Honeycomb core mounting construction method

A construction method and honeycomb core technology, which is applied to building components, floors, buildings, etc., can solve the problems of inconvenient follow-up construction and low reliability of honeycomb core connection, and achieve the effect of increasing positional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

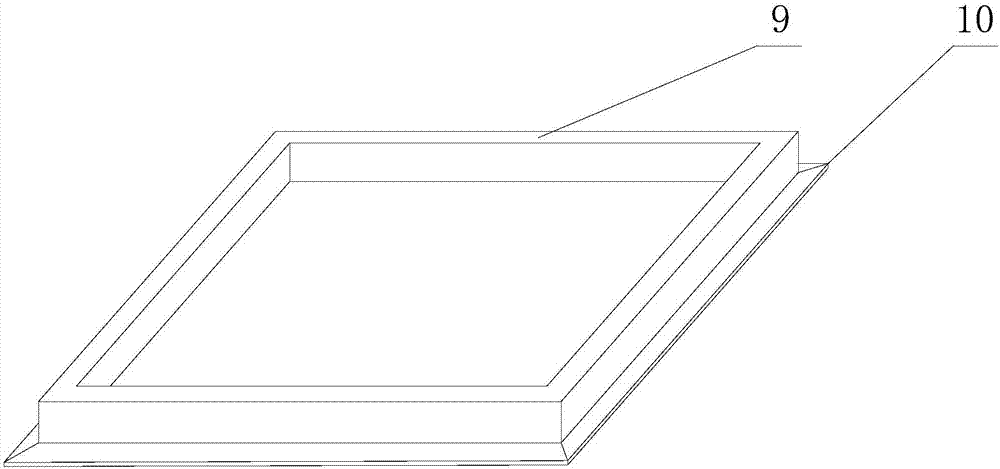

[0042] Such as image 3 As shown, a construction method for installing a honeycomb core, including step S1: erecting a formwork; step S3: placing the honeycomb core on the formwork, and step S2: setting bottom constraints for the honeycomb core on the formwork;

[0043] The step S2 is located between the steps S1 and S3 or after the step S3;

[0044] When step S2 is located between steps S1 and S3, step S2 is to set the surrounding edge 9 around the installation position of the honeycomb core, so that after the honeycomb core is placed at the installation position, all sides around the honeycomb core are connected to the inside of the surrounding edge 9 touch;

[0045] When the step S2 is located after the step S3, the step S2 is to set the surrounding edge 9 around the honeycomb core, and each side of the honeycomb core is in contact with the inner side of the surrounding edge 9;

[0046] The connection relationship between the surrounding edge 9 and the template is a detac...

Embodiment 2

[0049] This embodiment is further limited on the basis of the technical solution provided in embodiment 1, as image 3 As shown, as a specific implementation scheme of the surrounding edge 9, the surrounding edge 9 is a frame-like structure surrounded by wooden boards, and the connection mode between the surrounding edge 9 and the formwork adopts any one or several of the following methods : Tenon connection, iron nail connection, screw connection;

[0050] When using iron nails or screws, the iron nails and screws are embedded in the surrounding edge 9 upwards from the bottom of the formwork. In this solution, the surrounding edge 9 can be made of waste templates, which has the characteristics of convenient material acquisition and low cost; the specific solution of the above detachable connection method has low cost and high realization efficiency. Specifically, when tenon joints are used, a circular blind hole can be drilled on the upper side of the formwork as a tenon gro...

Embodiment 3

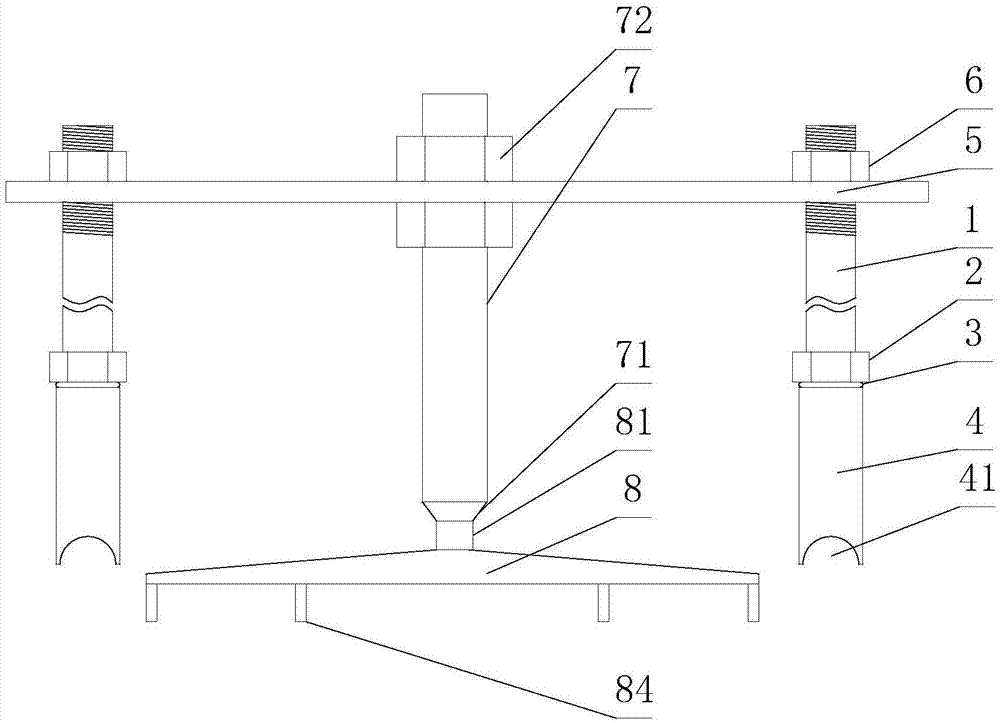

[0054] Such as Figure 1 to Figure 3 As shown, this embodiment is further defined on the basis of the technical solution provided in Embodiment 1, as a step for implementing vertical constraints on the honeycomb core, it also includes step S4: setting top constraints for the honeycomb core , the top constraint is used to apply downward compressive stress to the top surface of the honeycomb core.

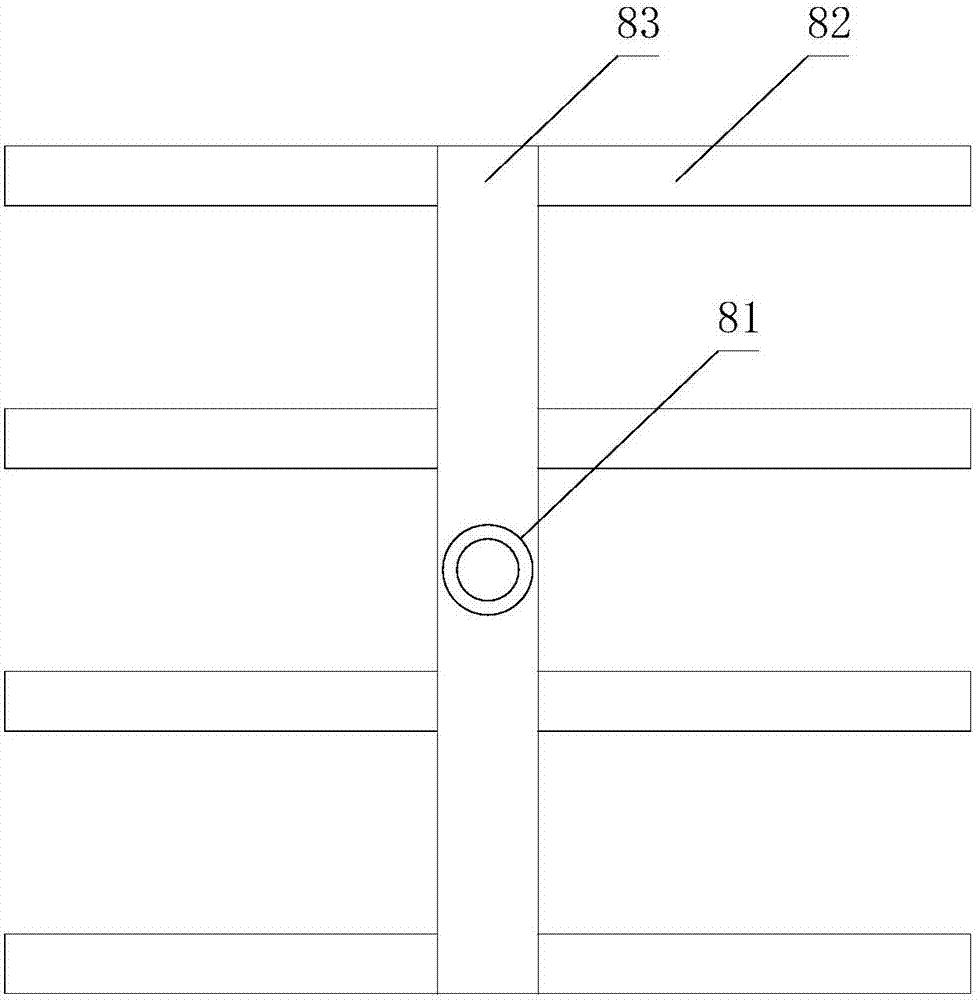

[0055] As a specific implementation of the top constraint, the top constraint includes a frame body connected to the floor steel mesh, a compression bar 7 connected to the frame body at the upper end, and a compression plate 8 for placing on the upper surface of the honeycomb core;

[0056] Described frame body comprises vertical rod and crossbeam 5, and described vertical rod comprises connecting seat 4 and column 1, and described connecting seat 4 is provided with internally threaded hole, and the lower end of column 1 is threadedly connected with internally threaded hole, and desc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com