Forming mold for HDPE double-wall corrugated pipes

A double-wall corrugated pipe, forming mold technology, applied in household appliances, tubular items, other household appliances, etc., can solve the problems of insufficient melt plasticization of raw materials, unstable product quality, product quality dependence, etc. Benefit and economic benefit, improve production stability, avoid the effect of manual adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

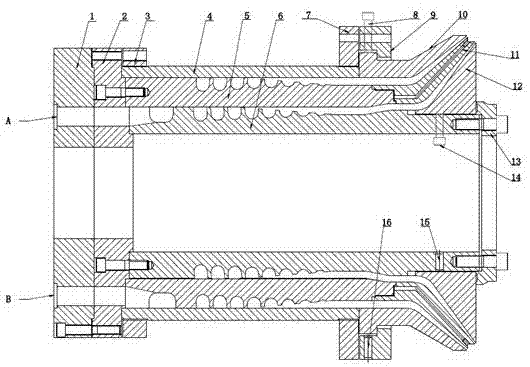

[0024] Such as figure 1 Shown is that the first embodiment of the HDPE double-wall corrugated pipe forming die of the present invention includes the inner and outer wall forming die body, the inner and outer wall forming die body includes the outer die body 4, the outer layer spiral body 5 and the inner layer spiral body 6, the outer die body 4 and the inner layer spiral body 6 The outer spiral body 5 forms the first outer wall material channel through which the outer layer melt flows, and the outer layer spiral body 5 and the inner layer spiral body 6 form the first inner wall material channel through which the inner layer melt flows. Specifically, both the first outer wall material channel and the first inner wall material channel are spiral structures with continuously decreasing spiral radius, the outer layer melt moves axially in the first outer wall material channel, and the inner layer melt moves in the first inner wall Axial spiral movement is made in the material chan...

Embodiment 2

[0027] Such as figure 1 The second embodiment of the molding die for the HDPE double-wall corrugated pipe shown includes the inner and outer wall forming dies, and the inner and outer wall forming dies include the outer layer die heat adjustment mechanism, the inner layer die heat adjustment mechanism and the die splitter core 11 , between the outer layer die heat regulating mechanism and the die splitting core 11, and between the inner die adjusting mechanism and the die splitting core 11, melt flow channels are formed. Specifically, the outer layer die heat adjustment mechanism includes an outer layer die 10, an outer layer die pressing plate 9, an outer layer die flange 7 and an outer layer thermal expansion screw 8 arranged on the outer layer die flange 7, and the inner layer The die heat regulating mechanism includes an inner die 12 , an inner die pressing plate 13 and an inner thermal expansion screw 14 arranged on the inner spiral body 6 .

[0028] Among them, such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com