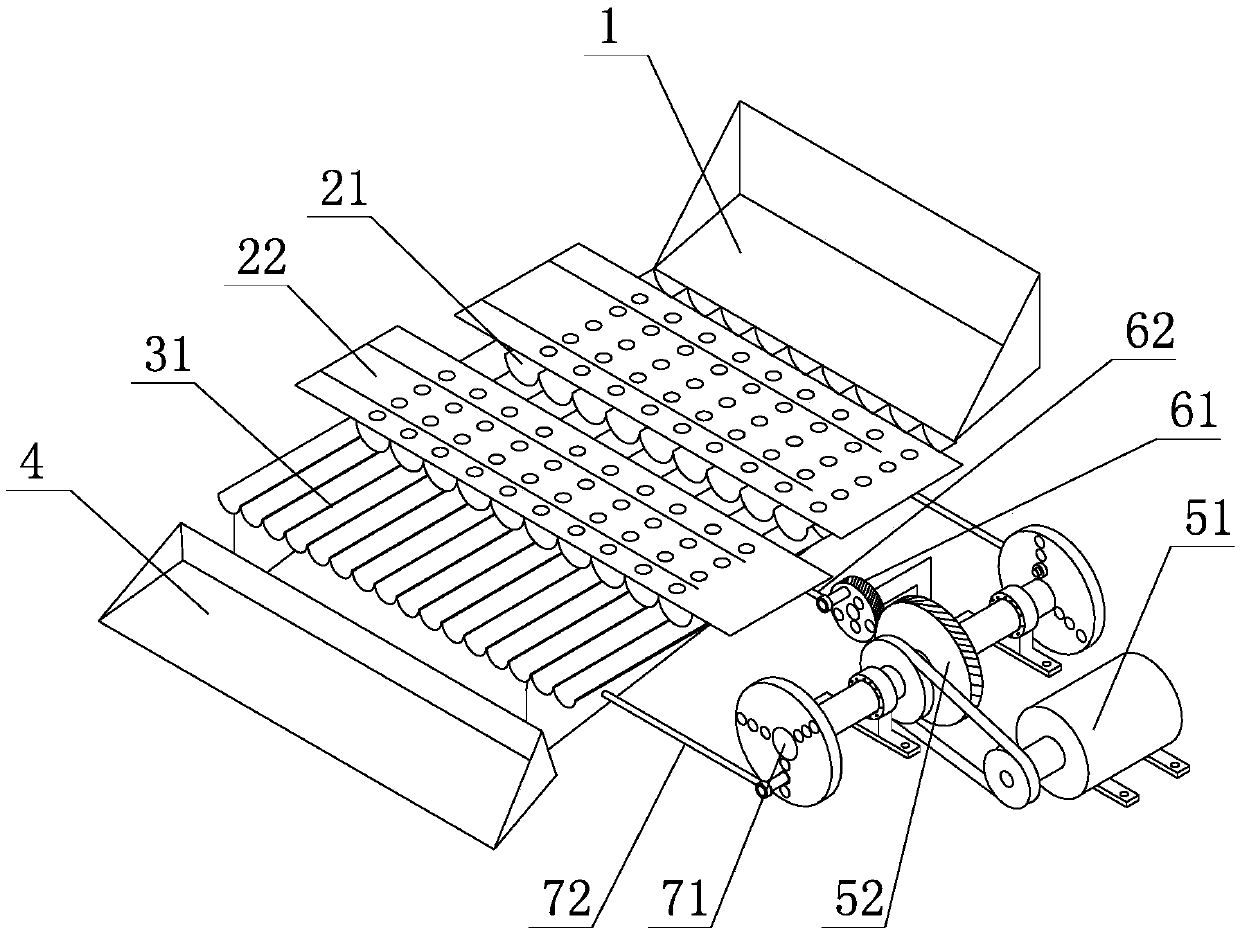

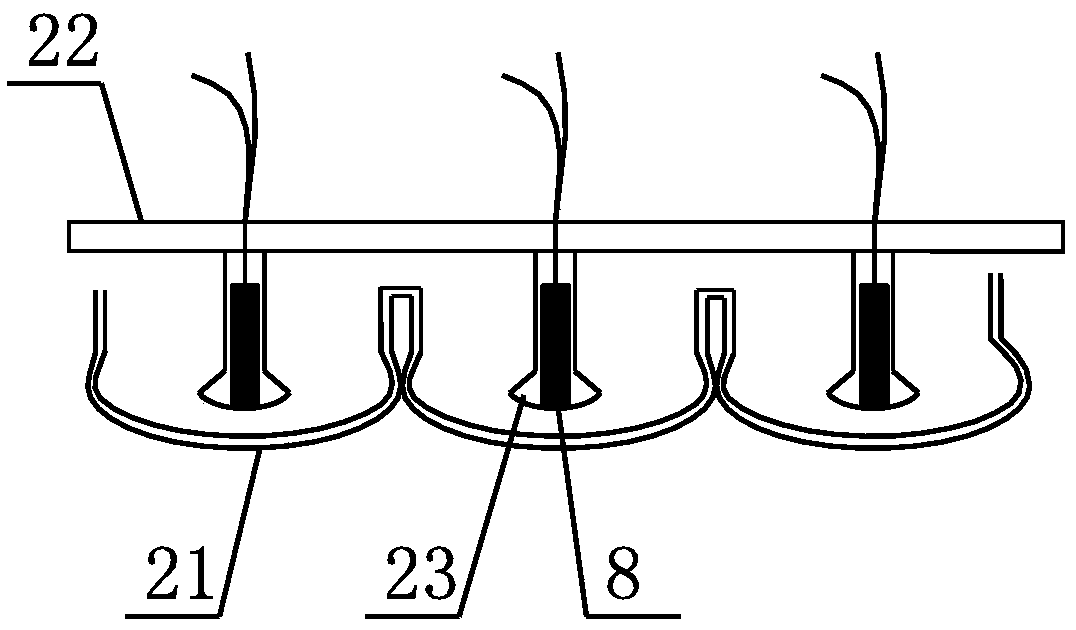

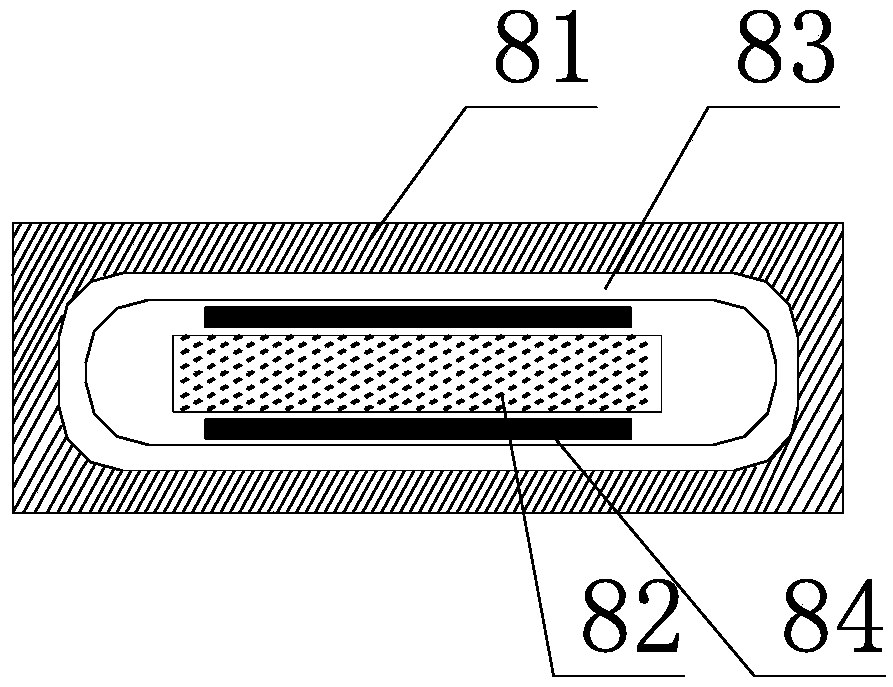

[0020] Such as Figures 1 to 3 as shown, figure 1 It is a structural schematic diagram of a multifunctional tea frying machine proposed by the present invention, figure 2 for figure 1 Schematic diagram of the structure of the fried tea unit, image 3 for figure 2 Schematic diagram of the structure of the PTC heater.

[0021] refer to Figures 1 to 3 , a kind of multifunctional tea frying machine that the present invention proposes, comprises: frame, feed mechanism 1, fry tea mechanism, strip mechanism, discharge mechanism 4, power mechanism;

[0022] The feeding mechanism 1, the tea-frying mechanism, the stripping mechanism, and the discharging mechanism 4 are sequentially arranged on the frame, the feeding mechanism 1 is connected with the feeding end of the tea-frying mechanism, and the stripping mechanism includes a stripping bin 31 and a first driving mechanism , the first driving mechanism is connected with the strip bin 31 to drive the strip bin 31 to reciprocate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com