Active Dual Cycle Exhaust Shoes

A dual-cycle, active technology, applied to footwear, shoe soles, clothing, etc., can solve the problems of small flow, weak strength, and difficulty in discharging a large amount of sewage from shoe cavities, and achieve the effect of improving sewage discharge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

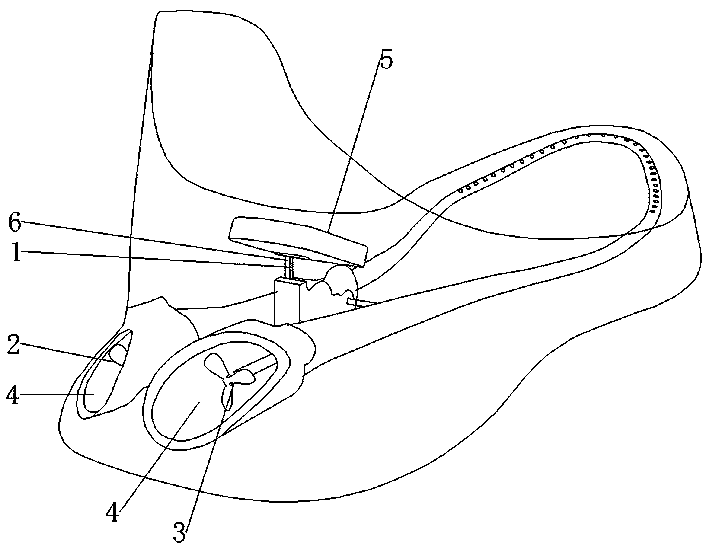

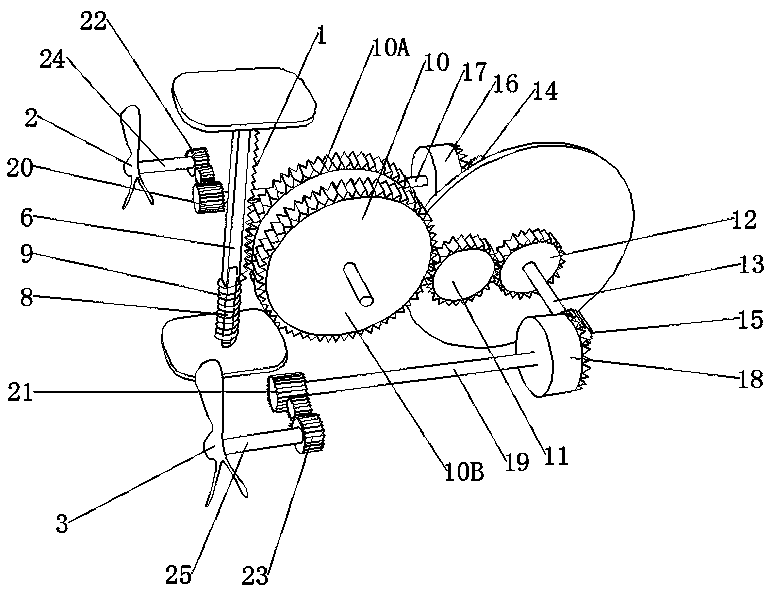

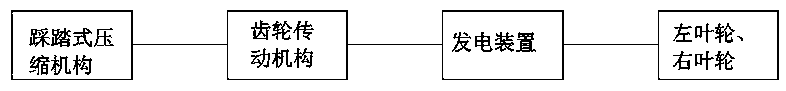

[0011] refer to figure 1 , figure 2 As shown, the active dual-cycle exhaust shoe provided by the first embodiment of the present invention includes a sole, and a pedal-type compression mechanism that can be compressed and reset is provided at the heel of the sole. The pedal-type compression mechanism is equipped with a rack 1, and The bar 1 generates energy to drive the left impeller 2 and the right impeller 3 through the gear transmission mechanism. In this embodiment, the rack 1 is respectively connected with the left impeller 2 and the right impeller 3 on both sides through the gear transmission mechanism. Both sides are provided with a through hole 4 towards the rear, and the through hole 4 communicates with the air vent at the forefoot of the sole through the internal flow channel, and the left impeller 2 and the right impeller 3 are respectively arranged at the outlet of the through hole 4 , the driving direction of the left impeller 2 and the right impeller 3 is alway...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com