Front half section assembly device for stop valve

A technology of assembling device and globe valve, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problem of large fluctuation of product quality, and achieve the effect of reducing production cost and saving human resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

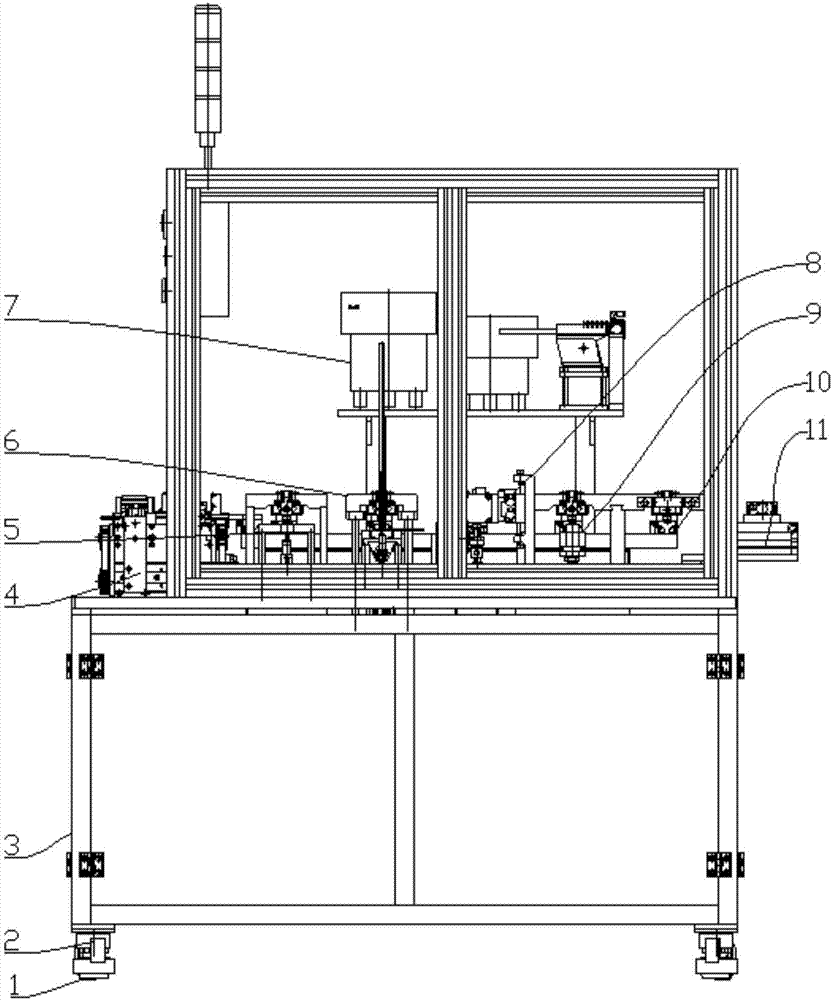

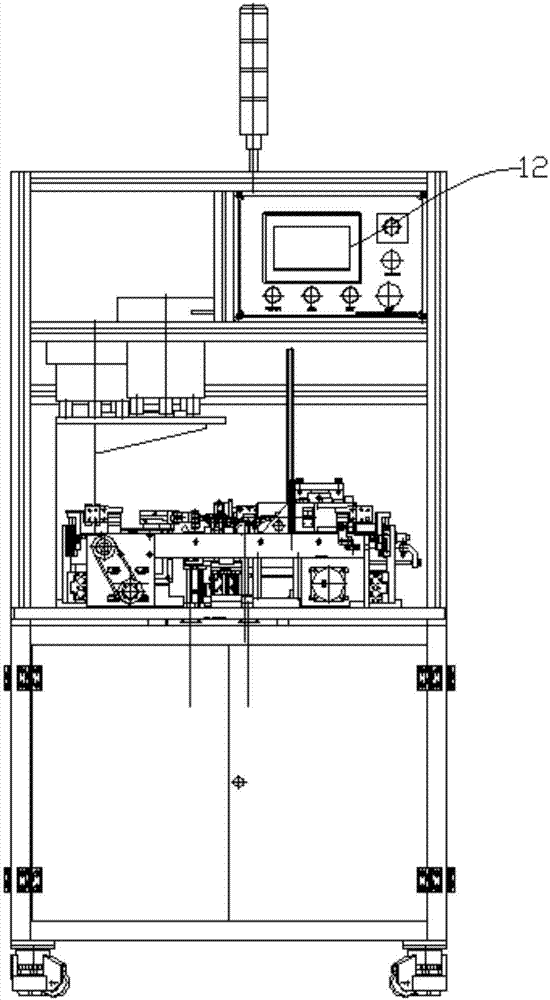

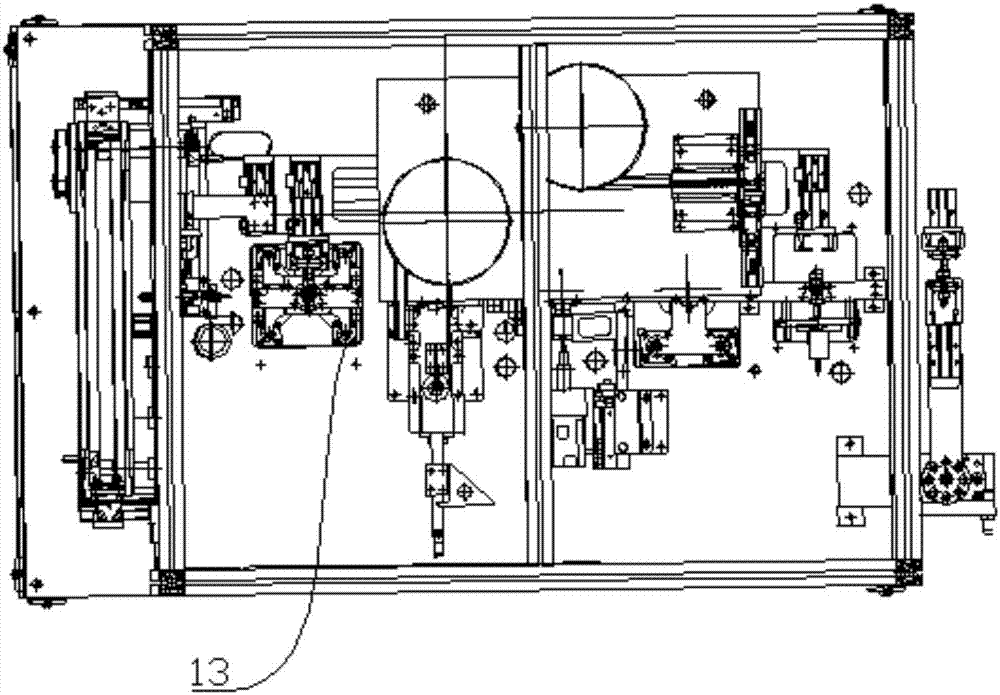

[0021] Such as Figure 1-Figure 3 As shown, an assembly device for the first half of a stop valve includes a bottom moving roller 1, a raw material placement table 4, an automatic valve core tightener 8 and an operation control panel 12. A roller fixing bracket 2 is installed above the bottom moving roller 1, and the roller is fixed The main support frame 3 is installed above the support frame 3, and the raw material placement platform 4 is installed above the main support frame 3. The automatic tightening valve stem 5 is installed on the right side of the raw material placement platform 4, and the automatic ring loading device 6 is installed on the right side of the automatic tightening valve stem 5. , a servo drive motor 7 is installed above the automatic coiler 6, an automatic valve core tightener 8 is connected to the bottom of the servo drive motor 7, an automatic neck...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com