Bidirectional displacement hydraulic motor with speed limiting device

A speed limiting device and hydraulic motor technology, which is applied in the field of hydraulic motors and bidirectional displacement hydraulic motors, can solve problems such as motor impact, equipment safety accidents, and motor damage, and achieve the effect of preventing damage and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

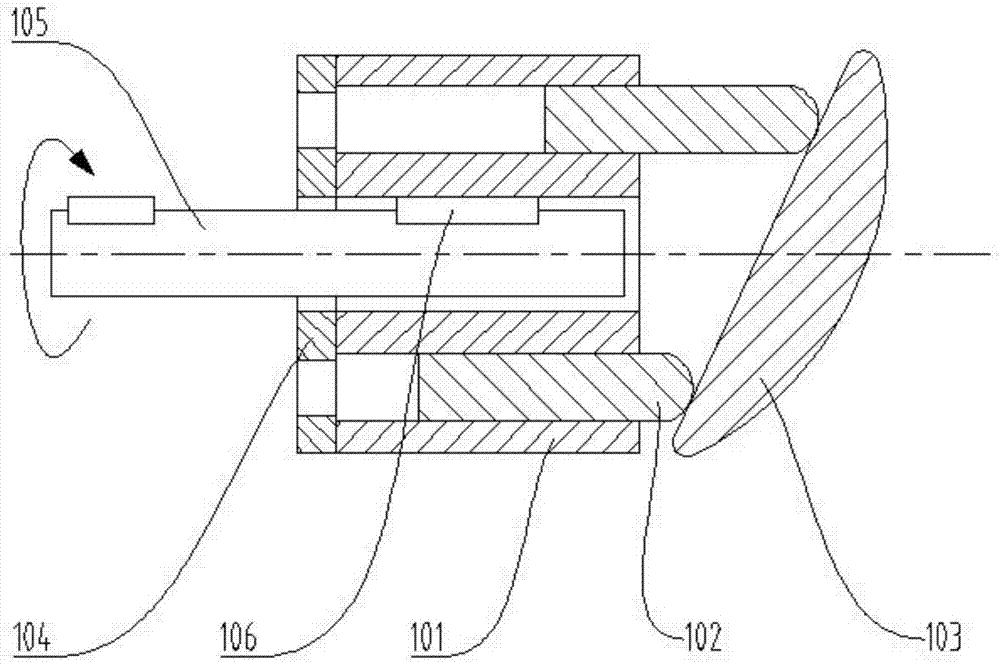

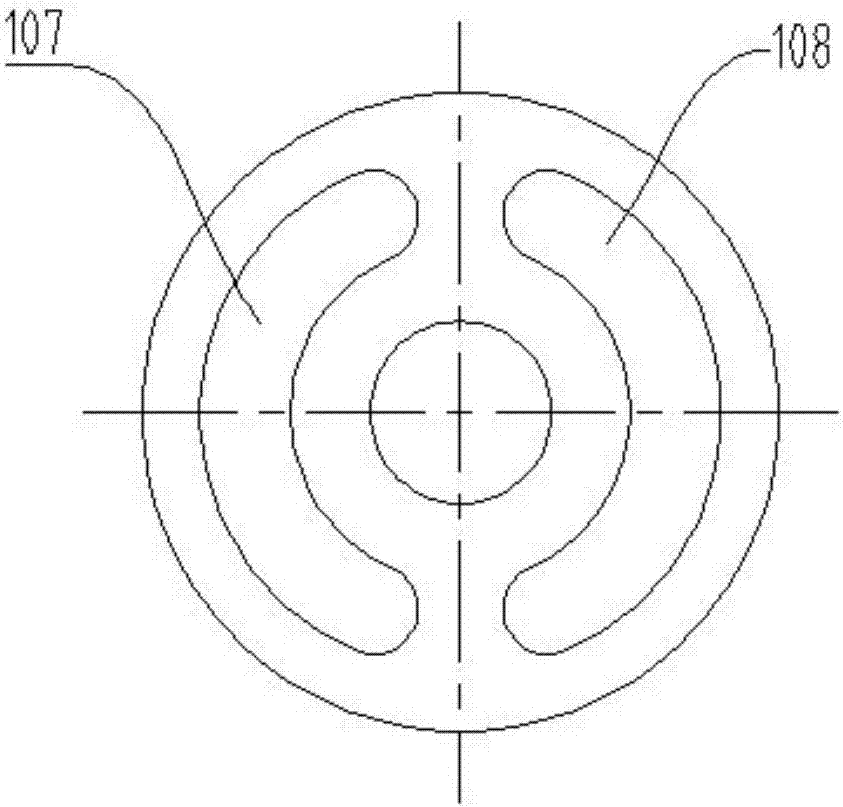

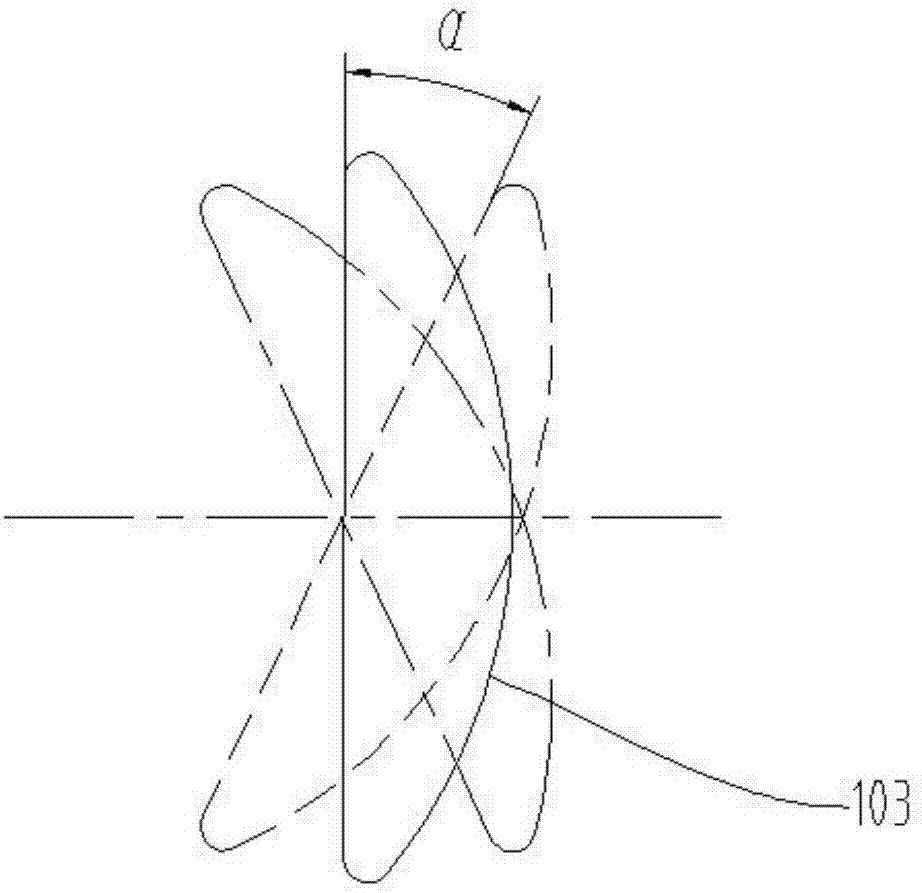

[0024] Such as Figures 3 to 5 As shown, a two-way displacement hydraulic motor with a speed limiting device includes a motor body 1 and a casing 2. The motor body 1 includes a cylinder block 101, an output shaft 105, a plunger 102, a swash plate 103, and a valve plate 104. The cylinder block 101 distributes several round holes evenly along the radial direction, the plunger 102 is installed in the round hole, and one end of the plunger 102 acts on the swash plate 103; the cylinder body 101 is closely matched with the distribution plate 104, and the distribution plate 104 has an oil hole 107, the output shaft 105 is connected to the cylinder body 101 through a key 106; a speed limiting device is installed in the casing 2, and the speed limiting device includes a bypass valve 3 and a lever mechanism 4, and a roller I32 is installed at the lower end of the spool 31 of the bypa...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap