Medicinal material sterilizing and drying device

A drying device and technology for medicinal materials, applied in the direction of drying gas arrangement, biomass drying, drying solid materials, etc., can solve the problems of mildew of medicinal materials, inability to completely remove medicinal materials, loss of medicinal material production enterprises, etc., and achieve the effect of rapid drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

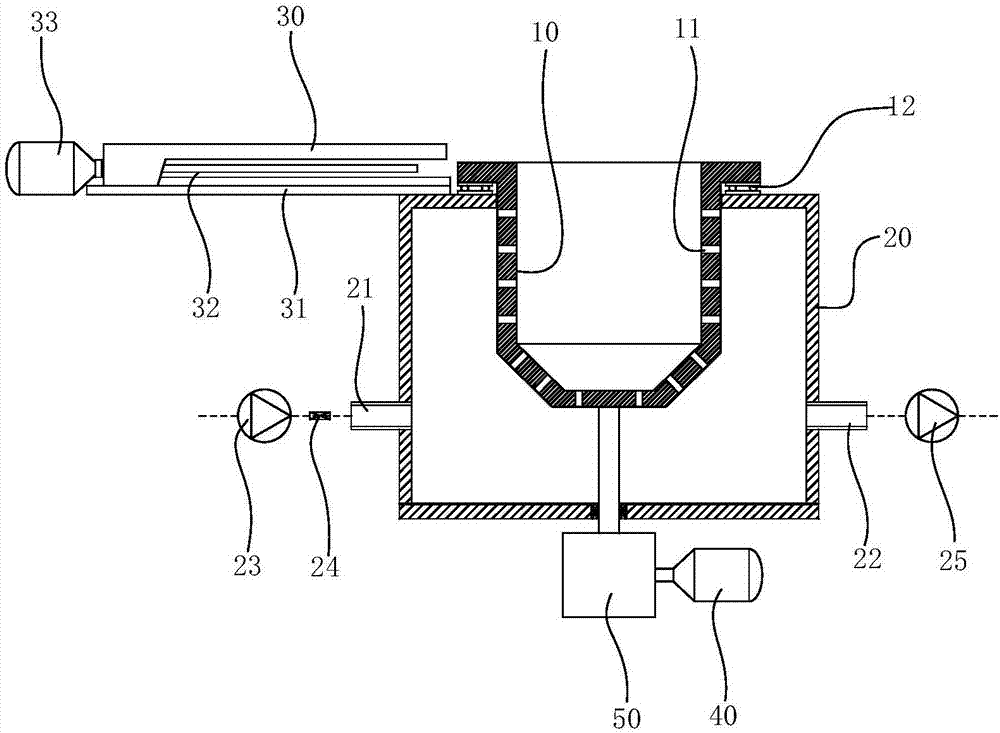

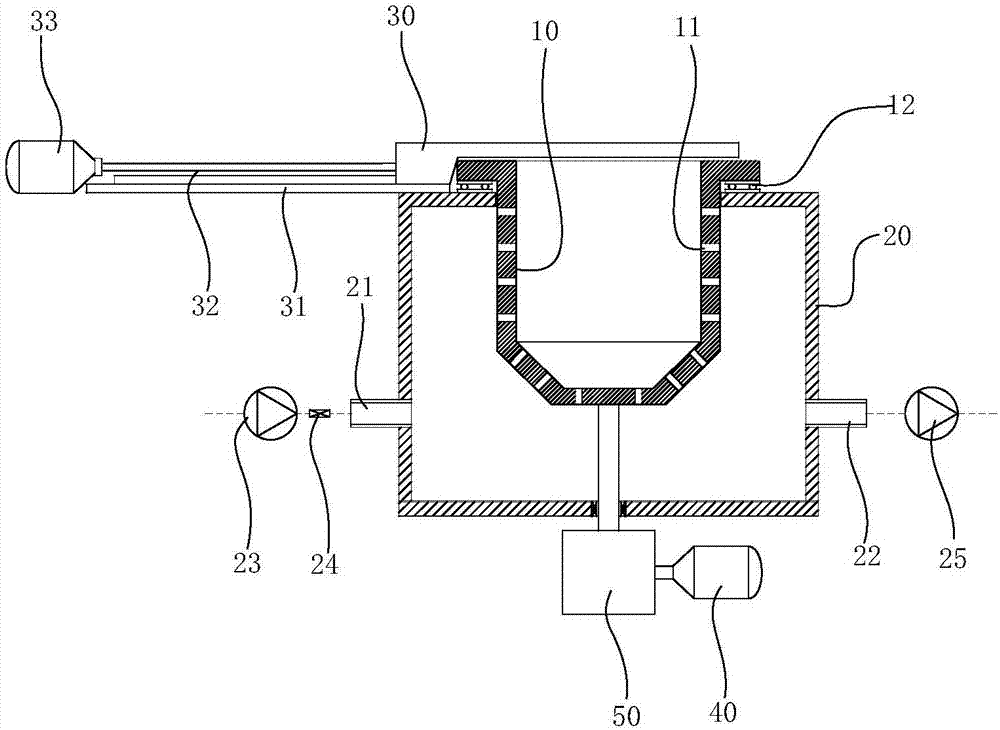

[0011] refer to figure 1 and figure 2 , the structural characteristics of the medicinal material sterilization and drying device are described in detail as follows:

[0012] The device for sterilizing and drying medicinal materials includes a vertically arranged drying cylinder 10, and a plurality of ventilation holes 11 are opened on the circumference and bottom of the cylinder wall of the drying cylinder 10. The drying cylinder 10 is connected with a driving mechanism, and the driving mechanism drives the drying cylinder 10 around The cylinder core rotates, and the drying cylinder 10 is provided with a sealing box 20, and the sealing box 20 is respectively provided with an air inlet 21 and an air outlet 22, and the mouth of the drying cylinder 10 is provided with a sealing cover plate 30 , the power mechanism drives the sealing cover plate 30 to reciprocate horizontally and implements the sealing and opening of the mouth of the drying cylinder 10;

[0013] During the ster...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com