Nut beverage production line and production method

A production line and beverage technology, applied in packaging, packaging protection, food science, etc., can solve problems such as increasing process costs, affecting production efficiency, and consuming manpower, so as to improve disinfection and sterilization efficiency, improve recycling efficiency, and ensure circulation and circulation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

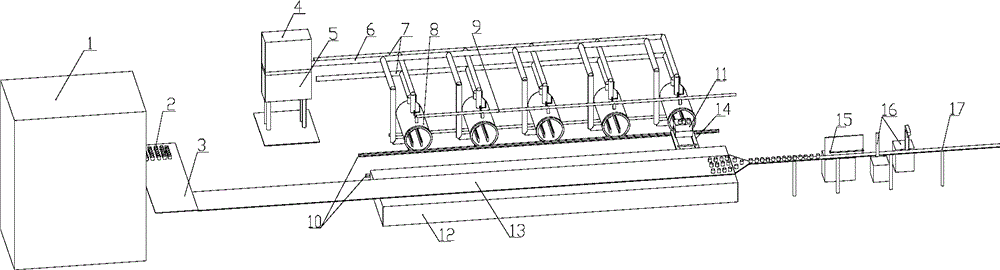

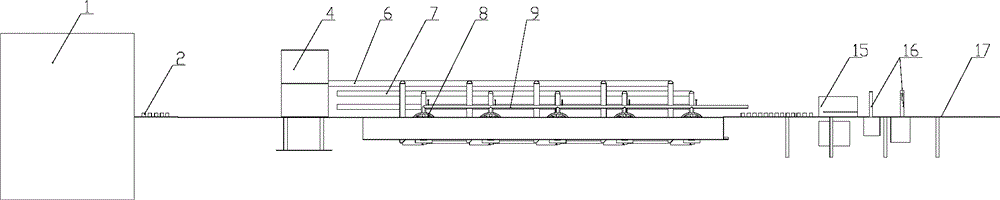

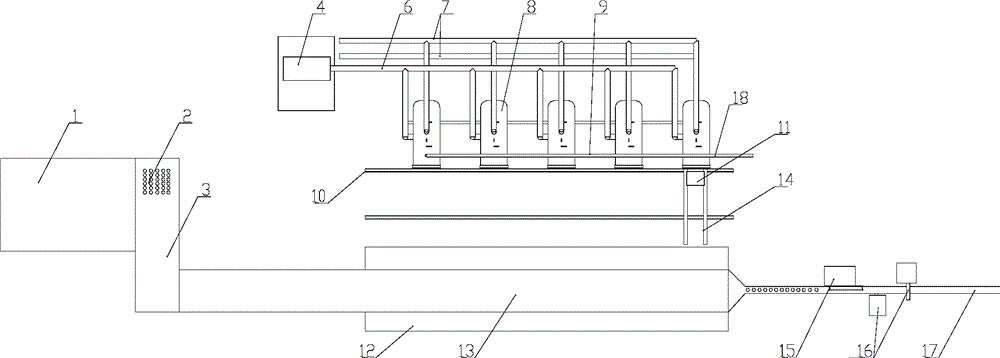

[0051] join Figure 1-3 , a kind of nut beverage production line, it comprises canning and sealing equipment 1, through canning and sealing equipment 1, the nut whey is sealed and canned, and a conveyor belt 3 is installed at the outlet of canning and sealing equipment 1, through a Canned beverage 2 is transported by the No. 1 conveyor belt 3, and the No. 1 conveyor belt 3 is connected with a vertical transfer belt 13, and the vertical transfer belt 13 is installed on the workbench 12, and the canned beverages that have been filled will be packed by the vertical transfer belt 13. Beverage 2 is transported to the workbench 12 to facilitate the sterilization operation in the latter step. A No. 1 track 10 is arranged on the left side of the workbench 12, through which the canned drinks on the workbench 12 can be conveniently processed. 2 for transportation, thereby improving transportation efficiency and saving manpower; multiple sterilizing cooling devices 8 are installed on the...

Embodiment 2

[0053] see Figure 4-6 , the sterilizing cooling device 8 includes a tank body 801, the tank body 801 is fixedly installed on the base 802, the front opening of the tank body 801 is provided with a sealed door 805, and the top end of the tank body 801 near the opening is provided with a cooling water inlet 806, On the left side of the cooling water inlet 806, there is a No. 1 vent pipe 807, a No. 1 pressure relief valve 808 is installed on the No. 1 vent pipe 807, a No. 1 manometer 809 is arranged on the left side of the No. 1 vent pipe 807, and No. 1 manometer 809 No. 1 high-pressure gas inlet 810 is set on the left side of the No. 1 high-pressure gas inlet 810, and No. 2 manometer 811 is set on the left side of No. 1 high-pressure gas inlet 810. No. 2 air release pipe 813 is arranged on the left side of No. 2 manometer 811, and No. 2 air release pipe 813 There is a No. 2 pressure relief valve 812 on the top, No. 2 high-pressure gas inlet 814 is set on the top end of the tank...

Embodiment 3

[0057] see Figure 7 , the cleaning device 15 includes a nozzle bracket 1502, a nozzle 1501 is installed on the nozzle bracket 1502, a plurality of high-pressure nozzles 1503 are arranged on the nozzle 1501, a water valve 1504 is arranged at the water inlet of the nozzle 1501, and a high-pressure water pipe One end of 1505 is connected with spray pipe 1501, and the other end is connected with high-pressure water pump 1506.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com