Method and system for air sterilization and purification of semiconductor thermoelectric sheet

An air sterilization, semiconductor technology, applied in air conditioning systems, heating methods, air quality improvement and other directions, can solve the problems of low energy utilization efficiency, not effectively applied, etc., achieve high energy utilization efficiency, high energy utilization rate, improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Such as figure 1 As shown, a method for applying semiconductor thermoelectric chips to the design of air sterilization and purification systems includes the following parts:

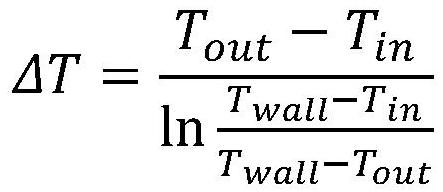

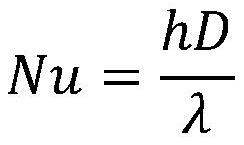

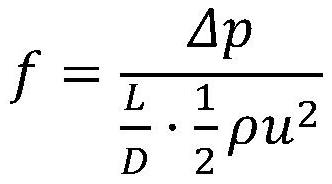

[0067] (1) Determine the application direction and the temperature of the cold end and hot end to be achieved, select the appropriate semiconductor thermoelectric sheet, and adjust the temperature range by testing the current size to meet the required requirements. One of the conditions for judgment is: thermoelectric sheet Whether the temperature range of the hot end and the temperature range of the cold end can reach the required temperature range, that is, the temperature range of the hot end is the air sterilization temperature, and the temperature range of the cold end is the output air temperature. The output air temperature can be determined according to the output air temperature. The application scenario is determined, such as the comfortable temperature of the human body. In the present...

Embodiment 2

[0099] Such as figure 2 As shown, a semiconductor thermoelectric sheet air sterilization and purification system related to this embodiment includes a plurality of semiconductor thermoelectric sheets 2 arranged in an array, an air sterilization and purification flow channel, and an air output flow channel, wherein the semiconductor thermoelectric sheet 2 is energized The temperature range of the last hot end includes the air sterilization temperature, and the temperature range of the cold end after the semiconductor thermoelectric sheet 2 is energized includes the output air temperature; the hot end of the semiconductor thermoelectric sheet 2 is placed in the air sterilization and purification flow channel, so The cold end of the semiconductor thermoelectric chip 2 is placed in the air output flow channel, and the outlet of the air sterilization and purification flow channel is connected with the inlet of the air output flow channel, in this way, the air flow to the air steril...

Embodiment 3

[0102] Such as Figure 5 with Image 6 As shown, a semiconductor thermoelectric sheet air sterilization and purification system related to this embodiment includes a plurality of semiconductor thermoelectric sheets 2 arranged in an array, an air sterilization and purification flow channel 5 and an air output flow channel 6, wherein the semiconductor thermoelectric sheet 2. The temperature range of the hot end after energization includes the air sterilization temperature, and the temperature range of the cold end after the semiconductor thermoelectric sheet 2 is energized includes the output air temperature; the hot end of the semiconductor thermoelectric sheet 2 is placed in the air sterilization and purification flow channel 5, the cold end of the semiconductor thermoelectric sheet 2 is placed in the air output flow channel 6, and the outlet of the air sterilization and purification flow channel 5 is connected with the inlet of the air output flow channel 6, in this way, to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com