Using method of dismounting device special for vehicle transmission bearings

A technology of automobile gearbox and disassembly device, which is applied to hand-held tools, manufacturing tools, etc., can solve the problems of low work efficiency, damaged parts, time-consuming and laborious, etc., so as to reduce labor intensity, reduce maintenance time, and reduce disassembly procedures. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

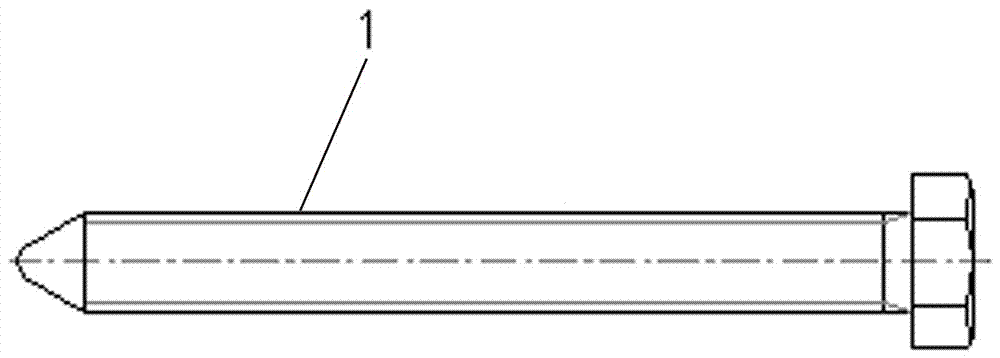

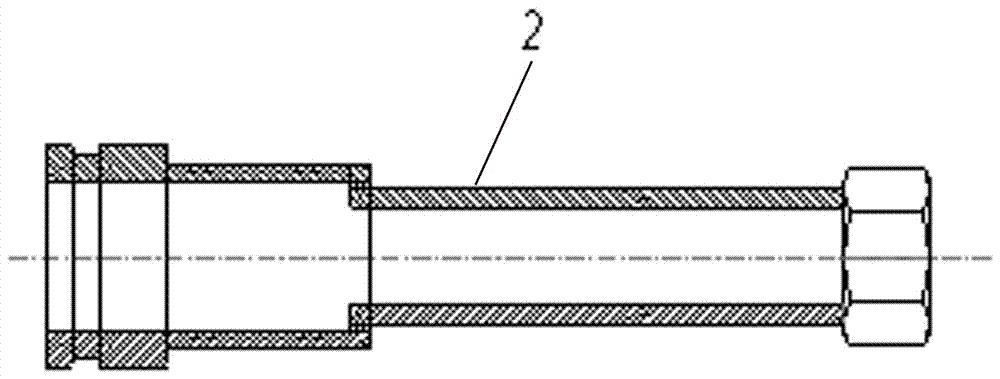

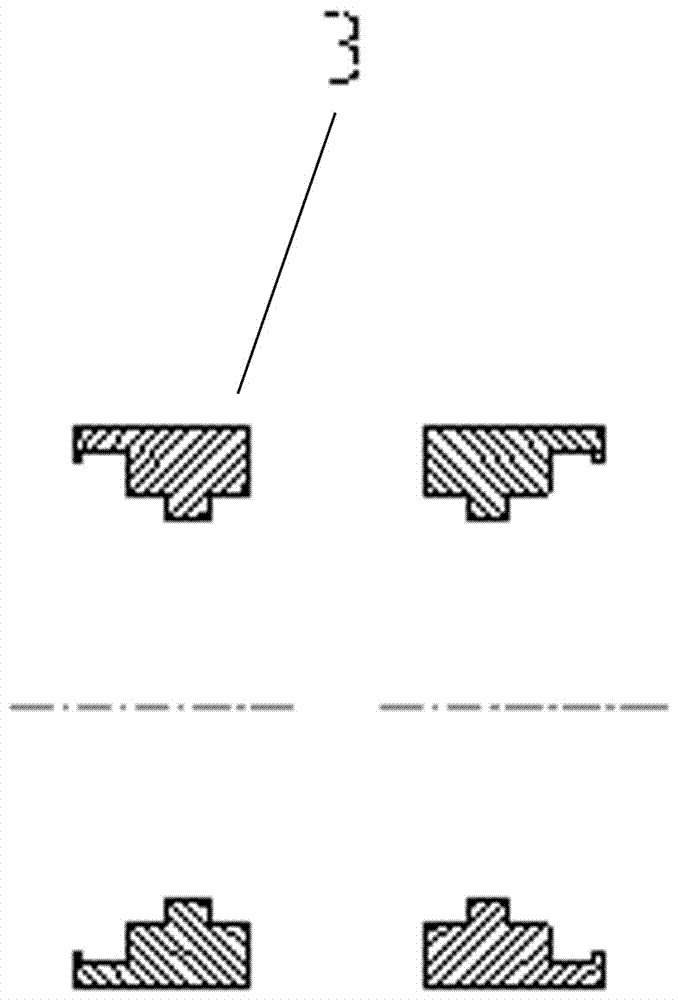

[0029] see Figure 1 to Figure 6 , a special disassembly device for automobile gearbox bearings, consisting of a conical ejector rod 1, an M33 nut, a puller 2, a split pull block 3 and a pull block clamp 4; the method of using the special disassembly device for automobile gearbox bearings, its The steps are:

[0030] Step 1: Align the puller 2 with the fixed shaft where the bearing 6 is to be disassembled;

[0031] Step 2: Put the end of the pulling tube 2 on the fixed shaft end of the bearing 6 to be disassembled;

[0032] Step 3: According to the different specifications of the bearing 6, select the corresponding semi-circular split pull block 3, clamp the radial end of the semi-circular split pull block 3 in the stop groove of the outer ring of the bearing 6, and clamp the other end in the pull tube 2 In the groove, the two pull blocks are closed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com