Driving mechanism of variable distance turn lock of special transport case lifting tool

A technology of a driving mechanism and a transport box, applied in the field of spreaders, can solve the problems of inaccurate travel of the geared motor and the inability of the spreader to be hoisted, and achieve the effect of improving the use efficiency of the spreader

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

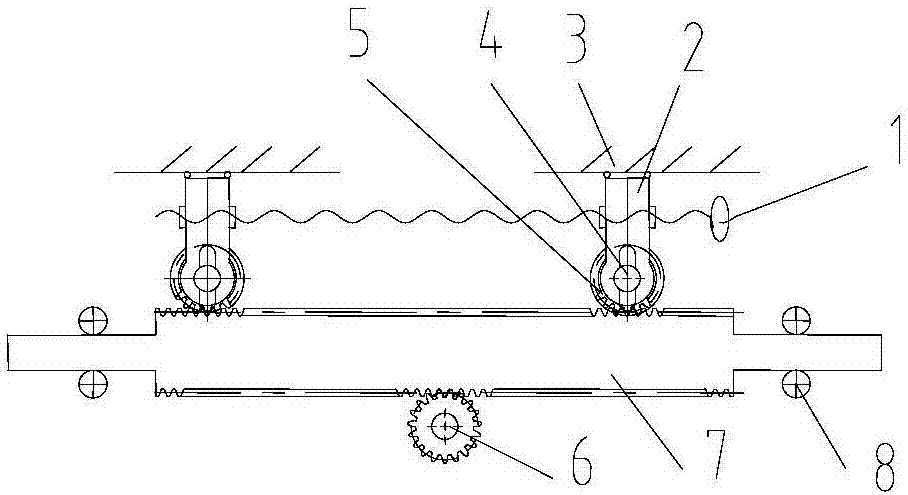

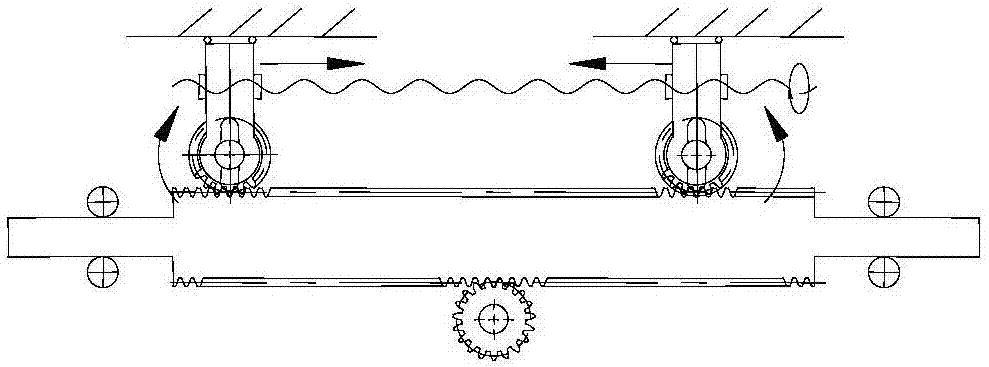

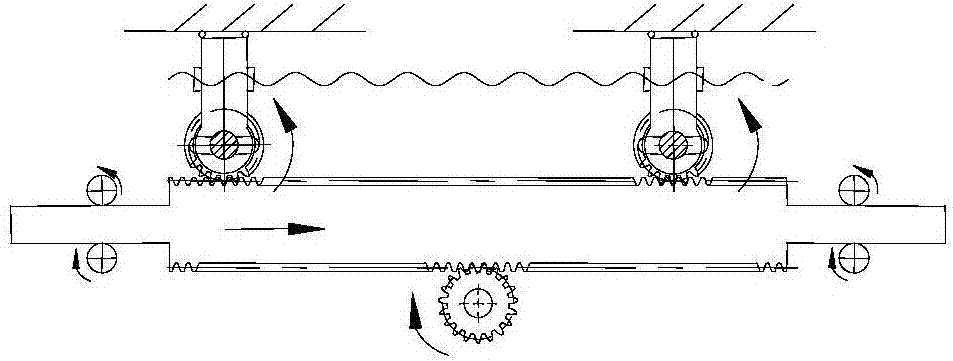

[0012] The technical scheme of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0013] Such as figure 1 As shown, the present invention discloses a variable-pitch turnlock drive mechanism for a special transport box spreader, including a screw nut pair 1, two sliders 2, a slide rail 3, two turnlock shafts 4, and two turnlock shafts Gear 5, driving gear 6, rack 7, rack guide support 8, the nut of the screw nut pair 1 is fixed on the slider 2, the slider 2 can move along the slide rail 3, and the turn lock shaft 4 Installed in the lower end of the slider 2, the turn lock shaft 4 can rotate on the slider 2, the turn lock shaft 4 is equipped with a turn lock shaft gear 5, the rack 7 is a double-sided rack, and the lock shaft gear 5 is located on One side of the rack 7 meshes with the rack 7, and the other side of the rack 7 meshes with the driving gear 6, and the driving gear 6 is self-locking and stationary without power in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com