Full-automatic winding machine and application method thereof

A fully automatic, rolling machine technology, applied in the direction of winding strips, thin material processing, transportation and packaging, etc., can solve the problems of discontinuous operation of equipment, excessively large winding tape, inconvenient production and sales, etc., to avoid long-term Time downtime, improve production efficiency, and avoid the effect of tape falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

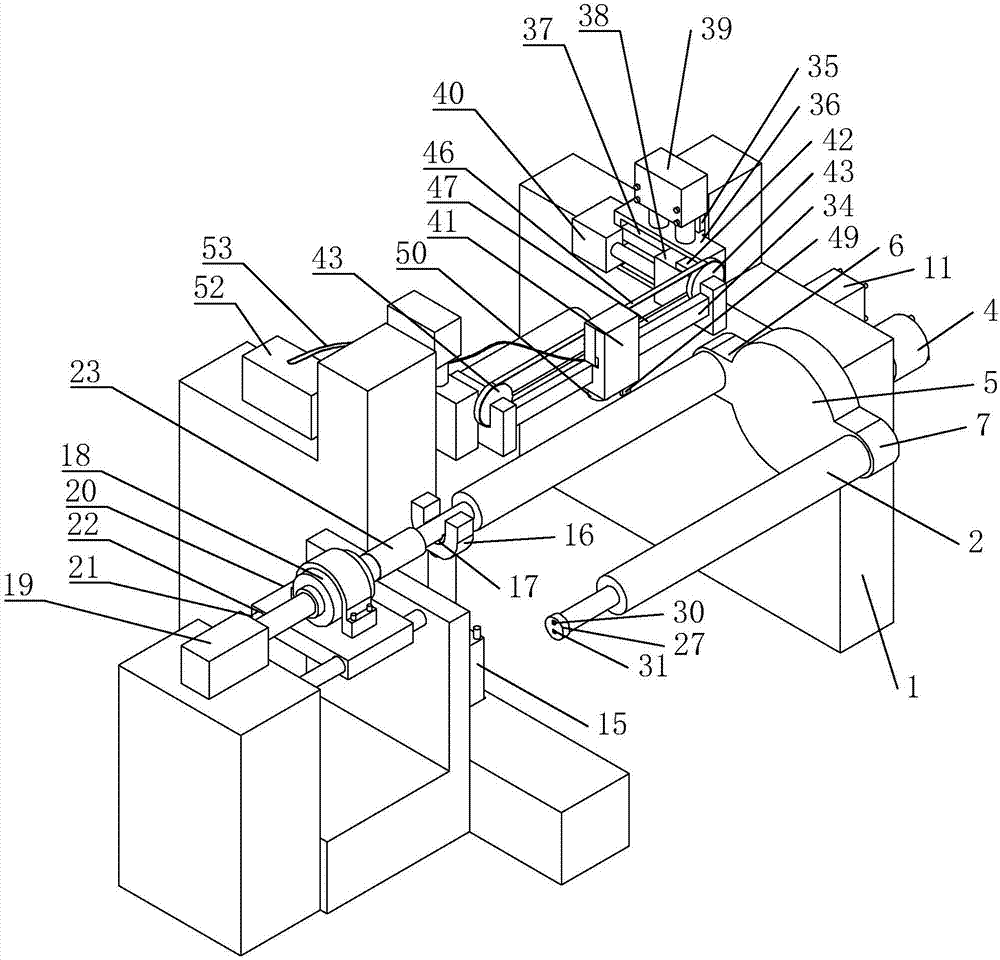

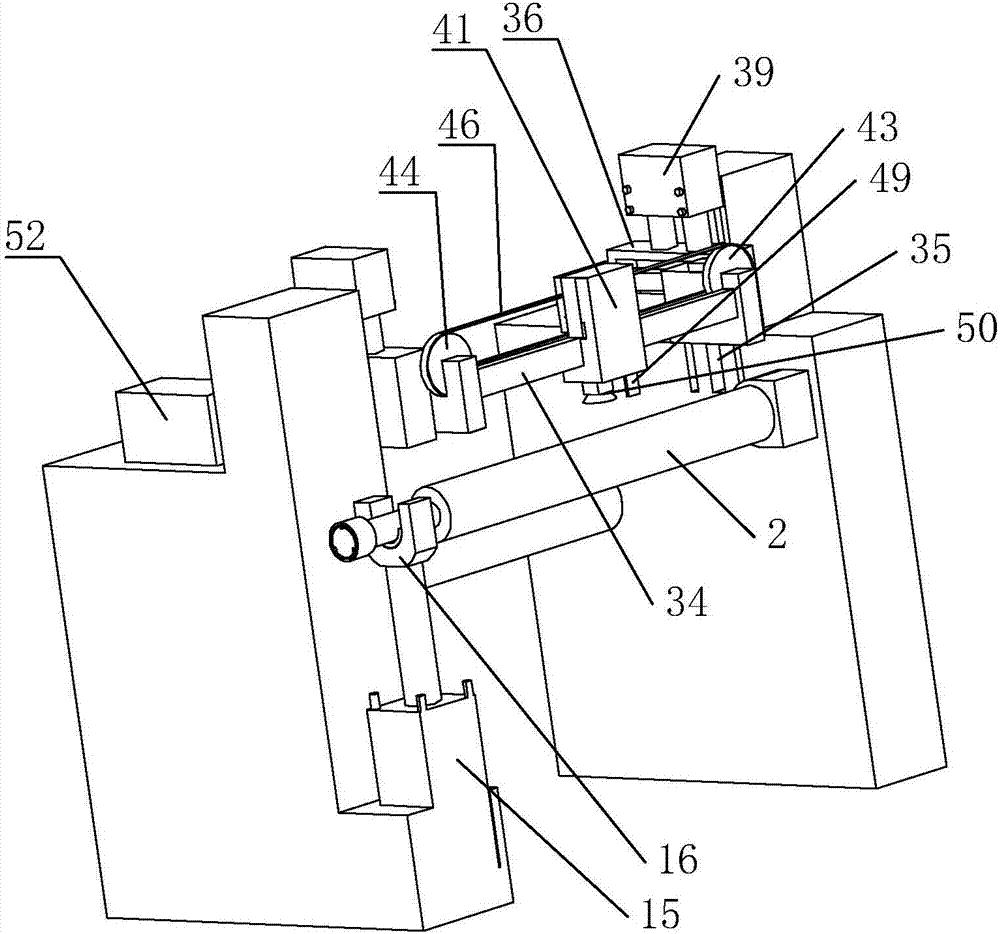

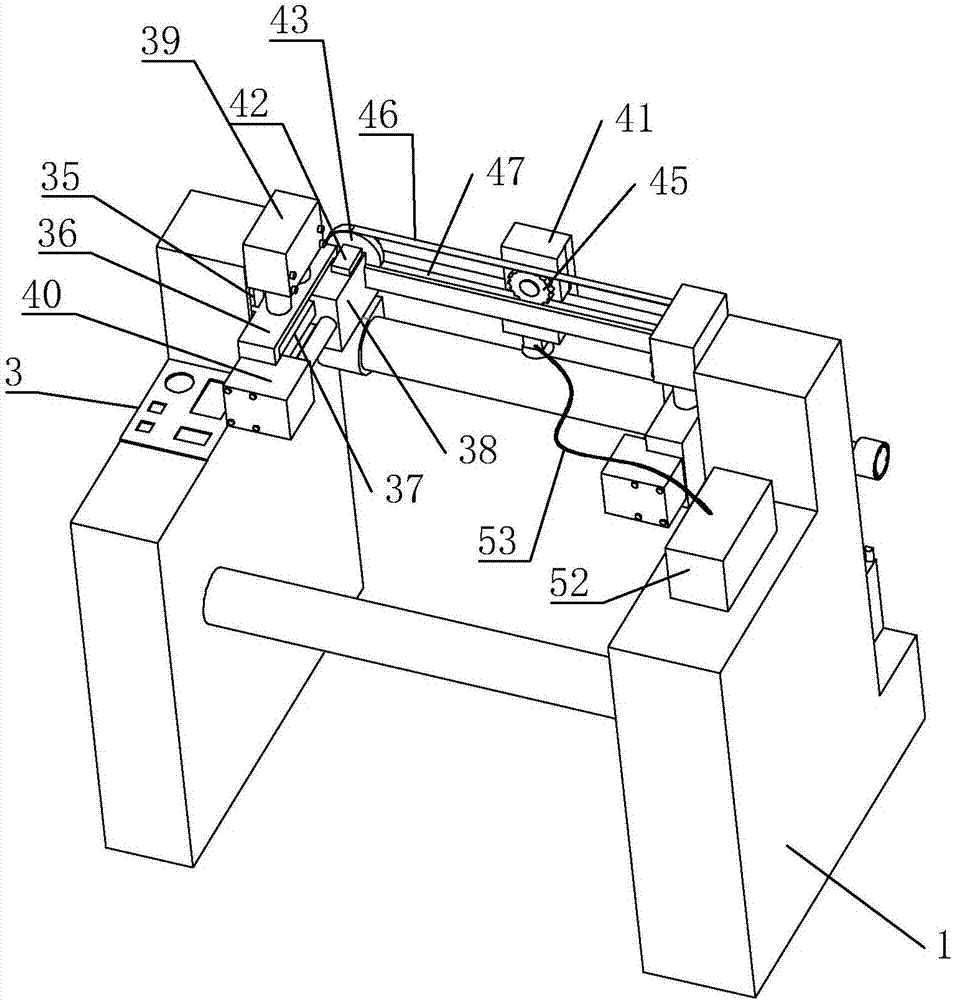

[0050] refer to Figures 1 to 12 As shown, a kind of fully automatic winding machine of the present embodiment, comprises frame 1 and the winding roller 2 that is arranged on frame 1 and controller 3, and described frame 1 is provided with and is parallel to winding roller 2 The crossbar 34 of the crossbar 34, the two ends of the crossbar 34 on the frame 1 are respectively provided with vertical slide rails 35, and the inside of the slide rails 35 are all provided with mutually matching adjustment blocks 36, two adjustment blocks 36 Corresponding two faces are all provided with transverse groove 37, and described transverse groove 37 is respectively provided with moving block 38, and the fourth air cylinder 39 is all installed on two regulating blocks 36, and the air rod of two fourth air cylinder 39 Connect the corresponding moving blocks 38 respectively, and the fourth cylinder 39 can drive the moving blocks 38 to move back and forth on the adjusting block 36. The two ends o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com