Breathable carbon rods and preparing method thereof

A carbon rod and semi-finished product technology, applied in the field of breathable carbon rods and their preparation, can solve the problems of hidden safety hazards in production, low carbon rod ventilation, poor discharge performance, etc. hidden effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

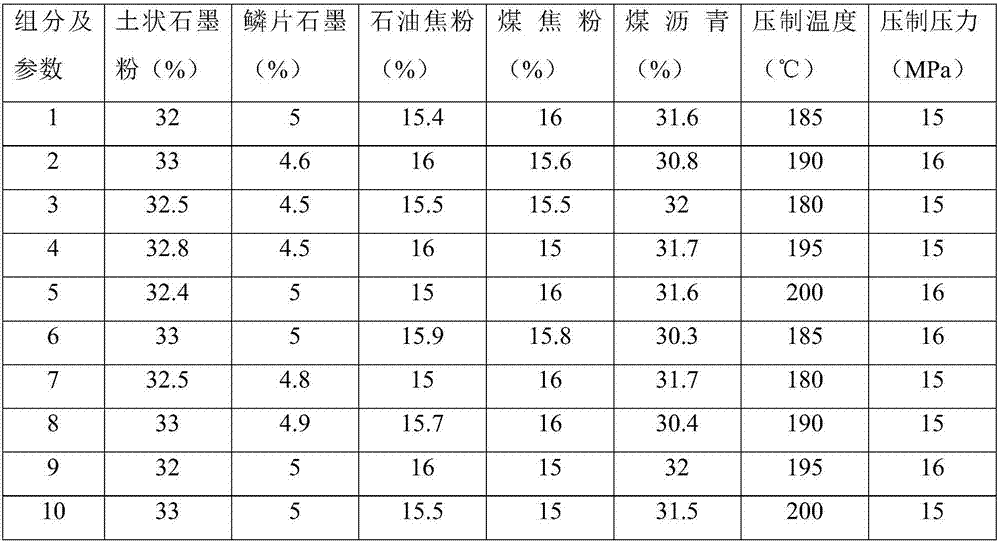

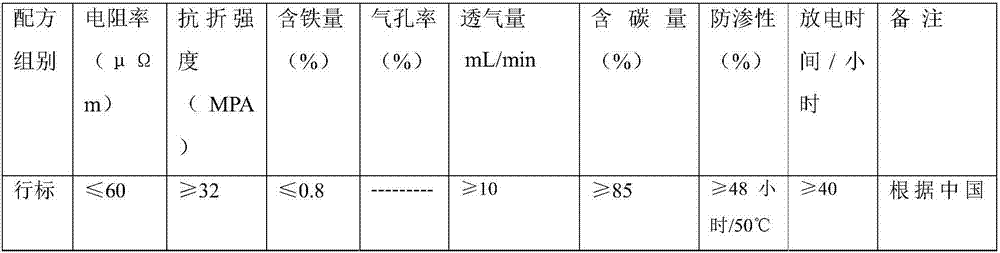

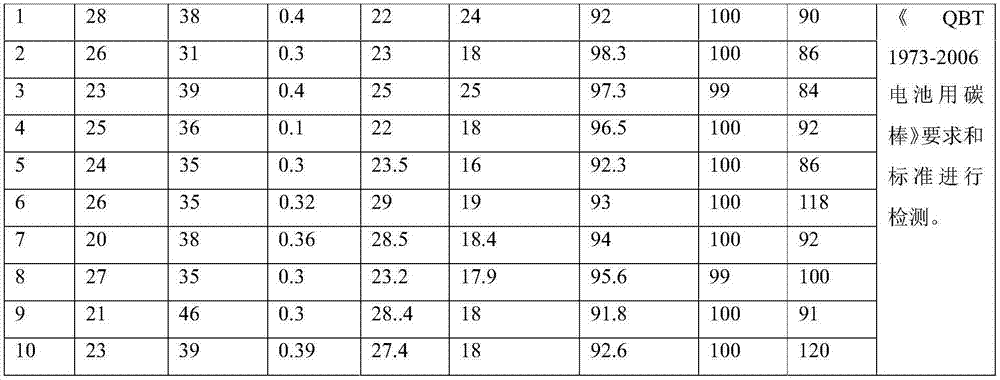

[0026] Table 1 shows the raw materials used for the gas-permeable carbon rod of the present invention.

[0027] Table 1 Raw materials and main process parameters used in the breathable carbon rod of the present invention

[0028]

[0029] The preparation method of the breathable carbon rod of the present invention includes the following steps:

[0030] (1) Mix earthy graphite powder, flake graphite, petroleum coke powder, and petroleum pitch with a softening point of 80°C at 160-170°C for 1 hour to make a mixed paste;

[0031] (2) Heat the mixed paste to 180-200°C for pressing, and control the pressure in the pressing process to 15-16 MPa to obtain a rough carbon strip;

[0032] (3) The rough carbon strip is first heated to 200°C for drying and dehydration, then to 700°C for crude oil drainage, then to 900°C for concentrated oil drainage, and finally to 1200°C for polymerization carbonization;

[0033] (5) Grind the carbonized rough carbon rod into a cylindrical carbon rod of 8mm×57mm to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com